A method for harmlessly treating barium slag by using phosphogypsum

A technology of harmless treatment and phosphogypsum, applied in the direction of solid waste removal, etc., can solve the problems of manganese slag not being common enough, high cost, poor neutralization effect, etc., and achieve the effects of low cost, reduced concentration and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

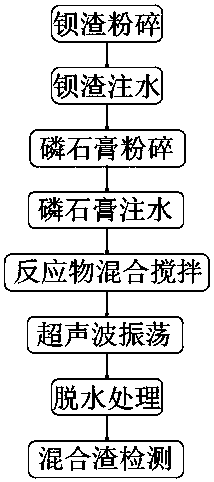

Image

Examples

Embodiment 1

[0022] A method for harmlessly treating barium slag with phosphogypsum, comprising the following steps: S1) crushing barium slag: putting the barium slag into a grinder to obtain barium slag with a mesh number of 50.

[0023] S2) Water injection into the barium slag: inject water into the ground barium slag in S1), so that the water content of the ground barium slag is 15.0%.

[0024] S3) Grinding of phosphogypsum: Putting phosphogypsum into a grinder to obtain phosphogypsum with a mesh number of 50.

[0025] S4) Phosphogypsum water injection: inject water into the ground phosphogypsum in S3), so that the water content of the ground phosphogypsum is 4.2%.

[0026] S5) Mixing and stirring of the reactants: Put the barium slag after water injection and the phosphogypsum after water injection into the mixer according to the mass ratio of 10.0:1.0, and the mixer works for 20 minutes.

[0027] S6) Ultrasonic vibration: After the mixer stops working, put the ultrasonic vibrating ro...

Embodiment 2

[0033] A method for harmlessly treating barium slag with phosphogypsum, comprising the following steps: S1) crushing barium slag: putting the barium slag into a grinder to obtain barium slag with a mesh number of 50.

[0034] S2) Water injection into the barium slag: inject water into the ground barium slag in S1), so that the water content of the ground barium slag is 15.9%.

[0035] S3) Grinding of phosphogypsum: Putting phosphogypsum into a grinder to obtain phosphogypsum with a mesh number of 50.

[0036] S4) Phosphogypsum water injection: inject water into the ground phosphogypsum in S3), so that the water content of the ground phosphogypsum is 3.8%.

[0037] S5) Mixing and stirring of the reactants: Put the barium slag after water injection and the phosphogypsum after water injection into the mixer according to the mass ratio of 10.0:5.0, and the mixer works for 20 minutes.

[0038] S6) Ultrasonic vibration: After the mixer stops working, put the ultrasonic vibrating ro...

Embodiment 3

[0044] A method for harmlessly treating barium slag with phosphogypsum, comprising the following steps: S1) crushing barium slag: putting the barium slag into a grinder to obtain barium slag with a mesh number of 50.

[0045] S2) Water injection into the barium slag: inject water into the ground barium slag in S1), so that the water content of the ground barium slag is 16.0%.

[0046] S3) Grinding of phosphogypsum: Putting phosphogypsum into a grinder to obtain phosphogypsum with a mesh number of 50.

[0047] S4) Phosphogypsum water injection: inject water into the ground phosphogypsum in S3), so that the water content of the ground phosphogypsum is 3.5%.

[0048] S5) Mixing and stirring of the reactants: Put the barium slag after water injection and the phosphogypsum after water injection into the mixer according to the mass ratio of 10.0:15.0, and the mixer works for 20 minutes.

[0049] S6) Ultrasonic vibration: After the mixer stops working, put the ultrasonic vibrating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com