Suspension wire variable stiffness micro-nano probe

A technology of variable stiffness and suspension wire, which is applied in the field of micro-nano measurement, can solve the problems of large measurement force, damage to the surface of the workpiece, and small measurement force, achieving high repeatability and precision, meeting measurement requirements, and small return error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

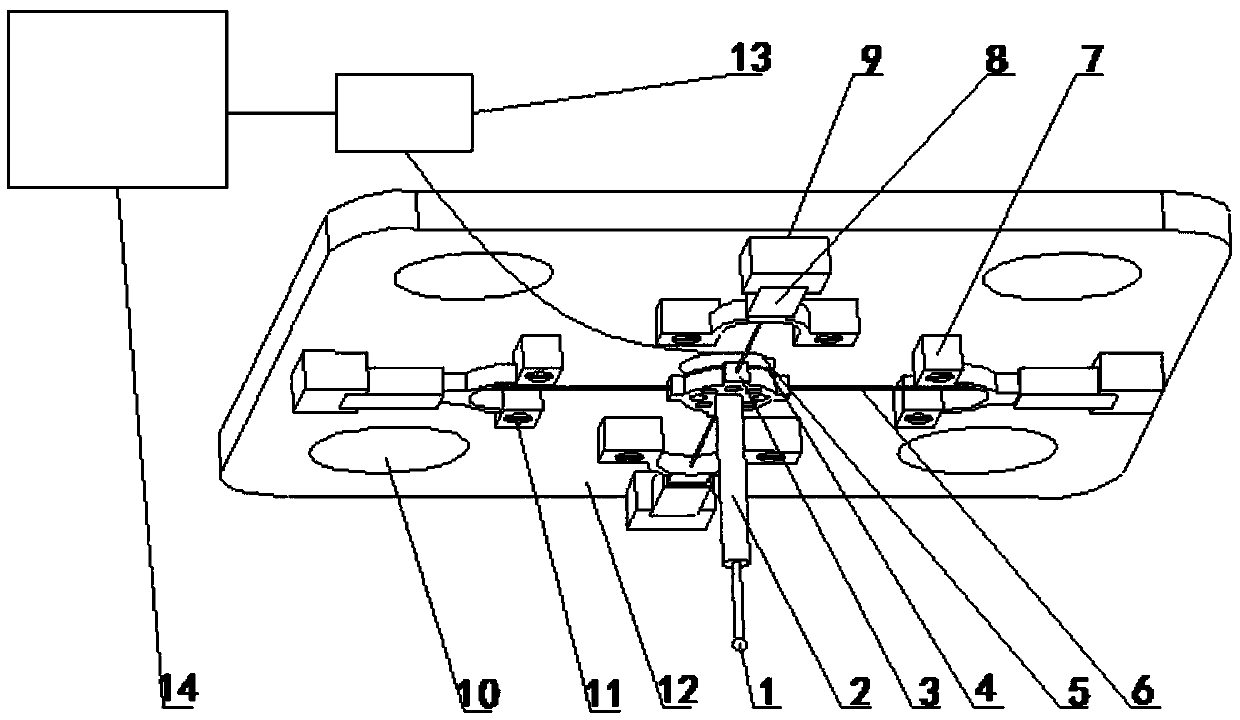

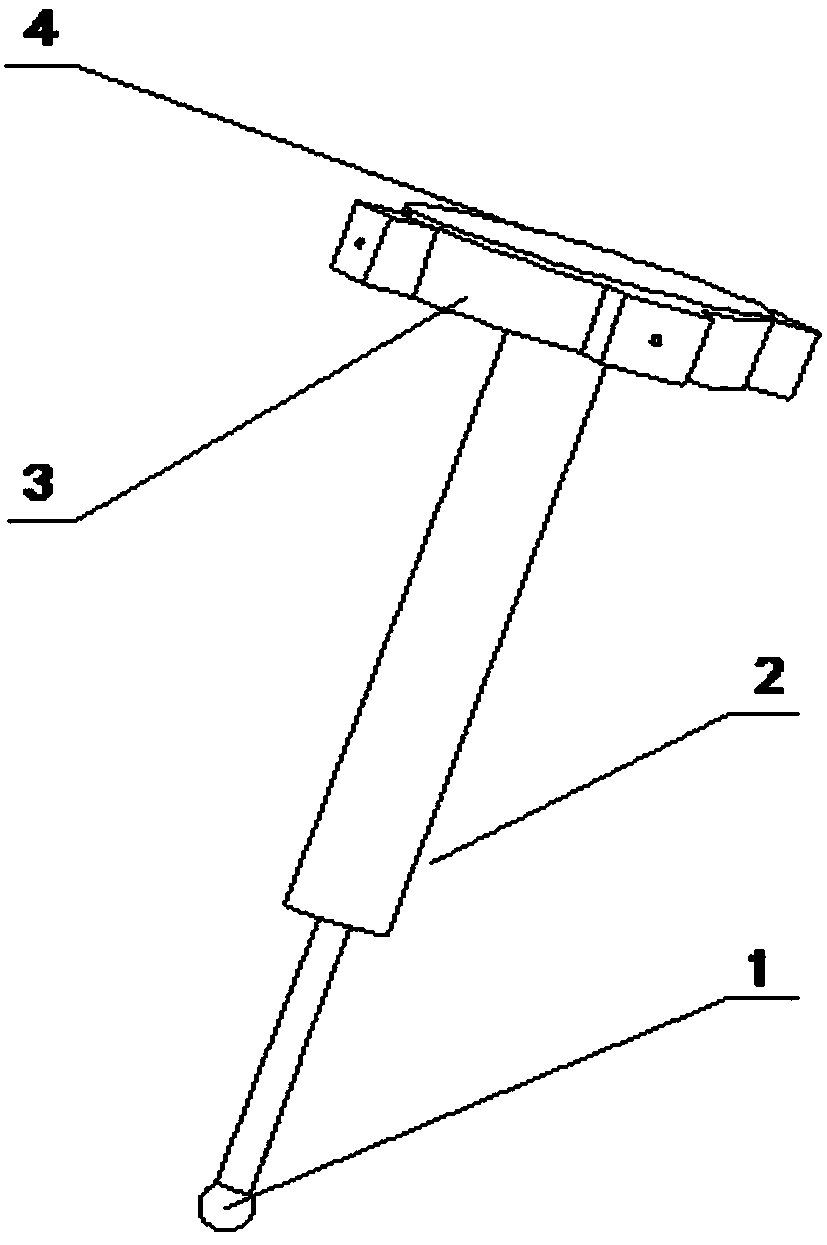

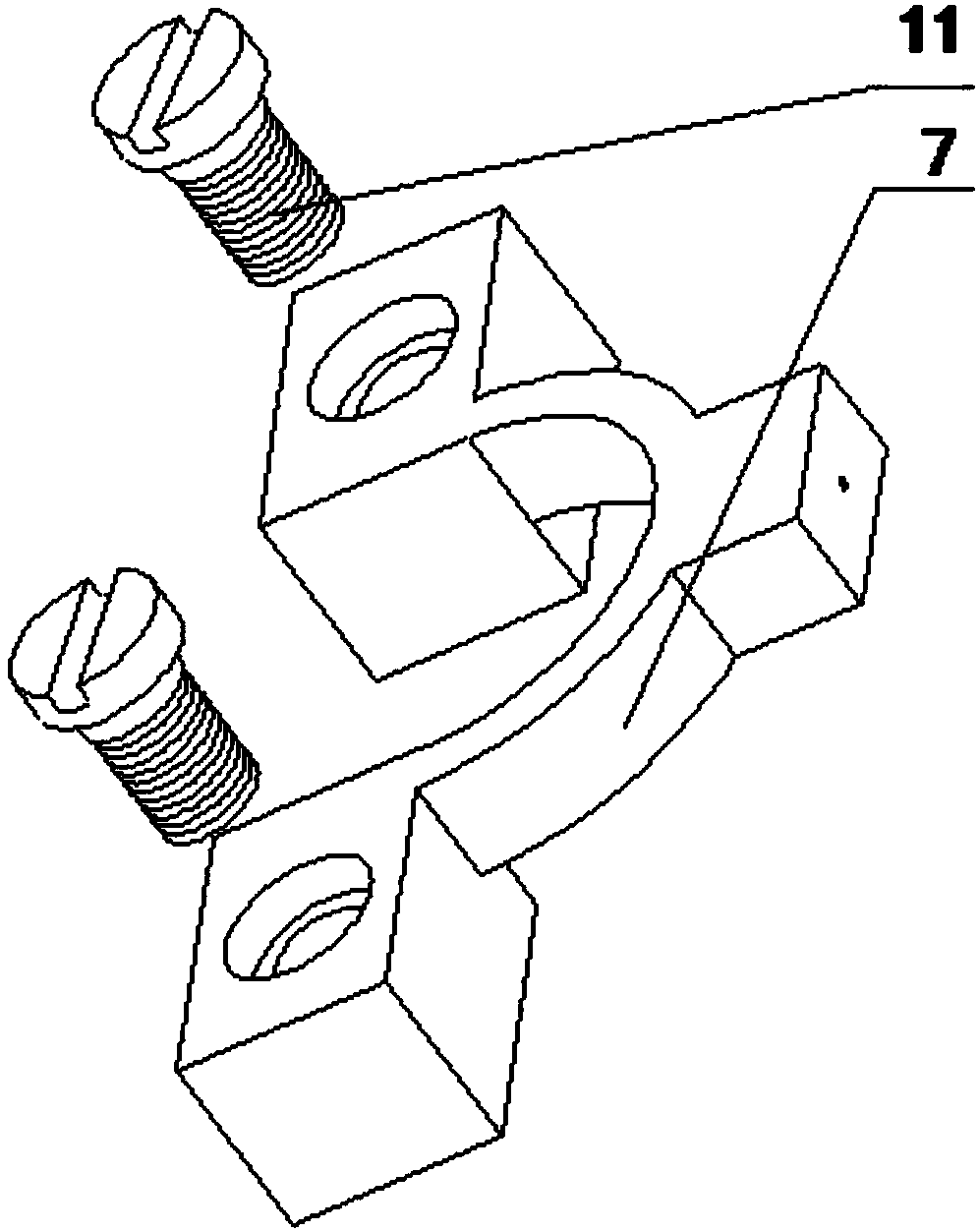

[0014] A suspension wire type variable stiffness micro-nano probe, which mainly includes: probe 1, measuring rod 2, intermediate connector 3, capacitor lower plate 4, capacitor upper plate 5, suspension wire 6, ring-shaped memory alloy 7 , Piezoelectric ceramic chip 8, fixed base 9, bolt hole 10, screw 11, moving platform 12, capacitance-to-digital converter-13, industrial computer-14. The measuring head 1 and the measuring rod 2 are of an integrated structure, a circular groove is arranged at the center of the lower surface of the intermediate connecting body 3, and the measuring rod 2 is cemented to the circular groove of the central connecting body 3 by means of gluing. In order to reduce the quality of the intermediate connecting body 3, eight circular grooves are symmetrically arranged on its lower surface. Four bosses are arranged symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com