High-power laser welding system and method based on high-speed scanning galvanometer

A laser welding and high-speed scanning technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of aluminum alloy welding explosion points, welding cracks, etc., and achieve stable welding width, increase contact area, and shape regularity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

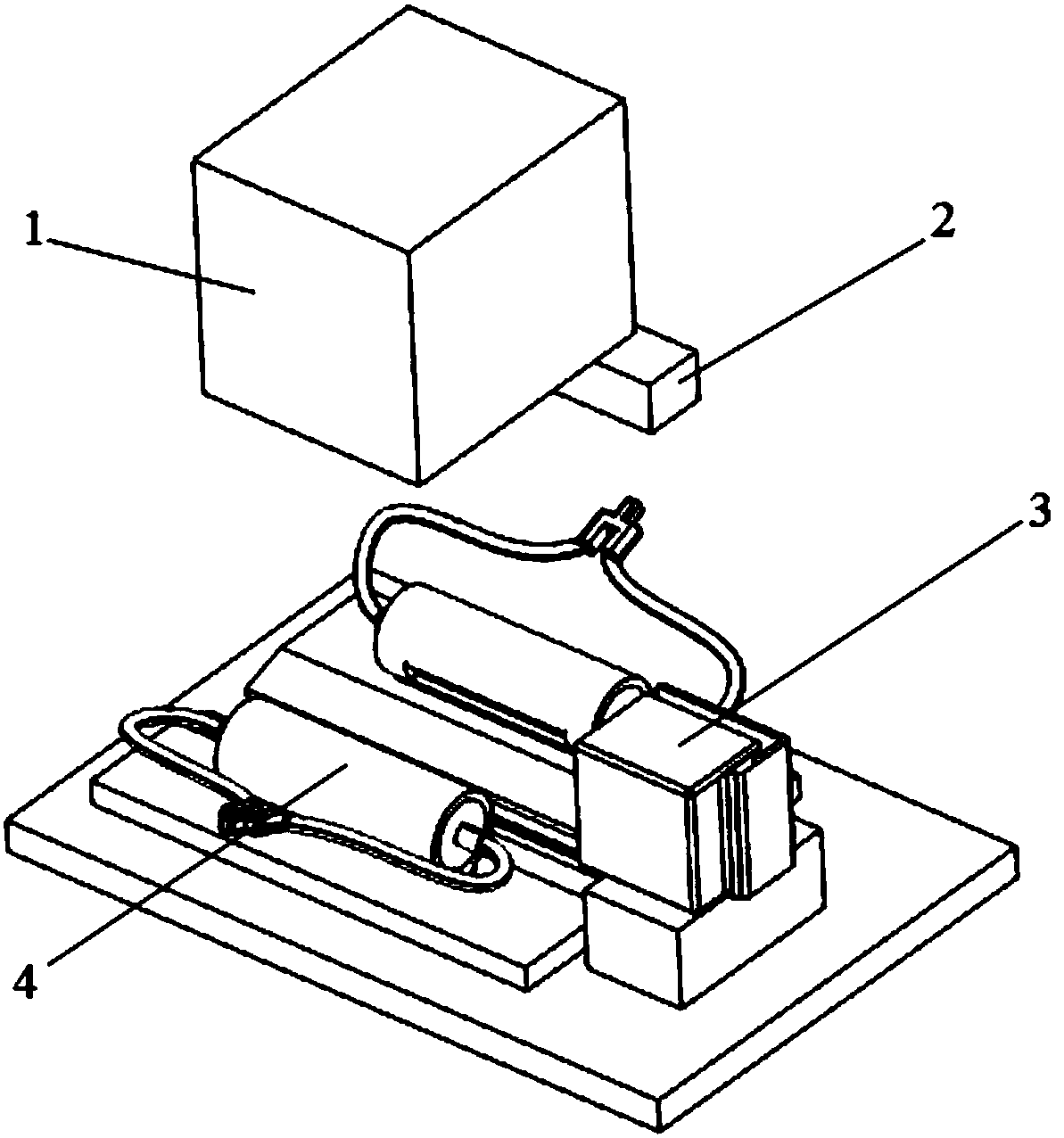

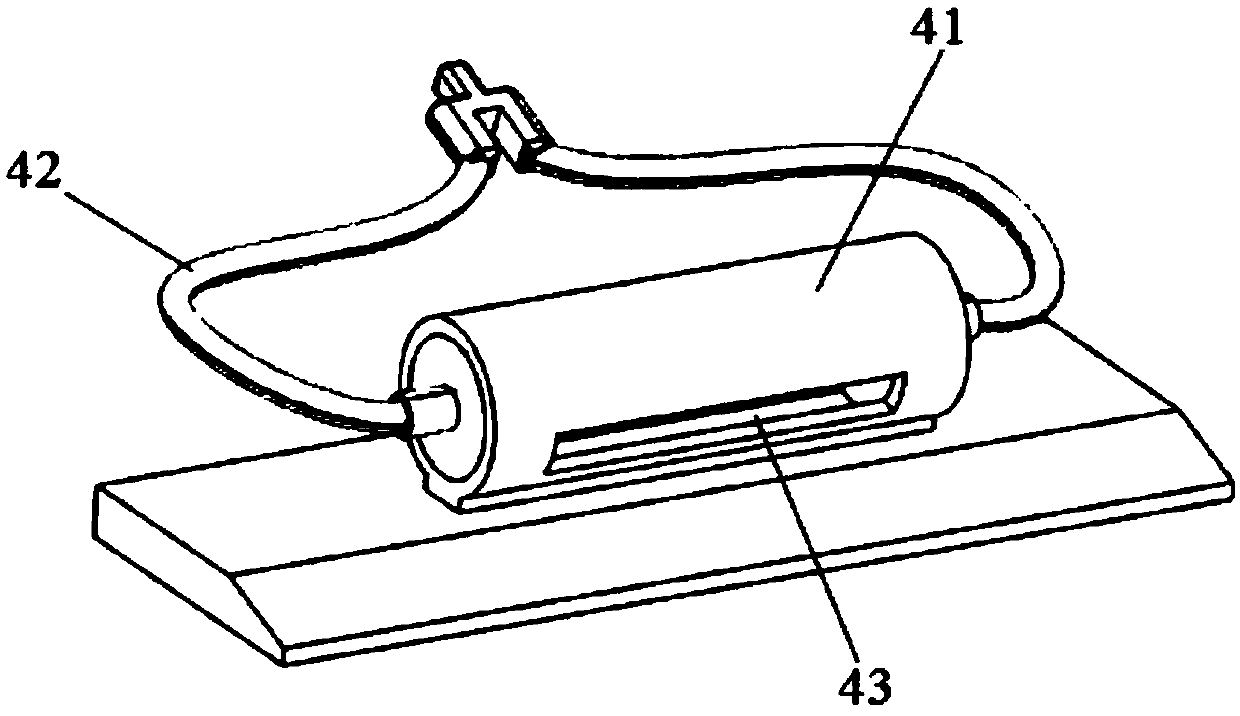

[0037] Please refer to Figure 1-Figure 2 , this embodiment is a high-power laser welding system based on a high-speed scanning galvanometer, which includes a manipulator (not shown in the figure), a laser welding mechanism 1 fixed at the movable end of the manipulator, and a high-position shielding air knife located below the laser welding mechanism 1 2. The low shielding gas knife 3 located below the high shielding gas knife 2 and above the position to be welded and the gas shielding device 4 blowing from both sides of the position to be welded.

