Built-in bypass valve body applicable for control of water channels in wall hanging stove system

A technology for waterway control and wall-hung boilers, applied in control valves, devices for pressure relief on sealing surfaces, applications, etc., can solve the problems of increasing the manufacturing cost of waterway modules, increasing external leakage conditions, and high manufacturing and assembly costs , to achieve the effect of simple structure, guaranteeing safety, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

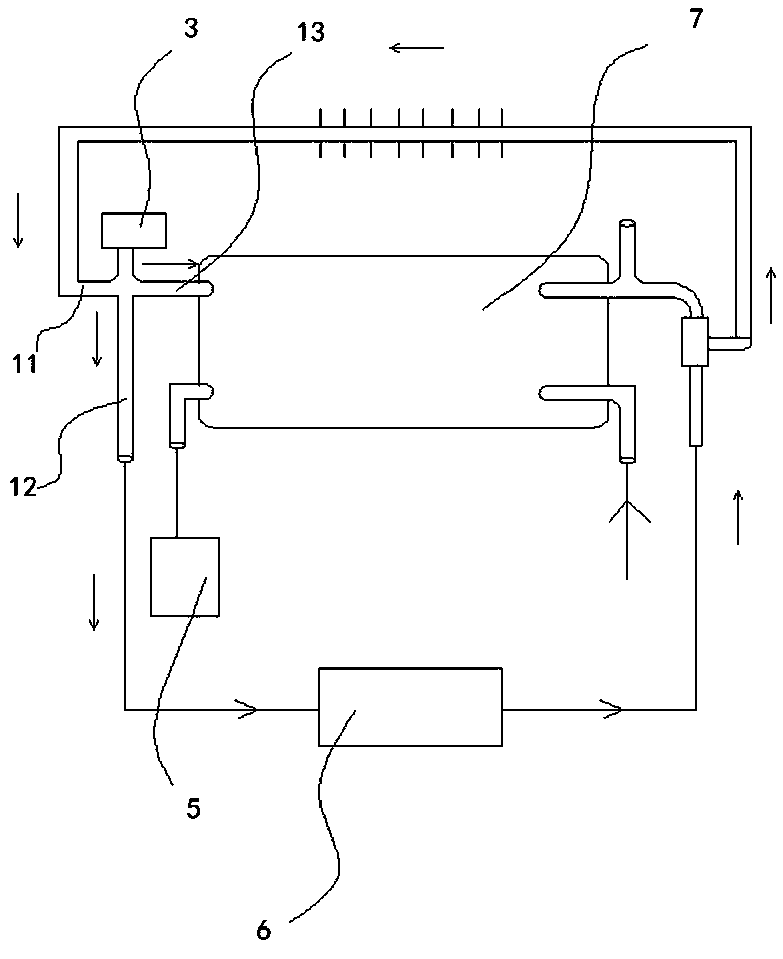

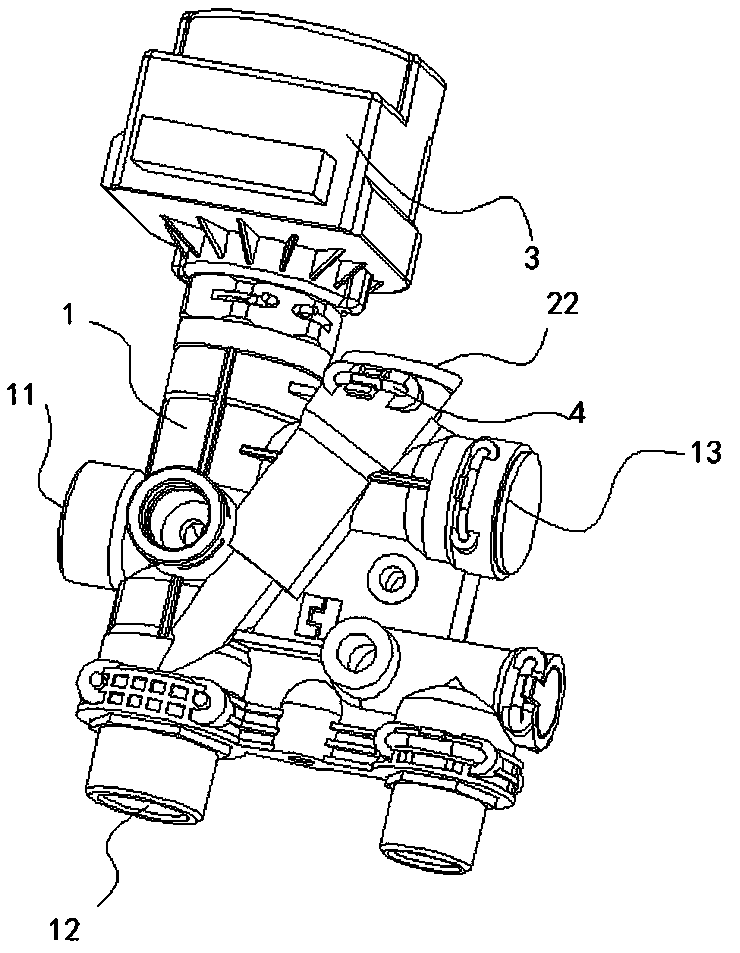

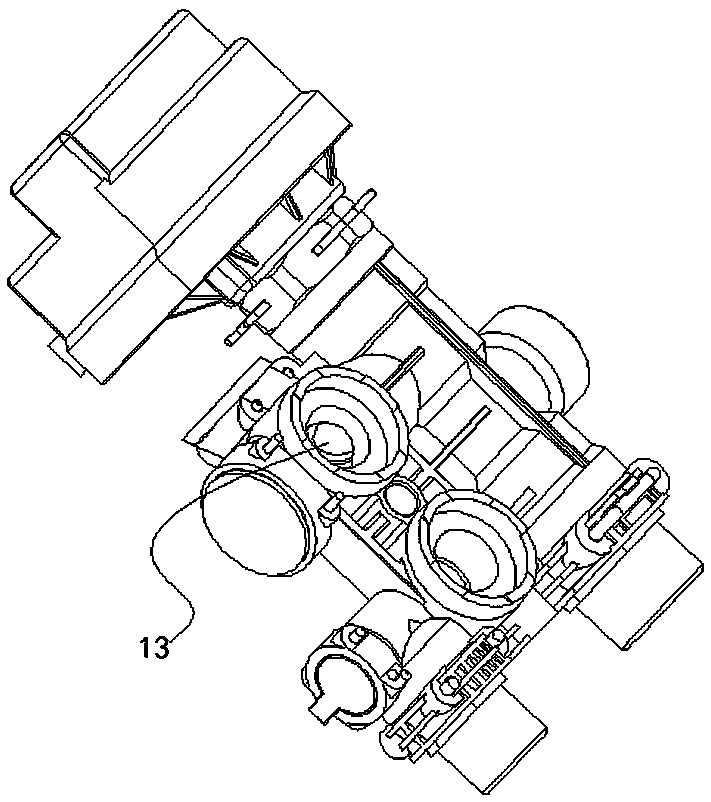

[0034] Please refer to Figure 1 to Figure 12 , the built-in bypass valve body used in the waterway control in the wall-hung boiler system in the figure mainly includes a shell 1 and a bypass mechanism 2; the valve body 1 also includes the existing technology such as the motor 3 and the internal piston and other parts, because the motor 3 and the piston belong to the prior art disclosed by the applicant's previous patent, so no more description is required, as long as the motor 3 and the piston can play a role in the first water outlet channel 12, the second water outlet channel 13 and the water inlet The connection of the channel 11 can be switched, that is, when the water inlet channel 11 is connected with the first water outlet channel 12, the second water outlet channel 13 is not connected with the water inlet channel 11; otherwise, when the water inlet channel 11 is connected with the first water outlet channel When 12 is not connected, the second water outlet channel 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com