Polysulfone and biphenyl type sulfonated polyether sulfone as well as preparation method and application thereof

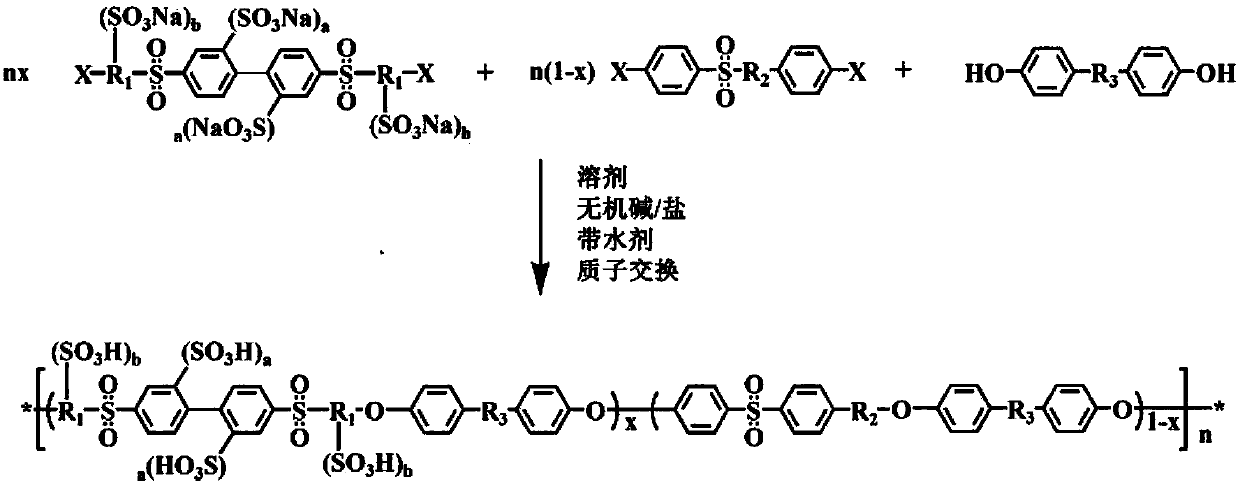

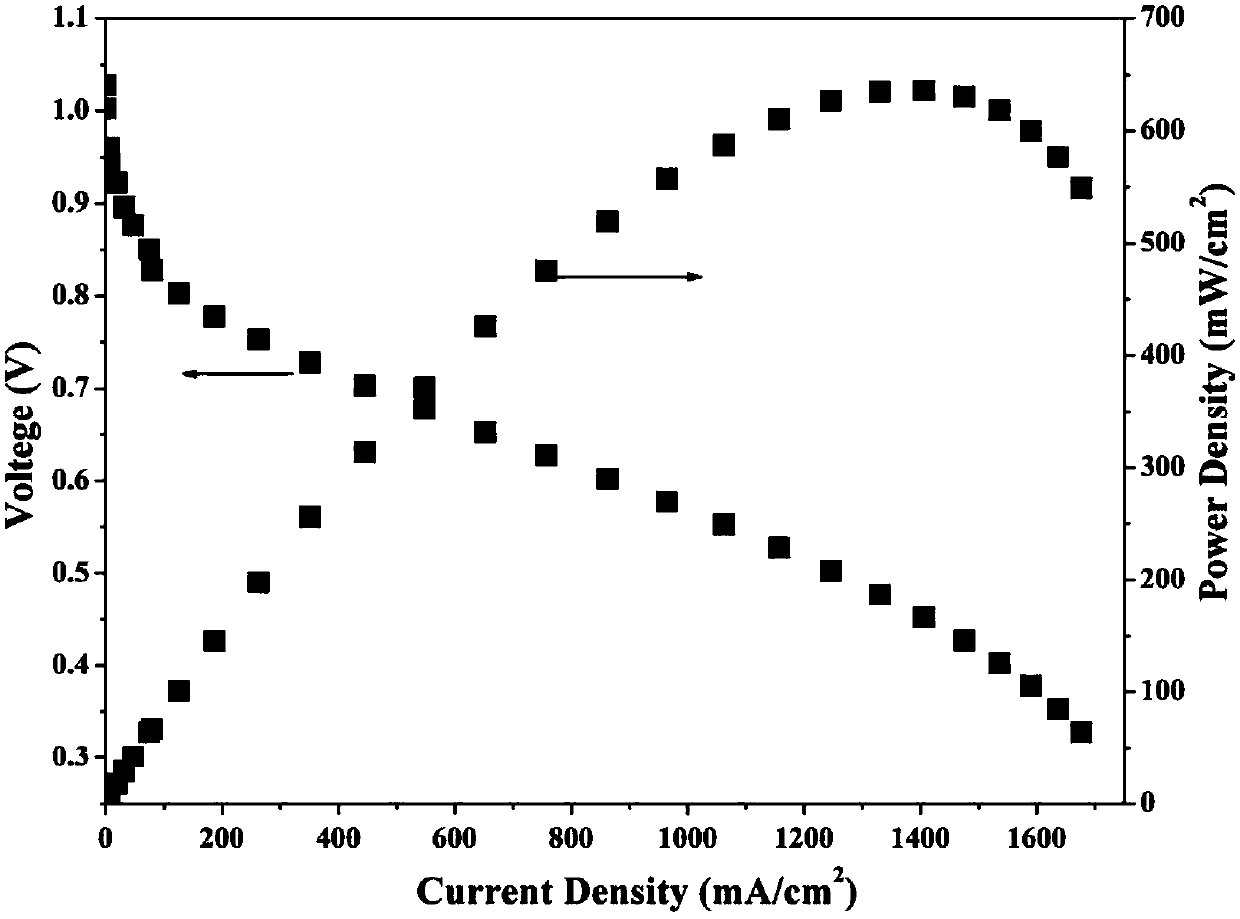

A technology of sulfonated polyethersulfone and sulfone-based biphenyl, which is applied in electrochemical generators, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as limited applications, achieve improved conductivity, and simple preparation process , The effect that the reaction conditions are easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

