Composite nanometer oxygen sensing material capable of performing efficiently energy transfer, preparation method and applications thereof

An energy transfer and oxygen sensing technology, applied in the field of composite nano-oxygen sensing materials, can solve the problems of weak detection fluorescence and low sensitivity, and achieve the effect of improving sensitivity and great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Composite nano-oxygen sensing material (Fe 3 o 4 @PtTFPP / C6@silane) Preparation

[0026] (1) Iron ferric oxide nanoparticles were synthesized according to the co-precipitation method. In order to increase its stability, the surface was coated with oleic acid (Wang, J., et al. Remote manipulation of micronomachines containing magnetic nanoparticles. Optics Letters 34,581 -583 (2009)).

[0027] (2) The prepared oily iron ferric oxide nanoparticles are formulated into 5 mg / mL tetrahydrofuran solution, n-octyltrimethoxysilane (purchased from sigma company) is formulated into 7.5 mg / mL tetrahydrofuran solution, platinum ( Ⅱ) MESO-tetrakis(pentafluorobenzene) porphine (PtTFPP) (purchased from sigma company), coumarin 6 (C6) (purchased from sigma company) were formulated into 1mg / mL tetrahydrofuran solution respectively; Platinum (II) MESO-tetrakis(pentafluorobenzene) porphine (PtTFPP, 1mg / mL), coumarin 6 (C6, 1mg / mL), and amphiphilic silane (7.5mg / mL) were placed on a magn...

Embodiment 2

[0031] Embodiment 2 comparative example

[0032] Composite nano-oxygen sensing material (Fe 3 o 4 @PtTFPP@silane) Preparation

[0033] Repeat Example 1, the difference is that the functional oily molecule loaded this time does not contain coumarin 6 (C6) with fluorescent labeling function (purchased from sigma company). All the other steps are the same as in Example 1. The resulting product concentration was 0.168 mg / mL.

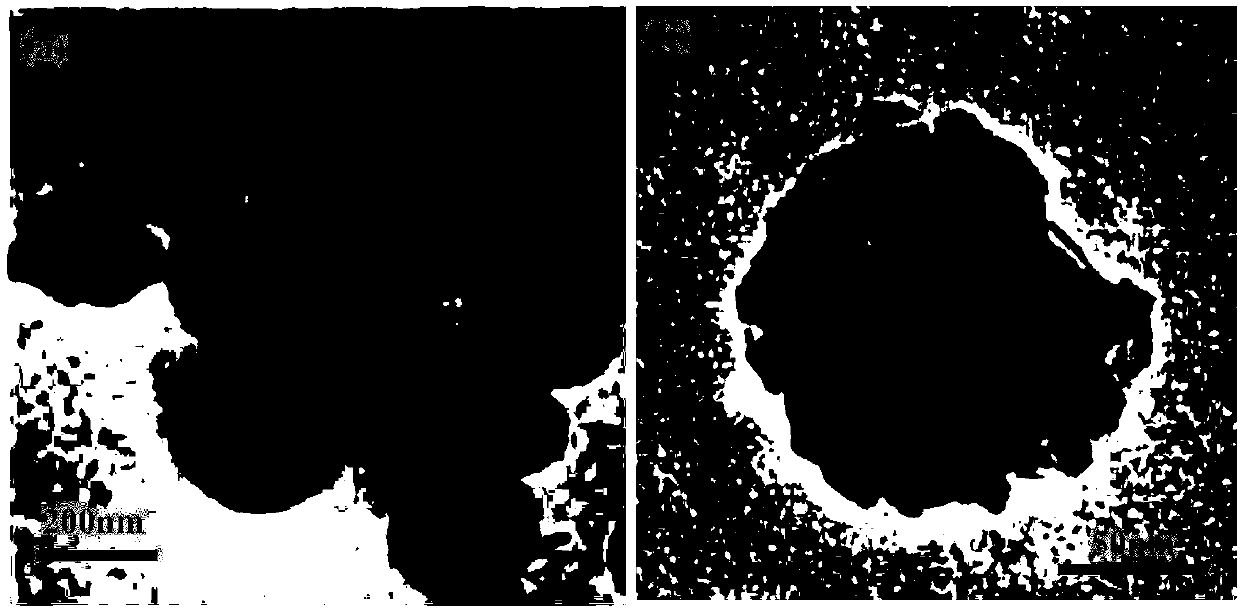

[0034] like figure 1 (a)(b):Fe 3 o 4 @PtTFPP / C6@silane NPs are well dispersed, with a thin transparent coating on the outer layer, and individual nanoparticles are spherical in shape with a diameter of about 100 nanometers. It can be seen that it is composed of many small ferric oxide nanoparticles. This is because ferric oxide nanoparticles will attract each other and agglomerate.

