Method of rapidly preparing NbMoTaW refractory high-entropy alloy material

A high-entropy alloy and refractory technology is applied in the field of preparation of refractory high-entropy alloy materials, which can solve the problems of expensive raw materials, high energy consumption, and large differences in melting points of alloying elements, and achieves fast method, low energy consumption, and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation time of the NbMoTaW high-entropy alloy is less than 30 minutes.

[0038] Each of the raw materials described in the present invention can be obtained by commercial purchase.

Embodiment 1

[0040] the Nb 2 O 5 , MoO 3 , Ta 2 O 5 , WO 3 Mix evenly with Al powder, dry, and compact to obtain a thermite preform with a relative density of 50%. The molar mass ratio of each raw material in the thermite prefab is Nb 2 O 5 : MoO 3 : Ta 2 O 5 : WO 3 : Al = 1:2:1:2:13.66 (x=1, y=1). The obtained thermite preform was loaded into a corundum crucible and placed in an autoclave. Evacuate to the degree of vacuum <1000Pa, and then fill with argon until the pressure of argon is 1MPa. The thermite preform is induced to produce thermite reaction by the heating of the electrified tungsten wire. The aluminothermic reaction obtains a product of upper and lower layers, the upper layer is a ceramic block, and the lower layer is an alloy block. The upper ceramic layer is peeled off to obtain a high-entropy alloy bulk.

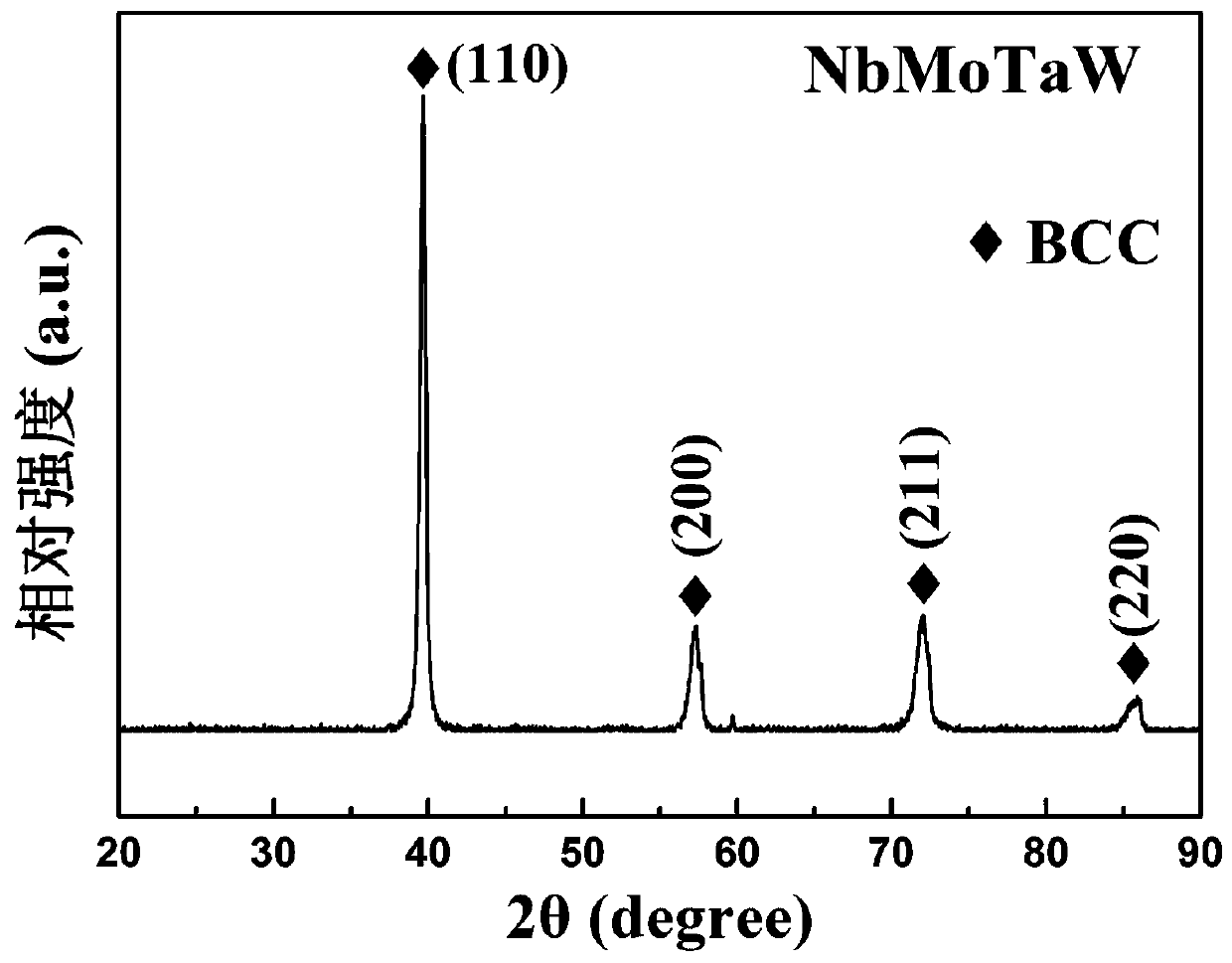

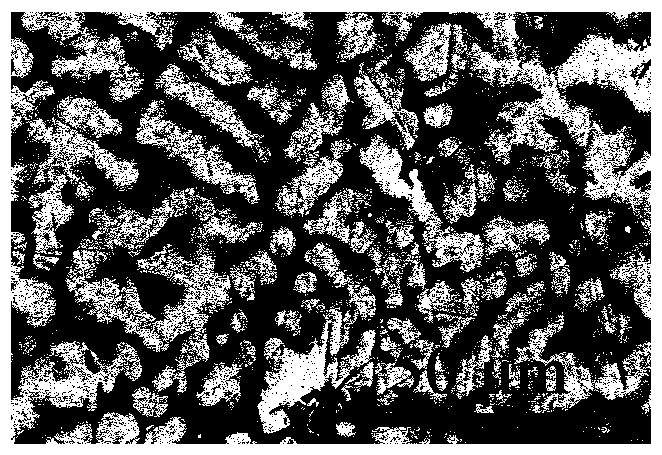

[0041] The obtained high-entropy alloy samples were weighed, measured by density (Archimedes drainage method), and analyzed by XRD and SEM. The component s...

Embodiment 2

[0043] the Nb 2 O 5 , MoO 3 , Ta 2 O 5 , WO 3 Mix evenly with Al powder, dry, and compact to obtain a thermite preform with a relative density of 50%. The molar mass ratio of each raw material in the thermite prefab is Nb 2 O 5 : MoO 3 : Ta 2 O 5 : WO 3 : Al=1:2:1.10:2:13.99 (x=1.10, y=1). The obtained thermite preform was loaded into a corundum crucible and placed in an autoclave. Evacuate to the degree of vacuum <1000Pa, and then fill with argon until the pressure of argon is 1MPa. The thermite preform is induced to produce thermite reaction by the heating of the electrified tungsten wire. The aluminothermic reaction obtains a product of upper and lower layers, the upper layer is a ceramic block, and the lower layer is an alloy block. The upper ceramic layer is peeled off to obtain a high-entropy alloy bulk.

[0044] The obtained high-entropy alloy samples were tested and analyzed, and it was found that the yield of high-entropy alloys was 88.7%, the relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com