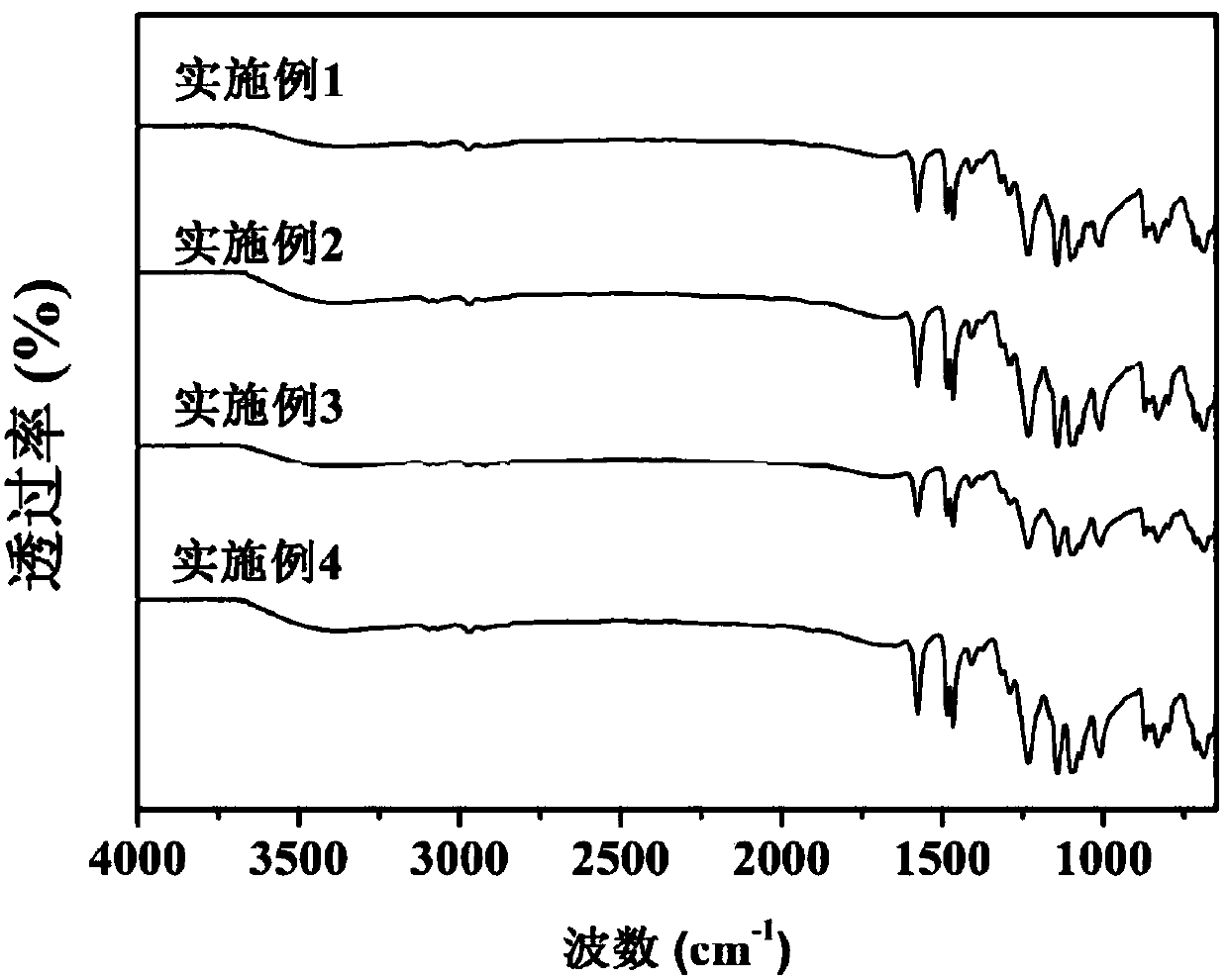

[0037] Example 1: Synthesis of polysulfone-based biphenyl type sulfonated polyethersulfone homopolymer Al and preparation of proton exchange membrane

[0038]Under nitrogen protection and mechanical stirring, add 13.48g (20mmol) of 4,4'-bis(4-fluorobenzenesulfonyl-3-sulfonate)biphenyl to a 250mL dry three-neck flask with a water separator , 3.72g (20mmol) of 4,4'-diphenol and 55-85mL of N,N-dimethylacetamide, preferably, the optimal addition amount of this embodiment is 75mL. After the solid is completely dissolved, add 5.52-6.90g (40-50mmol) of potassium carbonate and 10-20mL of toluene. Preferably, the optimal addition amounts in this embodiment are 5.80g (42mmol) and 14mL respectively. After stirring evenly, raise the temperature of the reaction system to 120-140°C for 2-6 hours, distill off the water generated in the reaction, and then raise the temperature to 150-170°C for 8-24 hours, preferably, the two best ones in this example The temperature points are 120°C and 160°...

Embodiment 2

[0040] Example 2: Synthesis of polysulfone-based biphenyl type sulfonated polyethersulfone copolymer B-3 / 1 / 2 and preparation of proton exchange membrane

[0041] Under nitrogen protection and mechanical stirring, add 4,4'-bis(4-fluorobenzenesulfonyl-3-sulfonate sodium)biphenyl-2,2' into a 250mL dry three-necked flask with a water separator - 5.27g (6mmol) of sodium disulfonate, 3.04g (12mmol) of 4,4'-difluorodiphenyl sulfone, 3.34g (18mmol) of 4,4'-diphenol, and N,N-dimethylacetamide 