V-type gas stripping nitrogen and phosphorus removal process for large and medium-sized sewage treatment

A sewage treatment, denitrification and phosphorus removal technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of large and medium-sized sewage denitrification and removal The actual needs of phosphorus production, the inability to carry out large-scale sewage treatment, and the difficulty of stably meeting the discharge water quality standards have achieved the effects of small footprint, construction investment saving, and short treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

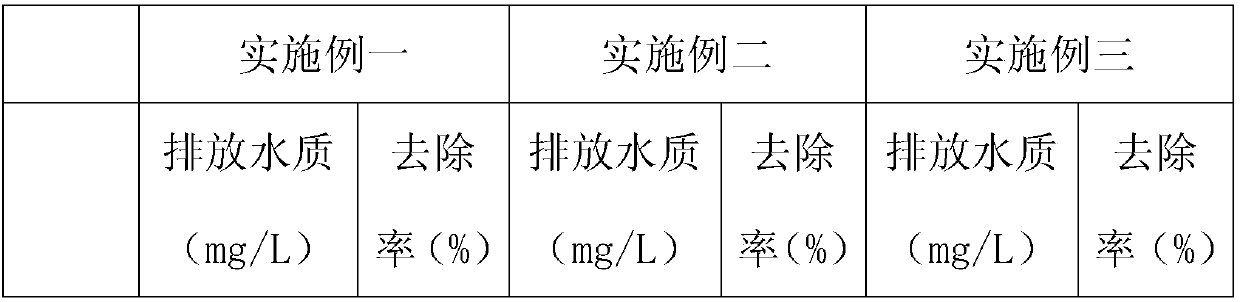

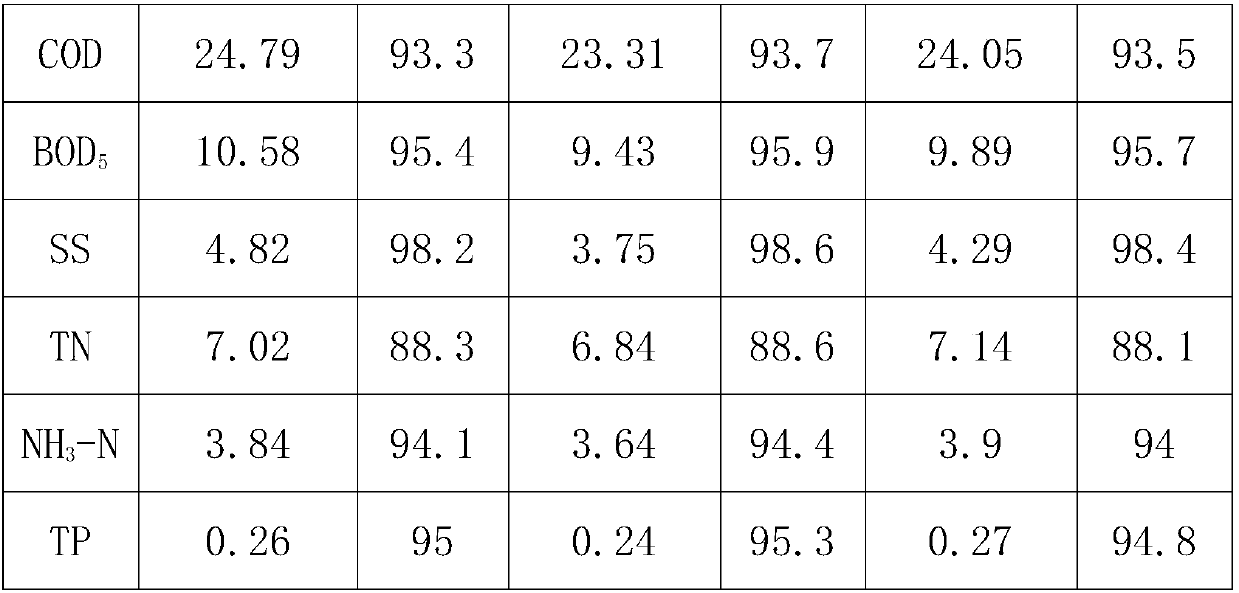

Embodiment 1

[0022] The V-type gas stripping denitrification and phosphorus removal process for large and medium-sized sewage treatment proposed by the present invention comprises the following steps:

[0023] S1. Using the existing technical facilities, the sewage is pretreated through the coarse grid room, the sewage lifting pump room, the fine grid room and the swirl grit chamber in sequence, and the separated sewage flows into the V-shaped integrated gas lift tank , the V-type air-lifting integrated tank is divided into three zones: anaerobic, anoxic and aerobic, in which the anaerobic zone is located in the center of the V-shaped integrated gas-lifting tank, and the anoxic zone is located on one side of the anaerobic zone. The aerobic zone is surrounded by the anaerobic zone and the anoxic zone. After the sewage flows into the aerobic zone and anaerobic zone respectively, it flows into the anoxic zone through the aerobic zone and the anaerobic zone, and the separated sludge is introduc...

Embodiment 2

[0029]The V-type gas stripping denitrification and phosphorus removal process for large and medium-sized sewage treatment proposed by the present invention comprises the following steps:

[0030] S1. Using the existing technical facilities, the sewage is pretreated through the coarse grid room, the sewage lifting pump room, the fine grid room and the swirl grit chamber in sequence, and the separated sewage flows into the V-shaped integrated gas lift tank , the V-type air-lifting integrated tank is divided into three zones: anaerobic, anoxic and aerobic, in which the anaerobic zone is located in the center of the V-shaped integrated gas-lifting tank, and the anoxic zone is located on one side of the anaerobic zone. The aerobic zone is surrounded by the anaerobic zone and the anoxic zone. After the sewage flows into the aerobic zone and anaerobic zone respectively, it flows into the anoxic zone through the aerobic zone and the anaerobic zone, and the separated sludge is introduce...

Embodiment 3

[0036] The V-type gas stripping denitrification and phosphorus removal process for large and medium-sized sewage treatment proposed by the present invention comprises the following steps:

[0037] S1. Using the existing technical facilities, the sewage is pretreated through the coarse grid room, the sewage lifting pump room, the fine grid room and the swirl grit chamber in sequence, and the separated sewage flows into the V-shaped integrated gas lift tank , the V-type air-lifting integrated tank is divided into three zones: anaerobic, anoxic and aerobic, in which the anaerobic zone is located in the center of the V-shaped integrated gas-lifting tank, and the anoxic zone is located on one side of the anaerobic zone. The aerobic zone is surrounded by the anaerobic zone and the anoxic zone. After the sewage flows into the aerobic zone and anaerobic zone respectively, it flows into the anoxic zone through the aerobic zone and the anaerobic zone, and the separated sludge is introduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com