Method for changing heating temperature in electric heating membrane region, and miniature electric heating piece produced by utilizing same

A technology of area heating and electric heaters, which is applied in the direction of ohmic resistance heating, ohmic resistance heating parts, electric heating devices, etc., can solve the problems of complicated processing technology and unsuitable heating sheets, and achieve simple processing technology, fast heating speed, and high-quality workmanship. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

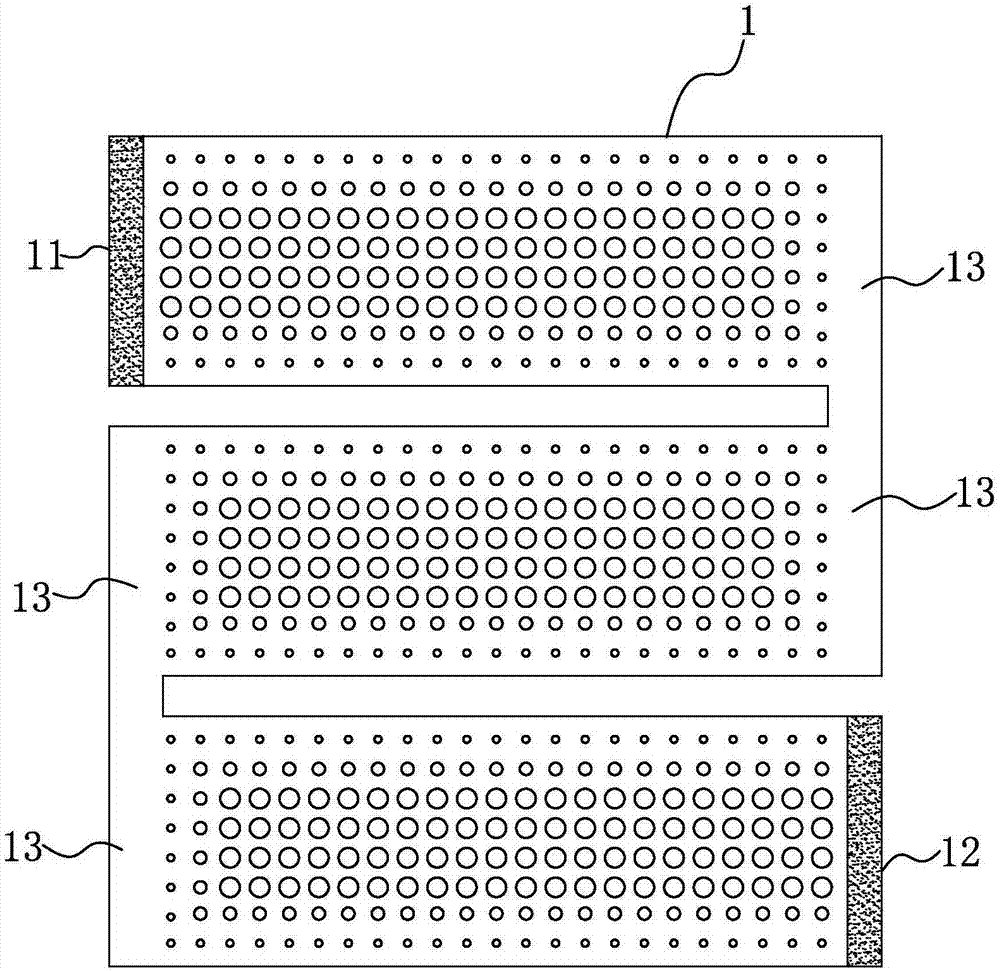

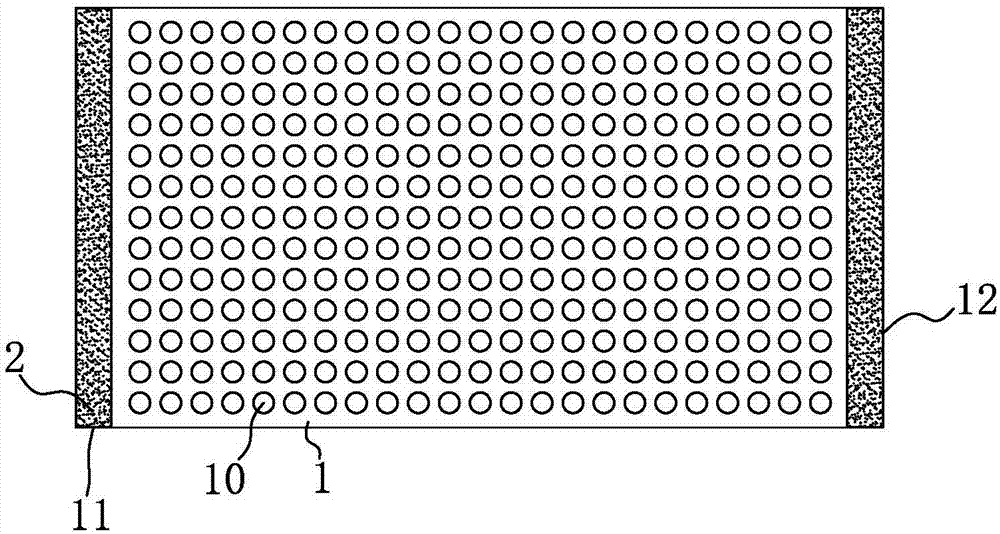

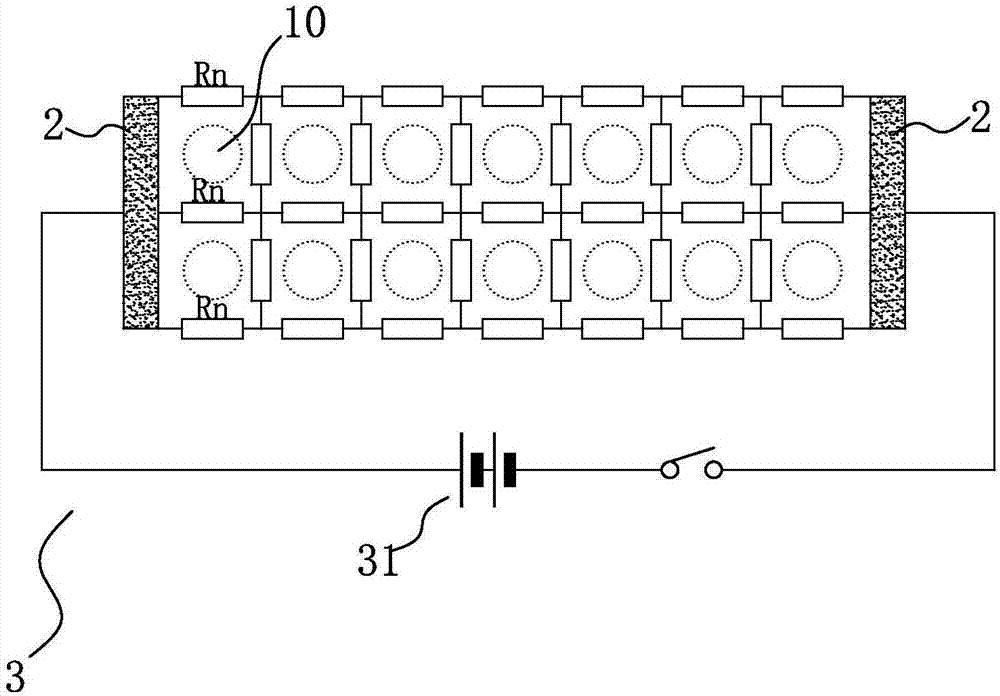

[0024] The present invention is a kind of miniature electric heater, see figure 1 As shown, this is the first embodiment of the present invention. In this embodiment, the miniature heater includes: a thin sheet 1 made of conductive material. In the first embodiment, the sheet 1 can be made of a high-resistance alloy material, such as a nickel-chromium alloy material. Of course, other conductive and heating sheets can also be used.

[0025] Electrode areas 11 and 12 are provided at the beginning and end of the sheet 1, through which the sheet is connected to a circuit to generate heat, and the area between the electrode areas 11 and 12 of the sheet 1 is provided with a Through holes 10 distributed in an array. The through hole 10 is formed by direct punching, or laser cutting, or chemical etching.

[0026] According to different materials, the thickness of the sheet 1 is 0.1-1 mm, and the diameter of the through hole 10 is 0.1-5 mm.

[0027] See figure 2 As shown, this is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com