Belt storage type crawler travelling conveyor and travelling method thereof

A conveyor and belt storage technology, applied in the direction of conveyors, conveyor objects, cleaning devices, etc., to improve operation stability, avoid repeated installation and disassembly of the head station, and achieve the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

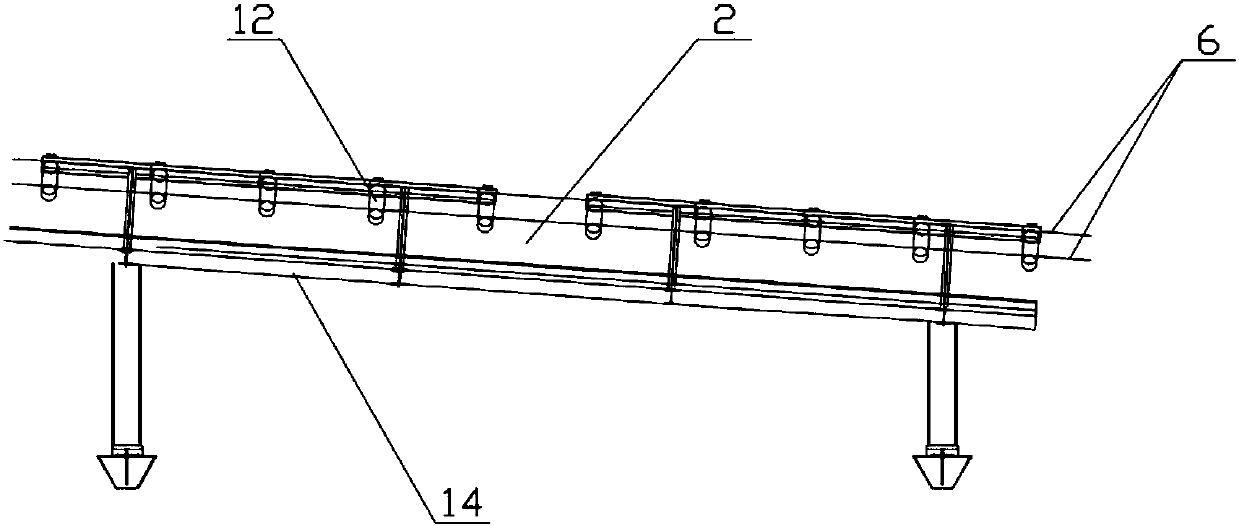

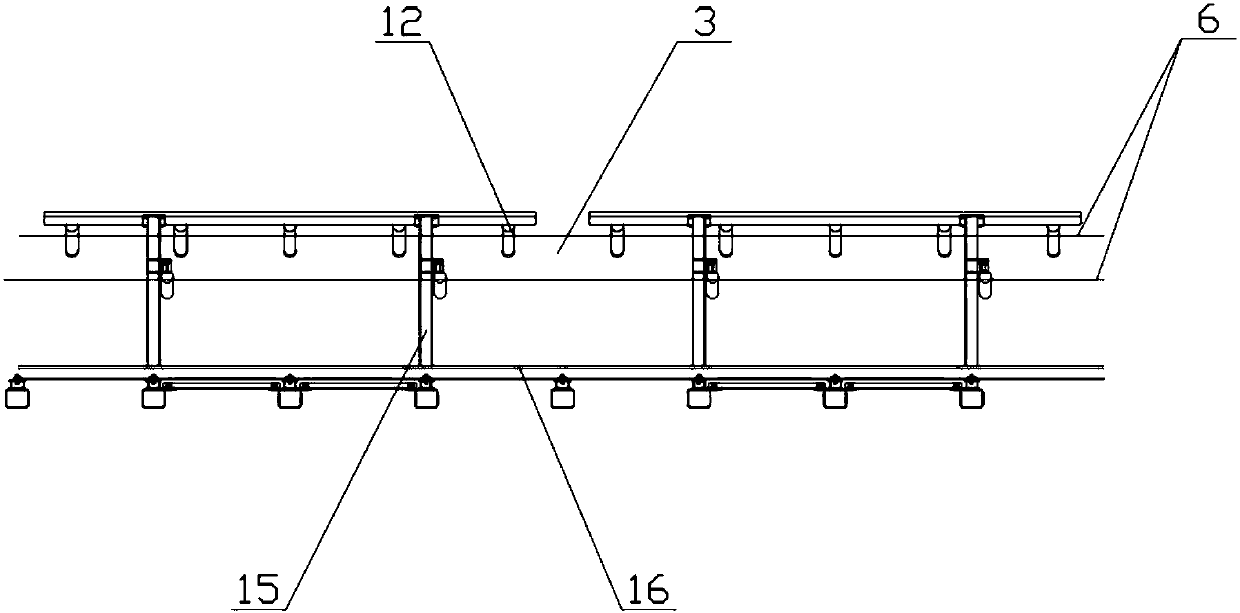

[0044] like Figure 4 As shown, a belt storage type crawler displacement conveyor includes a head station 1, a transition section 2, an intermediate section 3, a belt storage section 4 and a tail station 5 arranged in sequence in the horizontal direction;

