Method for homoepitaxially growing monocrystalline diamond on basis of type IIa natural diamond

A single crystal diamond and homoepitaxial technology, applied in the field of diamond, can solve the problem of low purity of carbon source, and achieve the effect of improving purity, improving utilization rate and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

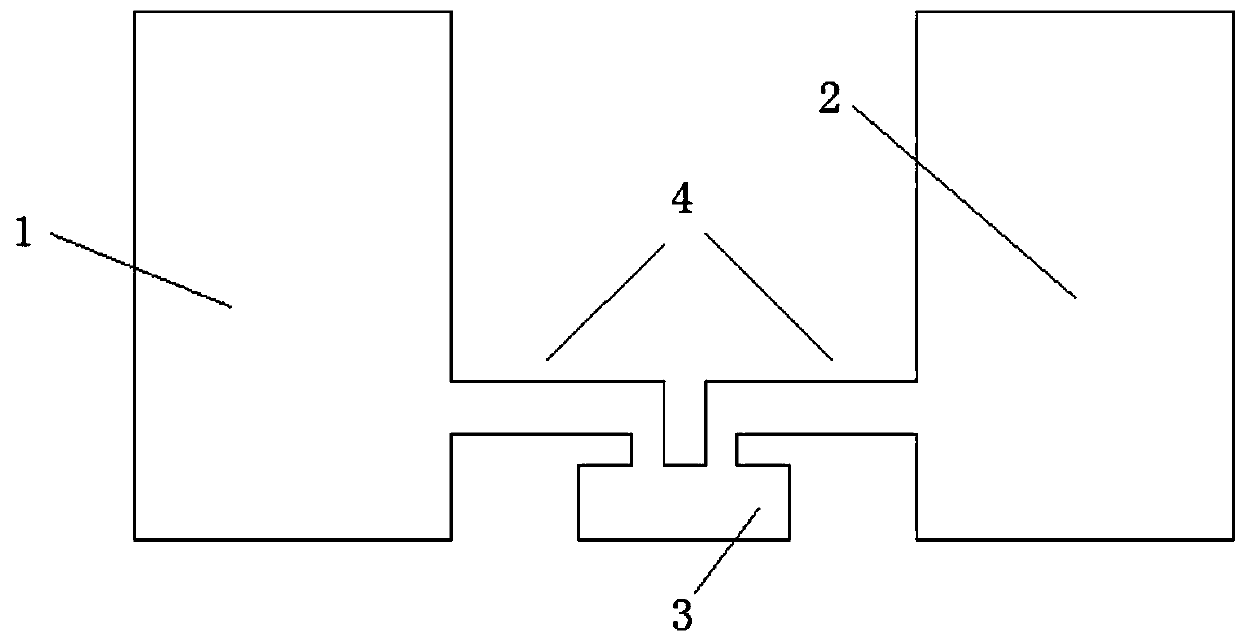

[0024] In the first step, the vacuum chambers of the first microwave plasma chemical vapor deposition device 1 and the second microwave plasma chemical vapor deposition device 2 are communicated with the mechanical pump 3 through the vacuum pipeline 4;

[0025] In the second step, the type IIa natural diamond used as the seed crystal is placed on the sample stage of the first microwave plasma chemical vapor deposition device 1, and the 99.9999% high-purity hydrogen source passes through the hydrogen purification equipment and then passes through the first microwave plasma chemical vapor deposition device. In the reaction chamber of the vapor deposition device 1, the microwave power is adjusted to generate hydrogen plasma, and the process parameters are specifically adjusted as follows: the hydrogen gas flow rate is 300 sccm, the microwave power is 1000 w, and the gas pressure is 18 kPa. Type IIa natural diamond is etched by hydrogen plasma at 1000 ° C. And use the emission spec...

Embodiment 2

[0030] In the first step, the vacuum chambers of the first microwave plasma chemical vapor deposition device 1 and the second microwave plasma chemical vapor deposition device 2 are communicated with the mechanical pump 3 through the vacuum pipeline 4;

[0031] In the second step, the type IIa natural diamond used as the seed crystal is placed on the sample stage of the first microwave plasma chemical vapor deposition device 1, and the 99.9999% high-purity hydrogen source passes through the hydrogen purification equipment and then passes through the first microwave plasma chemical vapor deposition device. In the reaction chamber of the vapor deposition device 1, the microwave power is adjusted to generate hydrogen plasma, and the process parameters are specifically adjusted as follows: the hydrogen gas flow rate is 250 sccm, the microwave power is 1200 w, and the gas pressure is 19 kPa, and the hydrogen plasma at 1050 ° C is used to etch Type IIa natural diamond. And use the em...

Embodiment 3

[0036] In the first step, the vacuum chambers of the first microwave plasma chemical vapor deposition device 1 and the second microwave plasma chemical vapor deposition device 2 are communicated with the mechanical pump 3 through the vacuum pipeline 4;

[0037] In the second step, the type IIa natural diamond used as the seed crystal is placed on the sample stage of the first microwave plasma chemical vapor deposition device 1, and the 99.9999% high-purity hydrogen source passes through the hydrogen purification equipment and then passes through the first microwave plasma chemical vapor deposition device. In the reaction chamber of the vapor deposition device 1, the microwave power is adjusted to generate hydrogen plasma, and the process parameters are specifically adjusted as follows: the hydrogen gas flow rate is 350 sccm, the microwave power is 1500 w, and the gas pressure is 20 kPa, and the hydrogen plasma at 1100 ° C is used to etch type IIa natural diamond. And use the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com