Microelectrolytic coupling anoxic bioreacting device and method for treating coal-to-gas wastewater phenolic substance by utilizing device

A technology of biological reaction device and biological reaction tank, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. The problems of large land area and easy passivation of iron-carbon fillers can achieve the effect of not easy to harden, reduce floor space, and short hydraulic retention time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

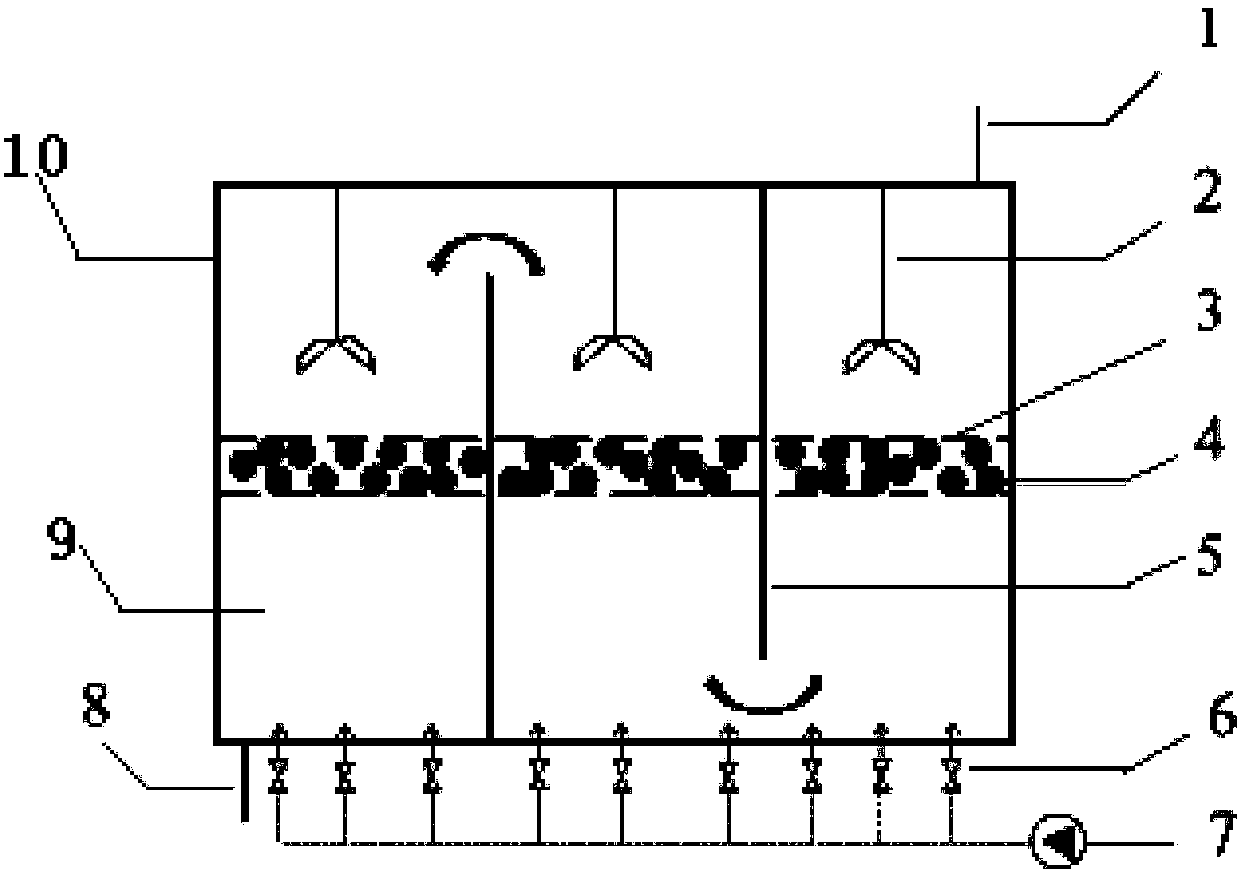

[0016] Embodiment 1: A micro-electrolysis coupled anoxic biological reaction device in this embodiment includes an anoxic biological reaction tank 10, a mechanical stirring device 2, a microporous aeration device 6 and an aeration pump 7; wherein the anoxic biological reaction tank 10 The grid 5 is divided into 3 baffled series reaction zones 9, the top of each reaction zone 9 is provided with a mechanical stirring device 2, the middle part is provided with an iron-carbon filler support grid, and the bottom is provided with a microporous gas blasting device 6, a microporous The detonation device 6 is connected with the aeration pump 7 through the aeration pipe; the anoxic biological reaction tank 10 is provided with a water inlet pipe 1 at the top and a water outlet pipe 8 at the bottom.

