Composite film for fuselage and its preparation method and application

A composite film and fuselage technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve problems such as poor adhesion of the rear cover film, achieve high peel strength, not easy to fade, reduce shielding effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

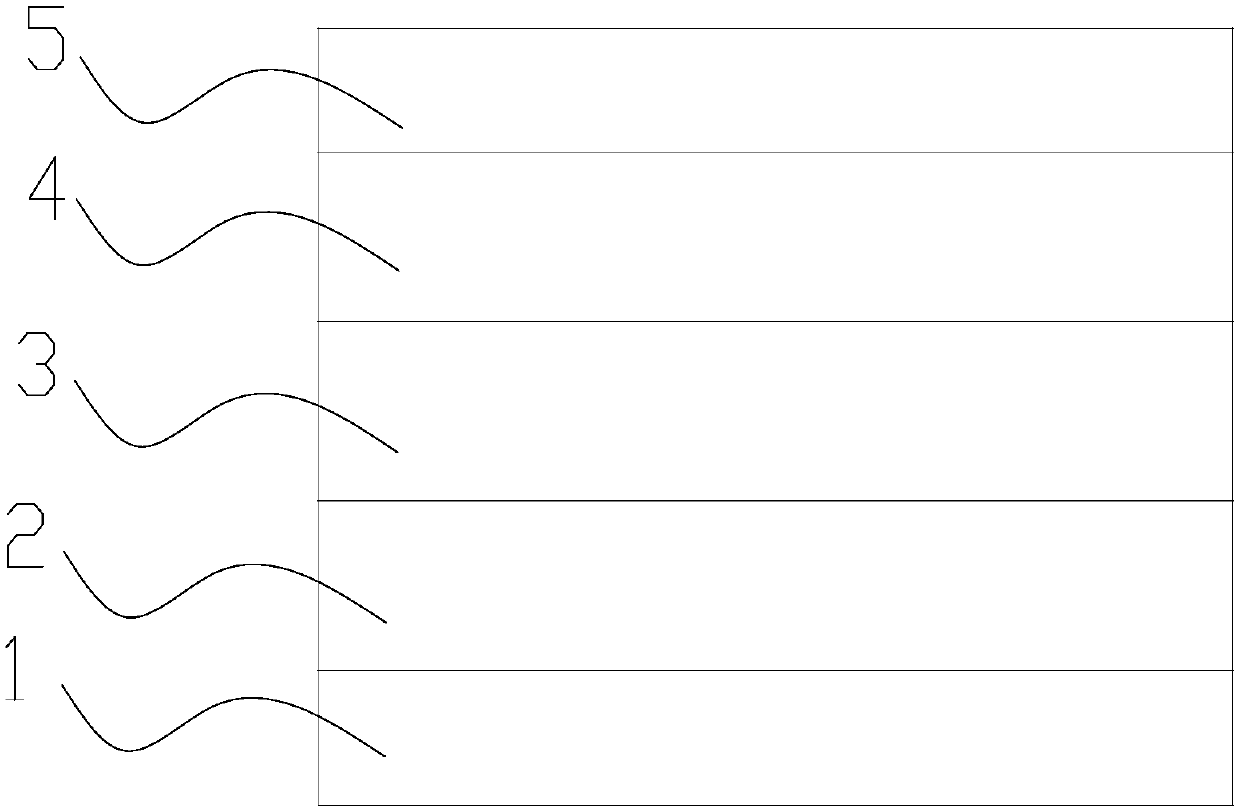

Image

Examples

Embodiment 1

[0045] A composite film for a fuselage, comprising a glass substrate and a first Cr layer, a TiO 2 layer, the second Cr layer and SiO 2 layer.

[0046] The preparation method of the fuselage composite film comprises:

[0047] 1) Substrate pretreatment steps: take the glass substrate, ultrasonically clean it with acetone, absolute ethanol and deionized water in sequence, and dry it with high-purity nitrogen;

[0048] 2) Pre-melting treatment steps: for Cr film material, TiO 2 Membranes and SiO 2 The film material is pre-melted, the pre-melting current is 160A, and the pre-melting time is 3 minutes;

[0049] 3) The step of depositing the first Cr layer: take the Cr film material after the treatment in step 2), and use the electron beam evaporation coating method to coat and deposit the first Cr layer on the surface of the glass substrate after the treatment in step 1), and the coating parameters are: vacuum degree 3.0×10 -5 Torr, the heating current of Cr film material is ...

Embodiment 2

[0059] A composite film for a fuselage, comprising a glass substrate and a first Cr layer, a TiO 2 layer, the second Cr layer and SiO 2 layer.

[0060] The preparation method of the fuselage composite film comprises:

[0061] 1) Substrate pretreatment steps: take the glass substrate, ultrasonically clean it with acetone, absolute ethanol and deionized water in sequence, and dry it with high-purity nitrogen;

[0062] 2) Pre-melting treatment steps: for Cr film material, TiO 2 Membranes and SiO 2 The film material is pre-melted, the pre-melting current is 160A, and the pre-melting time is 3 minutes;

[0063] 3) The step of depositing the first Cr layer: take the Cr film material after the treatment in step 2), and use the electron beam evaporation coating method to coat and deposit the first Cr layer on the surface of the glass substrate after the treatment in step 1), and the coating parameters are: vacuum degree 3.0×10 -5 Torr, the heating current of Cr film material is ...

Embodiment 3

[0073] A composite film for a fuselage, comprising a glass substrate and a first Cr layer, a TiO 2 layer, the second Cr layer and SiO 2 layer.

[0074] The preparation method of the fuselage composite film comprises:

[0075] 1) Substrate pretreatment steps: take the glass substrate, ultrasonically clean it with acetone, absolute ethanol and deionized water in sequence, and dry it with high-purity nitrogen;

[0076] 2) Pre-melting treatment steps: for Cr film material, TiO 2 Membranes and SiO 2 The film material is pre-melted, the pre-melting current is 160A, and the pre-melting time is 3 minutes;

[0077] 3) The step of depositing the first Cr layer: take the Cr film material after the treatment in step 2), and use the electron beam evaporation coating method to coat and deposit the first Cr layer on the surface of the glass substrate after the treatment in step 1), and the coating parameters are: vacuum degree 3.0×10 -5 Torr, the heating current of Cr film material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com