Unmanned intelligent filling and metering control method for PVC powder

A metering tube and powder technology, which is applied in the direction of weighing, measuring devices, electrical program control, etc., can solve the problems of difficulty in achieving the optimal state of product filling and metering control, high labor intensity, and hidden dangers of safety, and achieve benefits Ideal production, high degree of automation, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0059] The difference between Example 2 and Example 1 is: the weight after filling is set to B2 (38095 kg), and the net weight of the goods is calculated B3=B2-D=(32095 kg), when B3≥B1; when satisfying |B3 -B1 ∣>50 kg, overweight and unqualified, cannot print the factory goods list and settlement statement, and after the refilling measurement system 6 passes the processing, it will go through the weighbridge measurement final mining system 7, and then perform measurement verification 8;

Embodiment 3

[0060] The difference between Example 3 and Example 1 is: the weight after filling is set to B2 (37985 kg), and the net weight of the goods is calculated B3=B2-D=(31985 kg), when B3≤B1; when satisfying |B3 -B1 ∣≤50kg, qualified, can print the delivery list and settlement statement;

Embodiment 4

[0061] The difference between Example 4 and Example 1 is: the weight after filling is set to B2 (37935 kg), and the net weight of the goods is calculated B3=B2-D=(31935 kg), when B3≤B1; when satisfying |B3 -B1 ∣>50 kg, overweight and unqualified, cannot print the factory goods list and settlement statement, and after the refilling measurement system 6 passes the processing, it will go through the weighbridge measurement final mining system 7, and then perform measurement verification 8;

[0062] All the above processes are compiled and logically controlled by an automatic control system.

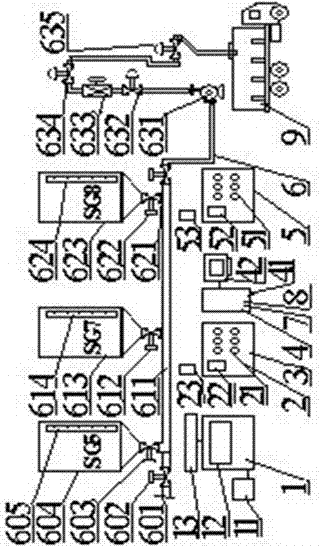

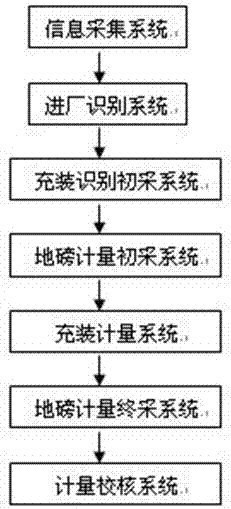

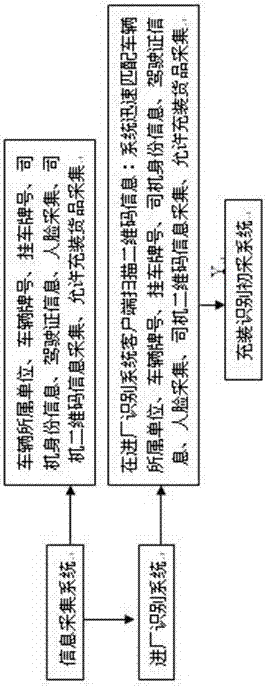

[0063] An unattended intelligent filling measurement control method for PVC powder as described above, wherein an incoming identification system 2, a filling identification initial mining system 3, and a weighbridge metering initial mining system 4 are installed at the factory entrance; mining system 4; weighbridge metering initial mining system 4; filling identification final mining system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com