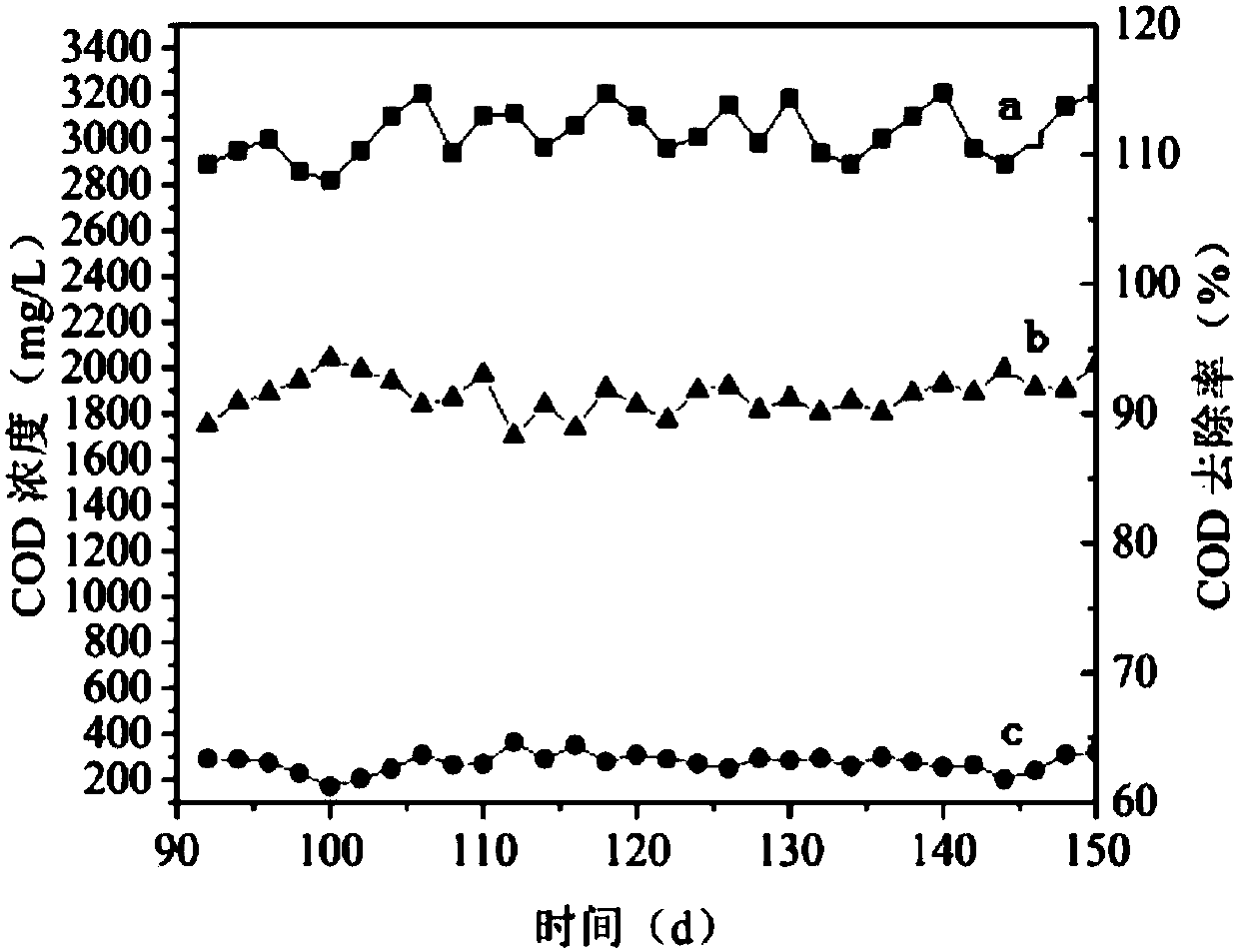

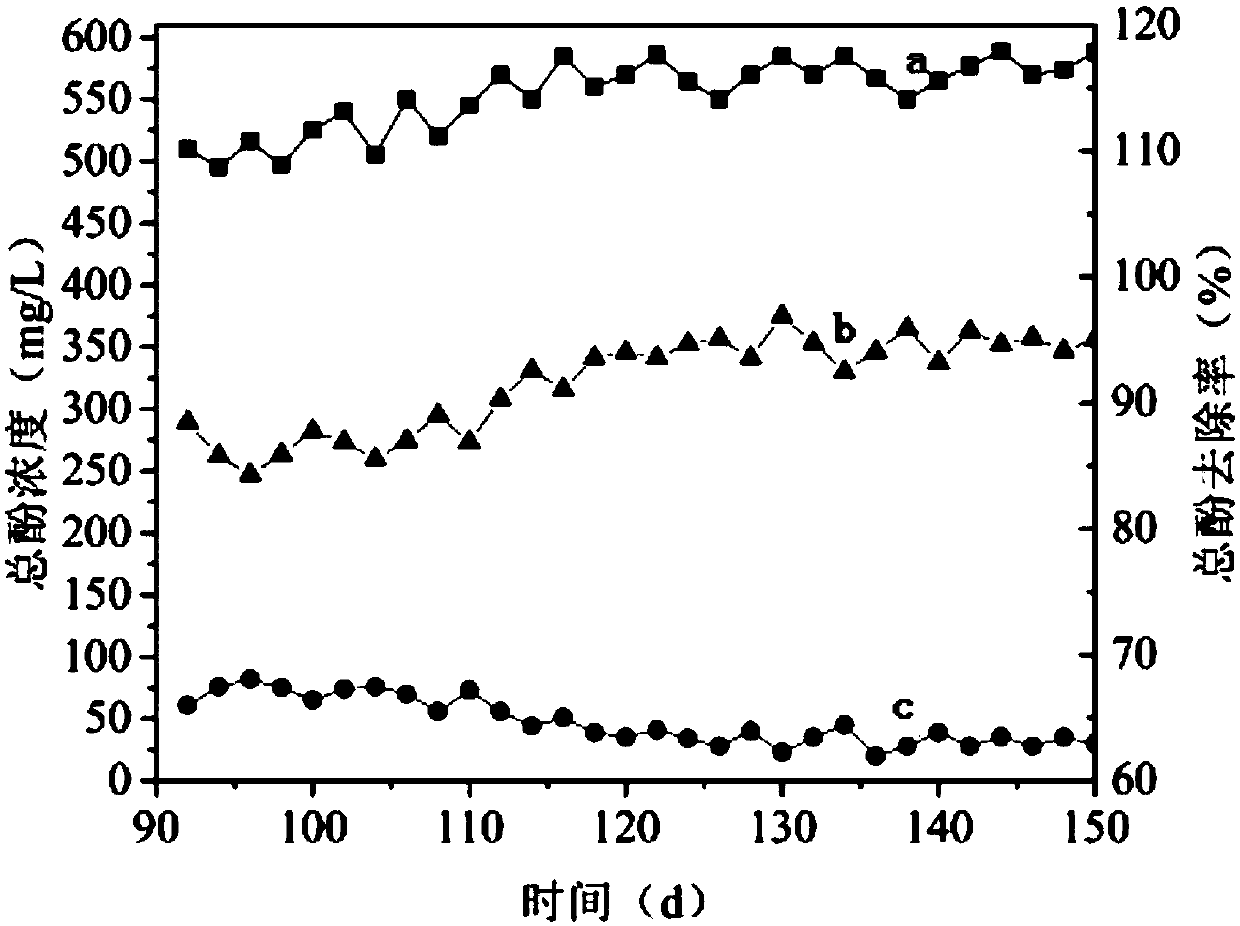

[0017] The beneficial effects of this embodiment are as follows: (1) The sewage treatment efficiency is high, the COD removal rate is as high as 93%, the total phenol removal rate is as high ...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the iron-carbon filler support grid is composed of an iron-carbon supporting steel mesh 3 and a composite iron-carbon micro-electrolytic filler 4, and the others are the same as those of Embodiment 1.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the diameter of the iron-iron-carbon supporting steel mesh 3 is 5 mm, and the others are the same as Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com