[0045] Wherein said belt storage section 4 comprises automatic tensioner 17, carrying roller group 23, storage belt section frame 24 and reversing drum 25, described automatic tensioner 17, described carrying roller group 23 and said automatic tensioner 17 The reversing cylinder 25 described above is all arranged on the described tape storage section frame 24; the quantity of the described tape storage section frame 24 is at least one, and can pass between each described tape storage section frame 24 Bolt connection facilitates the transfer of the belt storage rack 24;

[0046] Described automatic tensioning device 17 comprises steel wire rope 18, tension drum 19, tension dolly 20, second track 21, tension oil cylinder 30 ...

Embodiment 2

[0050] like Figure 4 As shown, a belt storage type crawler displacement conveyor, on the basis of Embodiment 1, also includes a belt support device 22, and the belt support device 22 is a group of idler rollers with a moving frame;

[0051] The belt-supporting device 22 is arranged on the second track 21, and the belt-supporting device 22 can slide on the second track 21; the belt-supporting device 22 is located on the tensioning Between the roller 19 and the diverting roller 25 , the conveyor belt 6 runs through the belt supporting device 22 .

[0052] In this embodiment, the belt support device 22 straddles the second track 21 , and it has no power and can be locked on a certain position of the second track 21 to prevent the conveyor belt 6 from sagging.

Embodiment 3

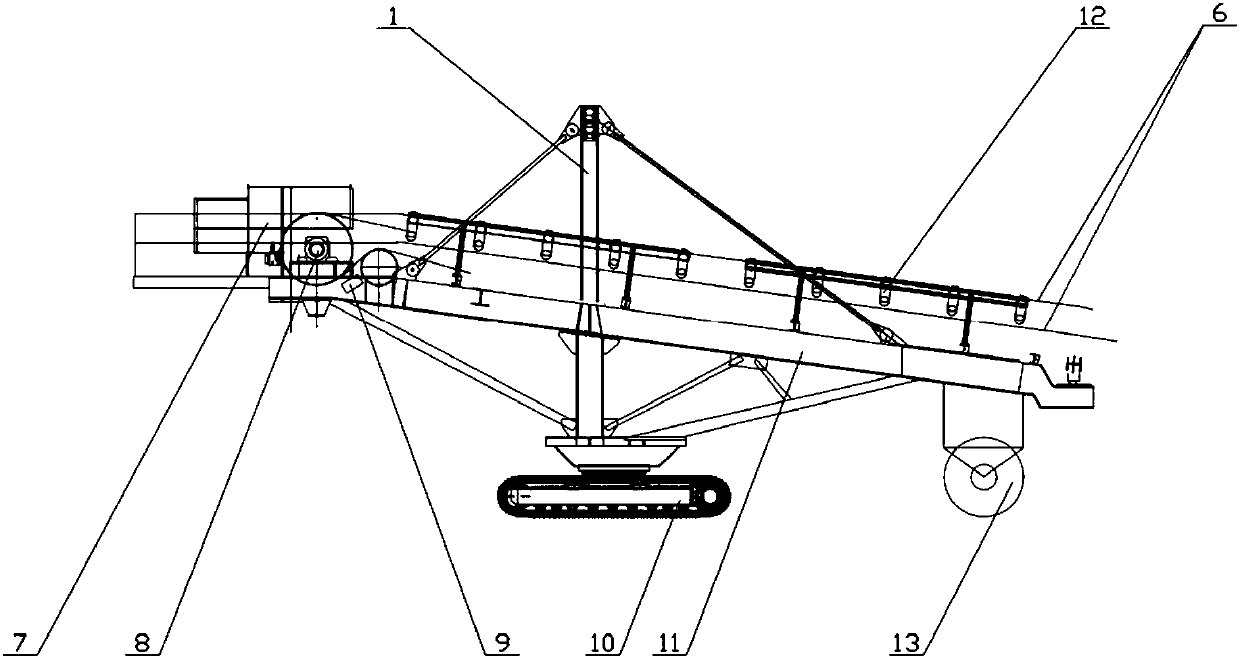

[0054] like figure 1 As shown, a belt storage type crawler displacement conveyor, on the basis of Embodiment 2, the head station 1 includes an unloading device 7, a steering drum 8, a cleaning device 9, a head frame body 11 and a support Roller group 12, the described unloading device 7, the described turning drum 8, the described cleaning device 9 and the described idler roller group 12 are all arranged on the described machine head frame body 11;

[0055] The unloading device 7 and the turning drum 8 are located on the upper part of the head frame body 11 and correspond to the roller group 12, and the cleaning device 9 is located on the turning drum 8 Between the idler roller set 12 and the conveyor belt 6 passes the cleaning device 9 .

[0056] The setting of the cleaning device 9 in this embodiment facilitates the cleaning device 9 to remove the sundries on the conveyor belt 6 after the goods are transported.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com