A method of temperature measurement after the blast furnace air temperature couple is damaged

An air temperature and galvanic couple technology is applied in the field of temperature measurement after the blast furnace air temperature galvanic couple is damaged, which can solve problems such as affecting normal production, and achieve the effects of smooth and fast insertion, convenient and fast installation and welding, and guaranteed accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

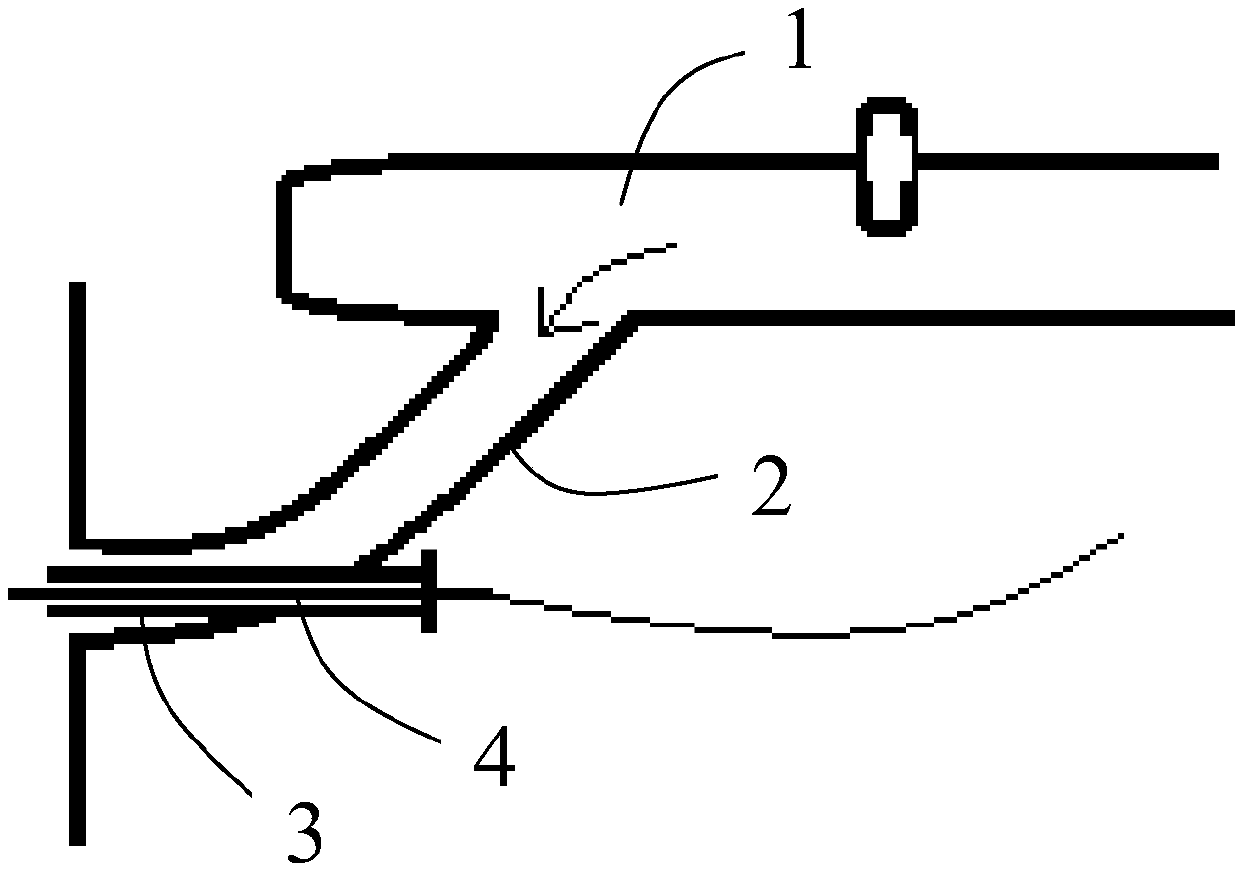

[0037] The temperature measuring method after the blast furnace air temperature couple of the present embodiment is damaged includes the following specific steps:

[0038] Step S101, select the coal injection gun 3 used in the blast furnace closest to the hot blast main pipe 1, pull out the coal injection gun 3 and cut off the tail flange of the coal injection gun 3, cut the tail port of the coal injection gun 3 flat, and then clean the coal injection gun 3 The deposits inside and outside are polished with sand to make the inner wall of the coal injection gun 3 smooth. Since the blast furnace has multiple coal injection guns 3, taking out one of them will not affect the blast furnace. In addition, the coal injection gun 3 and the coal gun road Unfixed seal, easy to pull out;

[0039] Step S102, select a hollow screw whose size matches the installation size of the thermocouple 4, and weld the hollow screw concentrically to the coal injection gun 3 with the tail flange cut off, ...

Embodiment 2

[0046] The temperature measurement method of the blast furnace air temperature couple damaged in this embodiment, the steps are basically the same as in Example 1, and the present invention is applied to actual production. When the two air temperature couples are all damaged, first measure the hot blast main pipe 1 to measure The actual pipeline distance L between the point and the insertion point of the coal injection gun 3, for example L=1.9m, when t=1010°C, the air temperature of the hot blast main pipe T=t+1.9*55=1114.5°C.

[0047] In contrast, when the two air temperature couples are all in good condition, the air temperature of the hot air main pipe is T = 1121°C, and the error of the two data is 0.59%, which meets the production requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com