Fruity flavor composite particles and preparation method and application thereof

A composite particle and flavor technology, which is applied in the application, tobacco, e-liquid filter and other directions, can solve the problems of the auxiliary effect of difficult spices or odor-absorbing materials, the difficulty of using spices and odor-absorbing materials, and the limited amount of spices added, so as to achieve biological preservation. Active, retain nutrients, increase the effect of volume sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

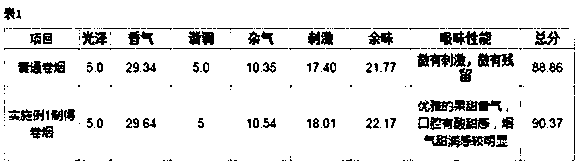

Embodiment 1

[0030] A fruit flavor compound granule, the preparation method steps of the granule are as follows:

[0031] (1) Material preparation: Prepare the mixed material according to the following components by mass:

[0032] 45 parts by mass of dried tangerine peel, 15 parts by mass of dried green apple, 10 parts by mass of dried lemon, 15 parts by mass of dried kiwifruit, 2 parts by mass of neomethylhesperidin dihydrochalcone, 1 part by mass of ketone, 1 part by mass of nicotine, 0.5 parts by mass of malic acid, 2 parts by mass of citric acid, and 8.5 parts by mass of the binder made of carboxymethyl cellulose;

[0033] (2) Superfine pulverization: Use a low-temperature ultrafine pulverizer to superfine the mixed material described in step (1) to make it into a powdery material. The powdery material passes through a 160-mesh sieve. During the pulverization process, Control the temperature of the circulating cooling water of the pulverizer at 25°C;

[0034] (3) Mixing: Pour the obt...

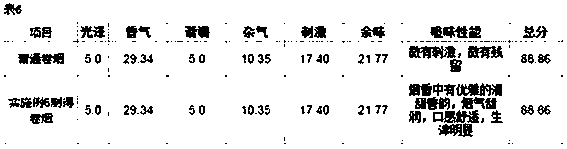

Embodiment 2

[0043] A fruit flavor compound granule, the steps of the preparation method of the compound granule are as follows:

[0044] (1) Material preparation: Prepare the mixed material according to the following mass percentage components:

[0045] 39 parts by mass of dried tangerine peel, 20 parts by mass of dried green apple, 8 parts by mass of dried lemon, 12 parts by mass of dried kiwifruit, 5 parts by mass of neomethylhesperidin dihydrochalcone, and 5 parts by mass of covered 3 parts by mass of ketone, 2 parts by mass of nicotine, 0.1 parts by mass of malic acid, 0.9 parts by mass of citric acid, and 10 parts by mass of adhesive made of hydroxypropyl methylcellulose;

[0046] (2) Superfine pulverization: Use a low-temperature ultrafine pulverizer to superfine the mixed material described in step (1) to make it into a powdery material. The powdery material passes through a 160-mesh sieve. During the pulverization process, Control the temperature of the circulating cooling water ...

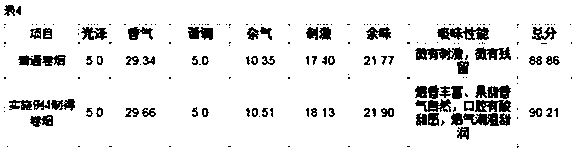

Embodiment 3

[0056] A fruit flavor compound granule, the steps of the preparation method of the compound granule are as follows:

[0057] (1) Material preparation: Prepare the mixed material according to the following mass percentage components:

[0058] 30 parts by mass of dried tangerine peel, 20 parts by mass of dried green apple, 10 parts by mass of dried lemon, 15 parts by mass of dried kiwifruit, 5 parts by mass of neomethylhesperidin dihydrochalcone, 5 parts by mass of ketone, 2 parts by mass of nicotinone, 1 part by mass of malic acid, 2 parts by mass of citric acid, and 10 parts by mass of xanthan gum as the adhesive;

[0059] (2) Superfine pulverization: Use a low-temperature ultrafine pulverizer to superfine the mixed material described in step (1) to make it into a powdery material. The powdery material passes through a 160-mesh sieve. During the pulverization process, Control the temperature of the circulating cooling water of the pulverizer at 35°C;

[0060] (3) Mixing: Pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com