Integrated flue gas purification system

A flue gas purification and flue gas technology, which is applied in the control/regulation system, the use of liquid separation agents, chemical instruments and methods, etc., can solve the problems that flue gas purification equipment cannot achieve flue gas cooling, and achieve improved water washing efficiency and dust removal Desulfurization effect, low cost, reasonable arrangement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

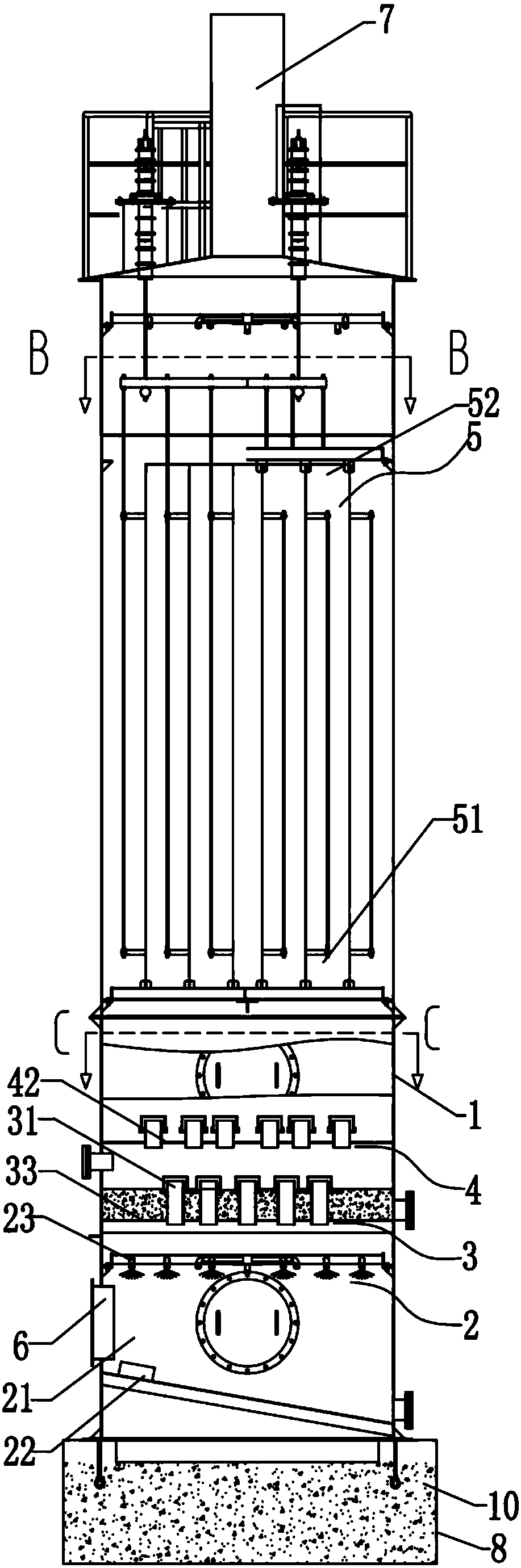

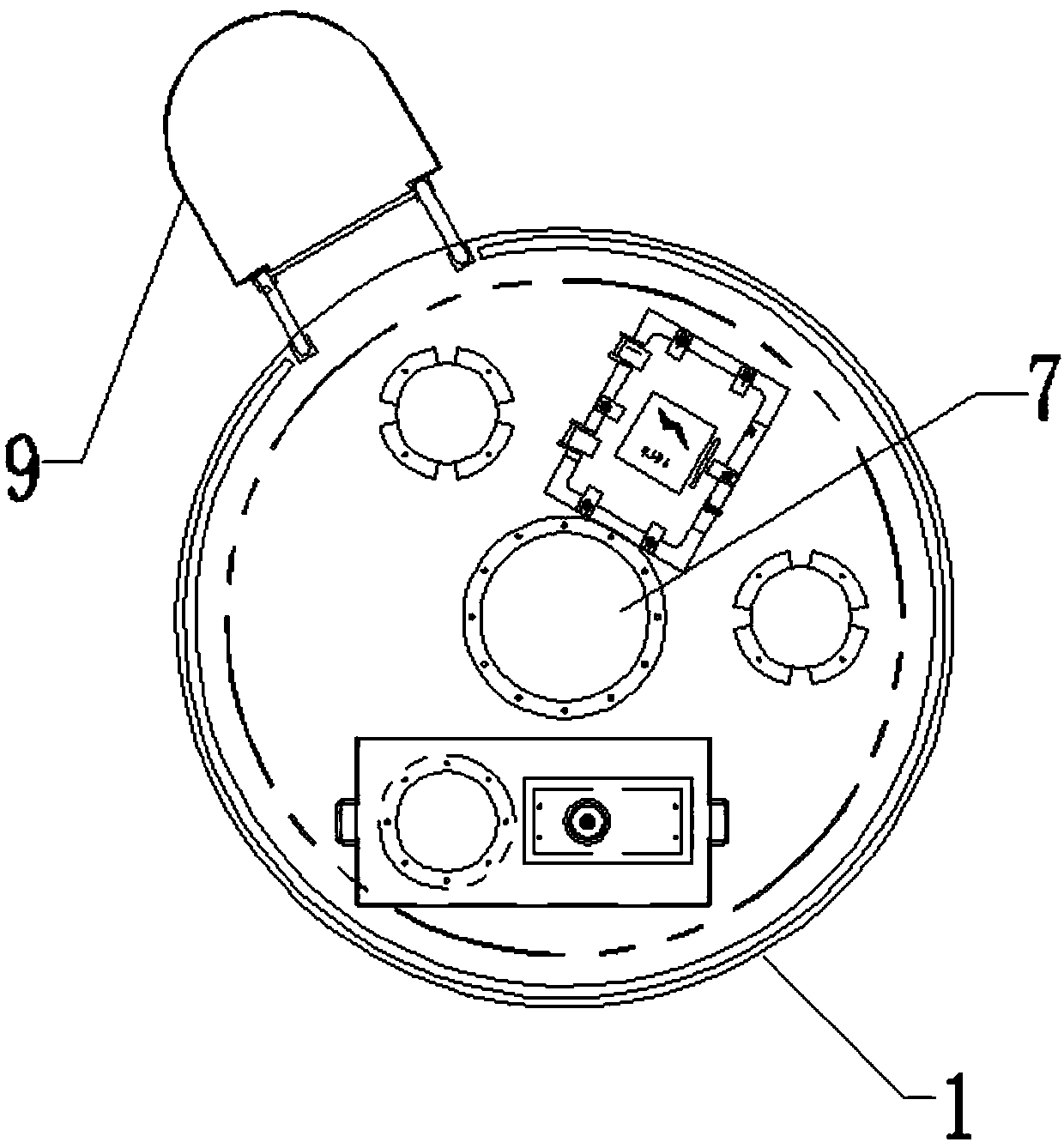

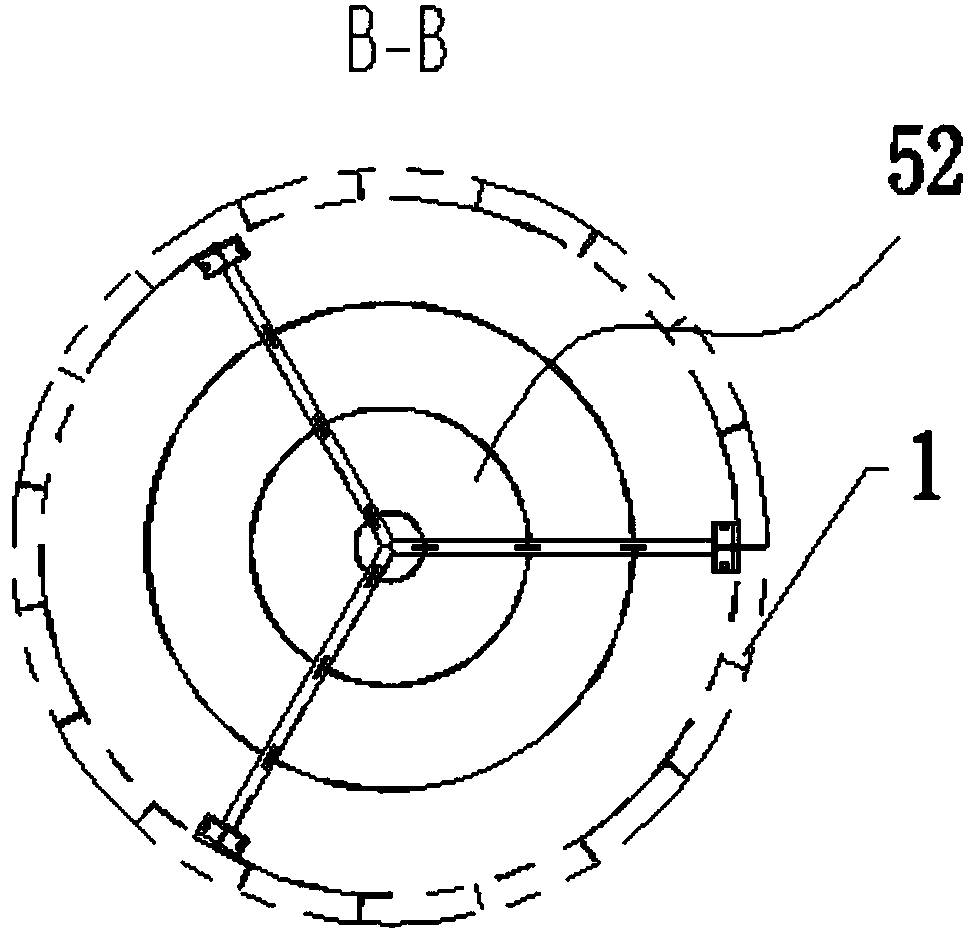

[0044] see Figure 1 to Figure 15, the present invention is achieved in this way: an integrated flue gas purification system, the system includes a smoke tower 1, a spray device 2, a water washing device 3, a demisting device 4 and an electric dust removal device 5, the spray device 2 , water washing device 3, demisting device 4 and electrostatic precipitator 5 are sequentially arranged inside the smoke tower 1 from bottom to top, and the system also includes a smoke inlet channel 6 and a smoke outlet channel 7, the smoke inlet channel 6, smoke outlet channel The channels 7 are all connected with the inside of the smoke tower 1, and the flue gas enters the inside of the smoke tower 1 from the smoke inlet channel 6 and flows through the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com