Transformer oil and preparation method thereof

A technology for transformer oil and naphthenic base oil, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor anti-gassing performance improvement, not in line with the development direction of transformer oil, etc. The effect of improving gas performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

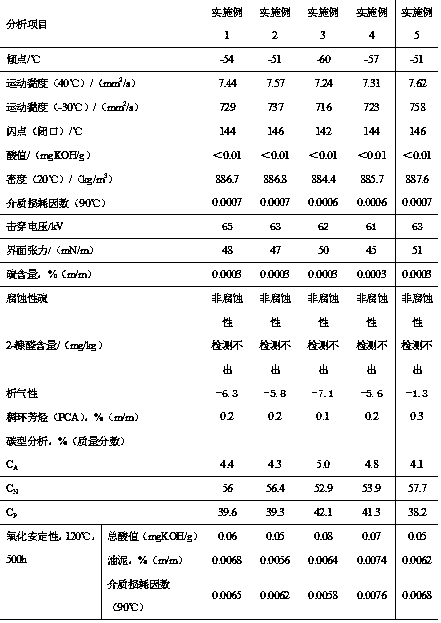

Examples

Embodiment 1

[0019] 1. Preparation of paraffinic base oil fractions

[0020] Firstly, the fraction of unsaturated chain hydrocarbons and monocyclic and polycyclic aromatic hydrocarbons with a viscosity of 5~9 (100°C) and a distillation range of 360~520°C (in this fraction, unsaturated chain hydrocarbons and monocyclic and polycyclic aromatic hydrocarbons account for 30-55% of the mass of the distillate) is used as the raw material through the hydrocracking reactor. During the reaction, the reaction temperature is 380~420°C, the reaction pressure is 14~16MPa, the reaction hydrogen oil volume ratio is 800~1600, and the space velocity is 0.4~1.0 / h; then through the hydroisomerization reactor, the reaction temperature in the process is 320~390℃, the reaction pressure is 14~16MPa, the reaction hydrogen oil ratio is 600~1200, and the space velocity is 0.6~1.2 / h; then hydrogenation Refining reactor, during the reaction, the reaction temperature is 230~290℃, the reaction pressure is 14~16MPa, the...

Embodiment 2

[0030] The preparation methods of paraffin base oil fraction, naphthenic base oil and transformer oil in this embodiment are all the same as in embodiment 1.

[0031] The difference from Example 1 is that in the transformer oil raw material prepared in this example, in terms of mass percentage, paraffinic base oil fraction accounts for 17.6%, alkylnaphthalene accounts for 0.8%, dodecylbenzene accounts for 5%, 2, 6-di-tert-butyl-p-cresol accounts for 0.3%, which is supplemented to 100% with naphthenic base oil.

Embodiment 3

[0033] The preparation methods of paraffin base oil fraction, naphthenic base oil and transformer oil in this embodiment are all the same as in embodiment 1.

[0034] The difference from Example 1 is that in the transformer oil prepared in this example, by mass percentage, paraffinic base oil fractions account for 25%, alkylnaphthalene accounts for 1%, dodecylbenzene accounts for 6%, 2,6 -Di-tert-butyl-p-cresol accounts for 0.35%, which is supplemented to 100% with naphthenic base oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com