Refuse landfill liner utilizing waste incineration ash and construction method thereof

A technology of waste landfill and waste incineration ash, which is applied in the direction of infrastructure engineering, protection devices, buildings, etc., can solve problems affecting the safety of landfill, slip damage between layers, low bonding strength, etc., and achieve a good ecological environment Compatibility, resistance to deformation and slip damage, effect of reducing land damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

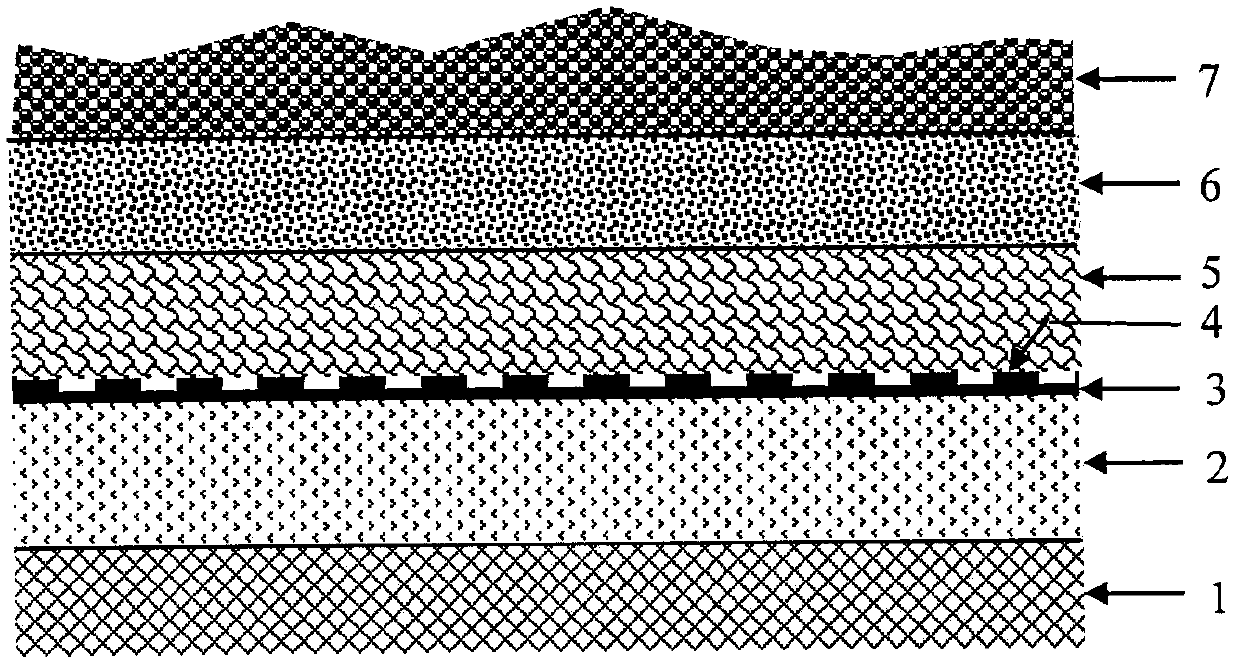

[0033] In this example, a landfill liner and construction method using waste incineration ash is used in a valley-type landfill. The liner structure of the landfill is composed of compacted clay layer 2, Geomembrane 3, geonet 4, solidified fly ash layer 5, waste incineration bottom slag drainage adsorption layer 6, wherein the solidified fly ash layer 5 is made of fly ash particles cemented and solidified after municipal solid waste is incinerated for power generation. The material of the incineration bottom slag drainage adsorption layer 6 is the bottom slag after municipal solid waste is incinerated to generate electricity; the construction method steps of the landfill liner are as follows:

[0034]a. Lay a compacted clay layer 2 with a thickness of 0.8m on the surface of the foundation 1, and lay HDPE material, geomembrane 3 and geonet 4 with a thickness of 2 mm on the top surface of the compacted clay layer 2 from bottom to top;

[0035] b. Lay the fly ash mixture containi...

Embodiment 2

[0044] In this example, a landfill liner and construction method using waste incineration ash is used in a pothole-type landfill, and the landfill liner structure is sequentially composed of compacted clay layers 2 , geomembrane 3, geonet 4, solidified fly ash layer 5, waste incineration bottom slag drainage adsorption layer 6, wherein the material of solidified fly ash layer 5 is cemented and solidified by fly ash particles after municipal solid waste is incinerated for power generation, The material of the waste incineration bottom slag drainage adsorption layer 6 is the bottom slag after municipal solid waste is incinerated to generate electricity; the construction method steps of the landfill liner are as follows:

[0045] a. Lay a compacted clay layer 2 with a thickness of 1.5m on the surface of the foundation 1, and lay HDPE material, a geomembrane 3 and a geonet 4 with a thickness of 2 mm on the top surface of the compacted clay layer 2 from bottom to top;

[0046] b. L...

Embodiment 3

[0055] In this example, a landfill liner and construction method using waste incineration ash is used in a beach-type landfill. The liner structure of the landfill is composed of compacted clay layer 2, Geomembrane 3, geonet 4, microbial solidified fly ash layer 5, waste incineration bottom slag drainage adsorption layer 6, wherein the solidified fly ash layer 5 is made of fly ash particles cemented and solidified after municipal solid waste is incinerated for power generation. The material of the waste incineration bottom slag drainage adsorption layer 6 is the bottom slag after municipal solid waste is incinerated to generate electricity; the construction method steps of the landfill liner are as follows:

[0056] a. Lay a compacted clay layer 2 with a thickness of 1.2m on the surface of the foundation 1, and lay HDPE material, a geomembrane 3 and a geonet 4 with a thickness of 1 mm on the top surface of the compacted clay layer 2 from bottom to top;

[0057] b. Lay the fly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com