40-60mL, preferably, the optimal addition amount in this embodiment is 50mL respectively. After the solid is completely dissolved, add 4.97-6.21g (36-45mmol) of potassium carbonate and 10-20mL of toluene. Preferably, the optimal addition amounts in this embodiment are 5.24g (38mmol) and 10mL respectively. After stirring evenly, raise the temperature of the reaction system to 120-140°C for 2-6 hours, distill off the water generated in the reaction, and then raise the temperature to 150-170°C for 8...

Embodiment 3

[0043] Example 3: Synthesis of polysulfone-based biphenyl type sulfonated polyethersulfone copolymer C-3 / 2 / 1 and preparation of proton exchange membrane

[0044] Under nitrogen protection and mechanical stirring, add 8.09 g (12 mmol) of 4,4'-bis(4-fluorobenzenesulfonyl-3-sulfonate) biphenyl to a 250 mL dry three-neck flask with a water separator , 4,4'-bis(4-fluorobenzenesulfonyl)biphenyl 2.82g (6mmol), 2,2'-bis(4-hydroxyphenyl)propane 4.10g (18mmol) and 1-methylpyrrolidone 50- 75mL, preferably, the optimal addition amount of this embodiment is respectively 60mL. After the solid is completely dissolved, add 2.02-2.52g (36-45mmol) of potassium hydroxide and 10-20mL of xylene. Preferably, the optimal addition amounts in this embodiment are 2.35g (42mmol) and 15mL respectively. After stirring evenly, raise the temperature of the reaction system to 120-140°C for 2-6 hours, distill off the water generated in the reaction, and then raise the temperature to 150-170°C for 8-24 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com