Quantum dot LED package structure

A technology of LED packaging and quantum dots, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult liquid crystal display narrow frame display, blue color shift at the edge of backlight, and decrease in fluorescence efficiency, so as to improve luminous efficiency and service life , easy to display with narrow borders, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail the preferred embodiments of the present invention and the accompanying drawings.

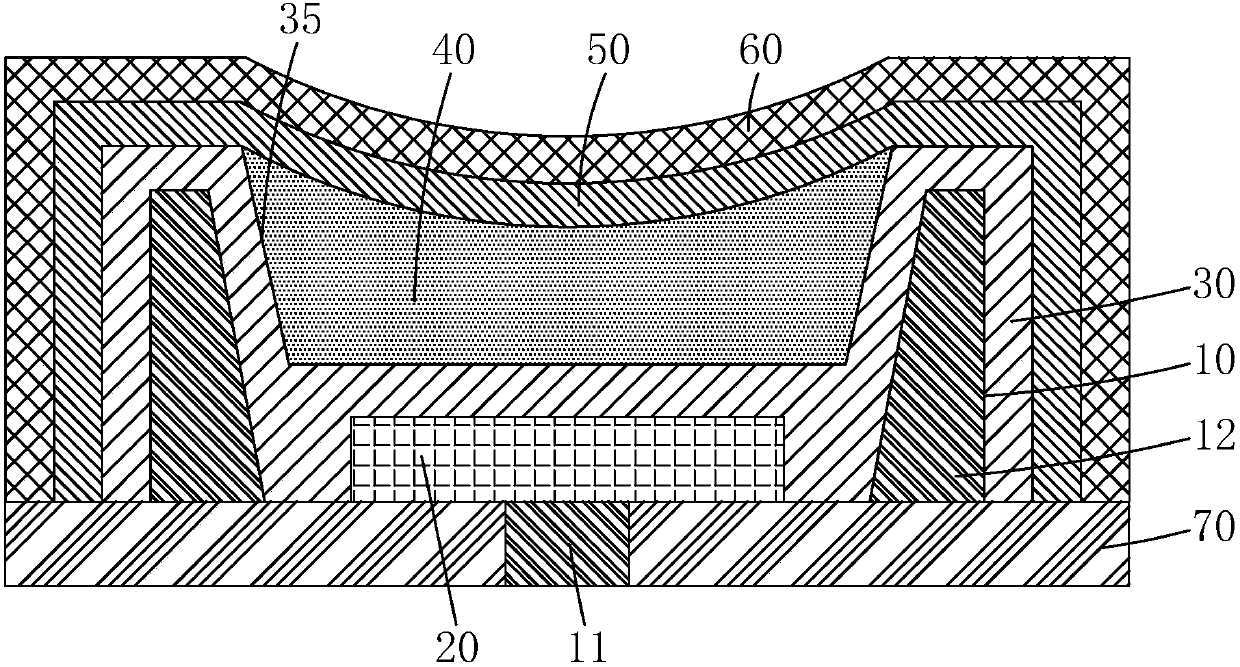

[0032] See image 3 , The present invention provides a quantum dot LED packaging structure, including:

[0033] The non-metal support 10 includes a bottom plate 11 and a side wall 12 connected to the periphery of the bottom plate 11;

[0034] The LED chip 20 is fixed on the bottom plate 11, and the thickness of the LED chip 20 is less than the height of the side wall 12;

[0035] The first barrier layer 30 covers the surface of the sidewall 12, the LED chip 20 and the bottom plate 11, and a groove 35 is formed on the surface of the first barrier layer 30 corresponding to the LED chip 20;

[0036] The quantum dot silica gel layer 40 is arranged in the groove 35;

[0037] The second barrier layer 50 covers the surfaces of the first barrier layer 30 and the quantum do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com