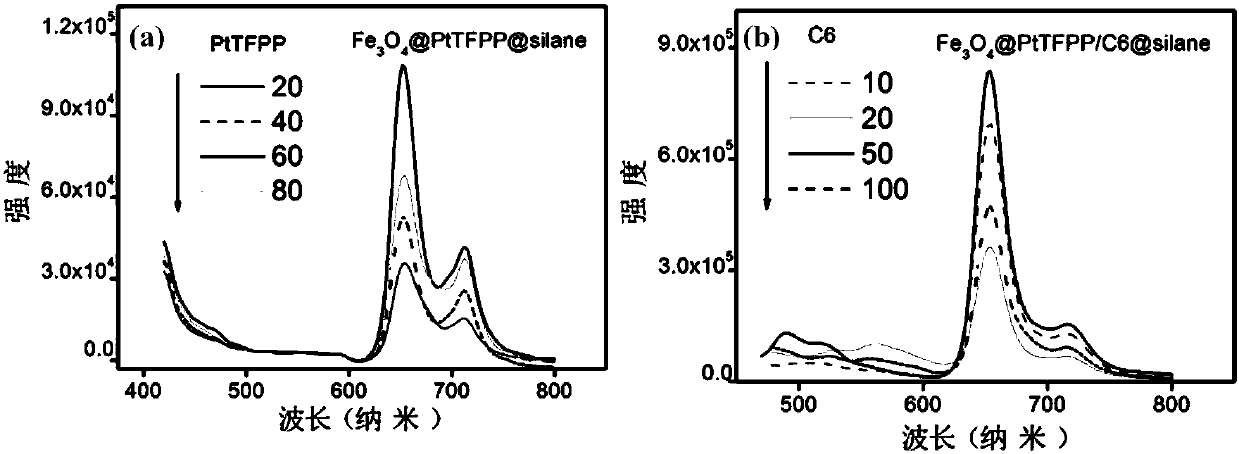

[0035] like figure 2 , according to the preparation method in Example 1, first determine the optimum concentration of PtTFPP, based on four different concentrations o...

Embodiment 3

[0043] Fe 3 o 4 @PtTFPP / C6 @silane and Fe 3 o 4 @PtTFPP @silane oxygen sensing test

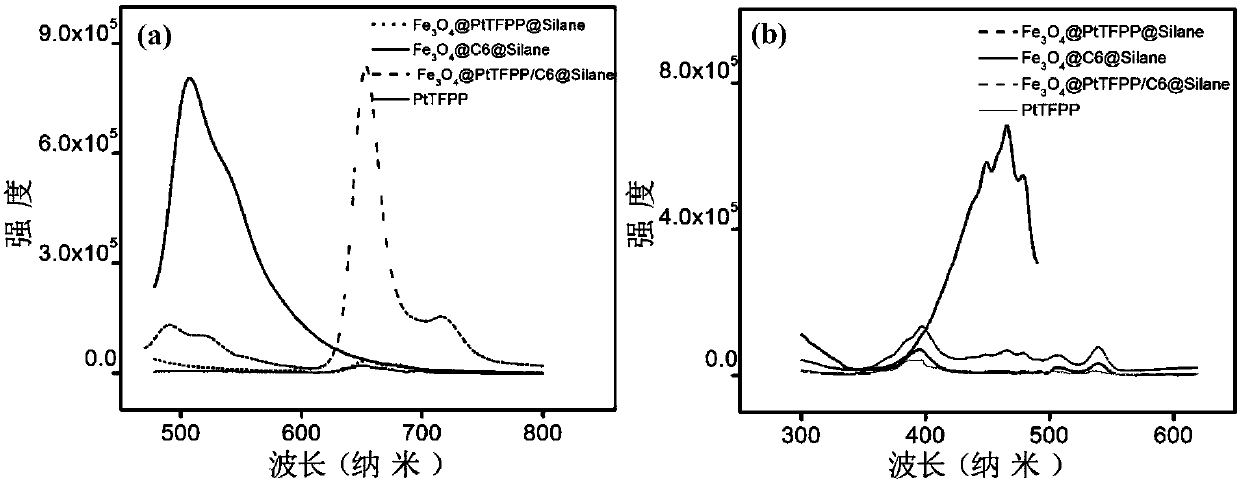

[0044] Excite Fe using 458nm excitation light 3 o 4 When @PtTFPP / C6@silane composites nanomaterials, because it contains platinum (Ⅱ) MESO-tetrakis(pentafluorobenzene) porphine, it will emit red light, and its peak position is at 652nm, and the intensity value of the emitted light varies with changes with the surrounding oxygen content. However, coumarin 6 (C6) emits green light, and its peak position is at 500nm, and the intensity of the emitted light does not change with the change of the surrounding oxygen content. When using a gas mixer to configure mixed gases with different oxygen contents (volume fractions of oxygen are 0, 20, 40, 60, 80, 100% respectively), pass it into the sealed cuvette, each time Continue for 20 minutes, so that the gas in the cuvette reaches an equilibrium state. Finally, the composite nanomaterial in the cuvette is tested for fluorescence emission spectru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com