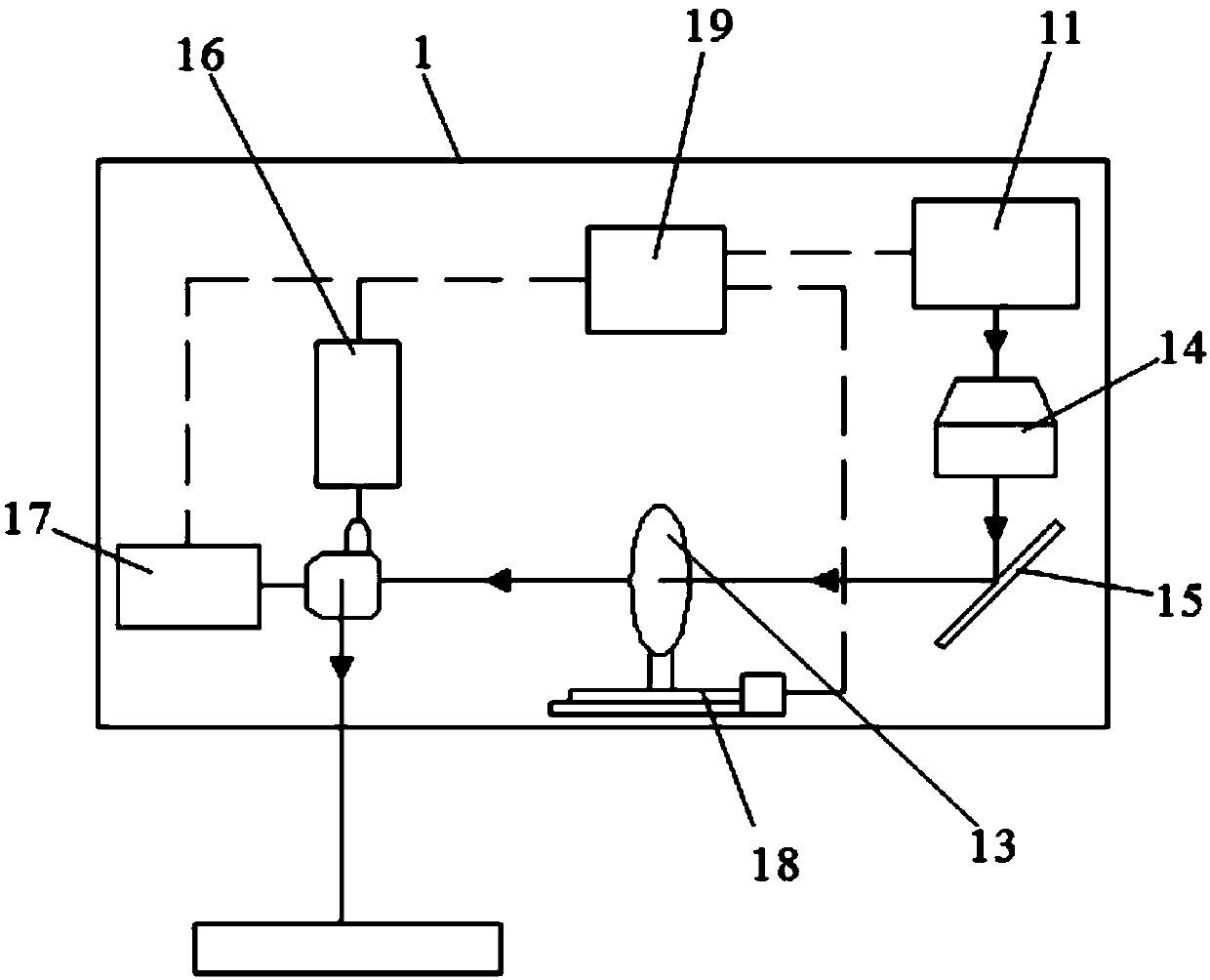

[0038] The laser welding mechanism 1 includes a laser 11, a collimating mirror 14, a 45° total reflection mirror 15, a focusing mirror 13 moving along the direction of the laser beam, an X-axis scanning galvanometer 16, and a Y-axis scanning galvanometer 17 according to the beam transmission direction. 1. A Z-axis driving mechanism 18 and a control device 19 for driving the focusing mirror 13 to move. The control device 19 is elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com