Thin film transistor comprising light shielding layer, and preparation method of thin film transistor

A technology of thin-film transistors and light-shielding layers, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, and electric solid-state devices. It can solve problems such as circuit instability, increased circuit complexity, and power consumption, so as to improve efficiency and reduce photolithography steps. , The effect of simple preparation process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] figure 2 It is a flowchart of a method for manufacturing a thin film transistor according to an embodiment of the present application.

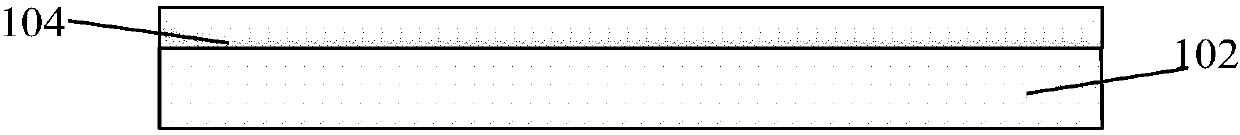

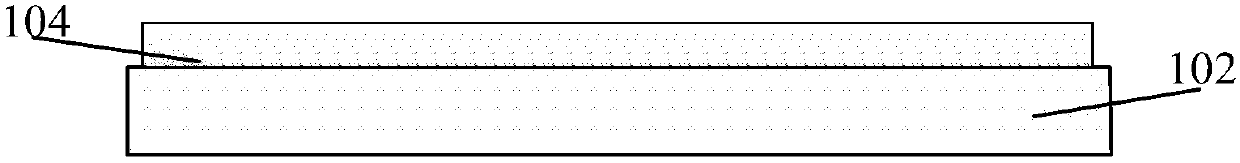

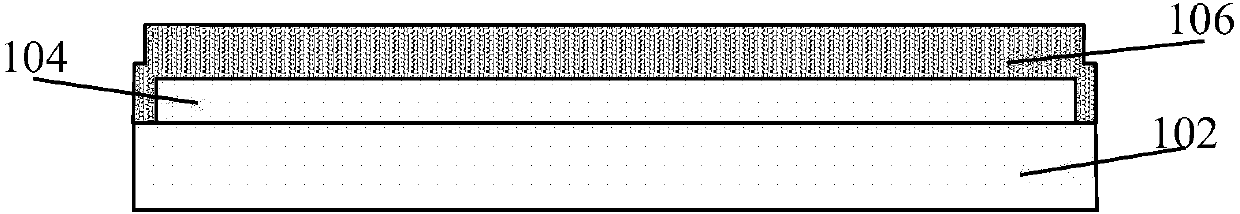

[0038] In S202, such as Figure 1a As shown, a layer of light-shielding layer 104 can be deposited on the substrate 102 first, such as Figure 1b The light shielding layer 104 is shown patterned. The substrate 102 may be a transparent material such as a glass substrate or a flexible substrate.

[0039]At present, metal materials are still used when preparing the light-shielding layer, although metal materials may have a series of defects. This is because, firstly, many non-metallic materials are transparent, and secondly, the light-shielding property is not the only requirement for the light-shielding layer material of the thin film transistor. To be used as a shading material also needs to meet the following series of requirements. It is beyond the reach of traditional technologies to find such a material that can be applied to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com