Automatic skin-brushing and cleaning machine for purple sweet potatoes

A washing machine, automatic technology, applied in application, food processing, food science and other directions, can solve the problems of large water consumption, slow cleaning speed, complicated operation, etc., to achieve the effect of reducing labor intensity, fast cleaning speed, and simple and cheap operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

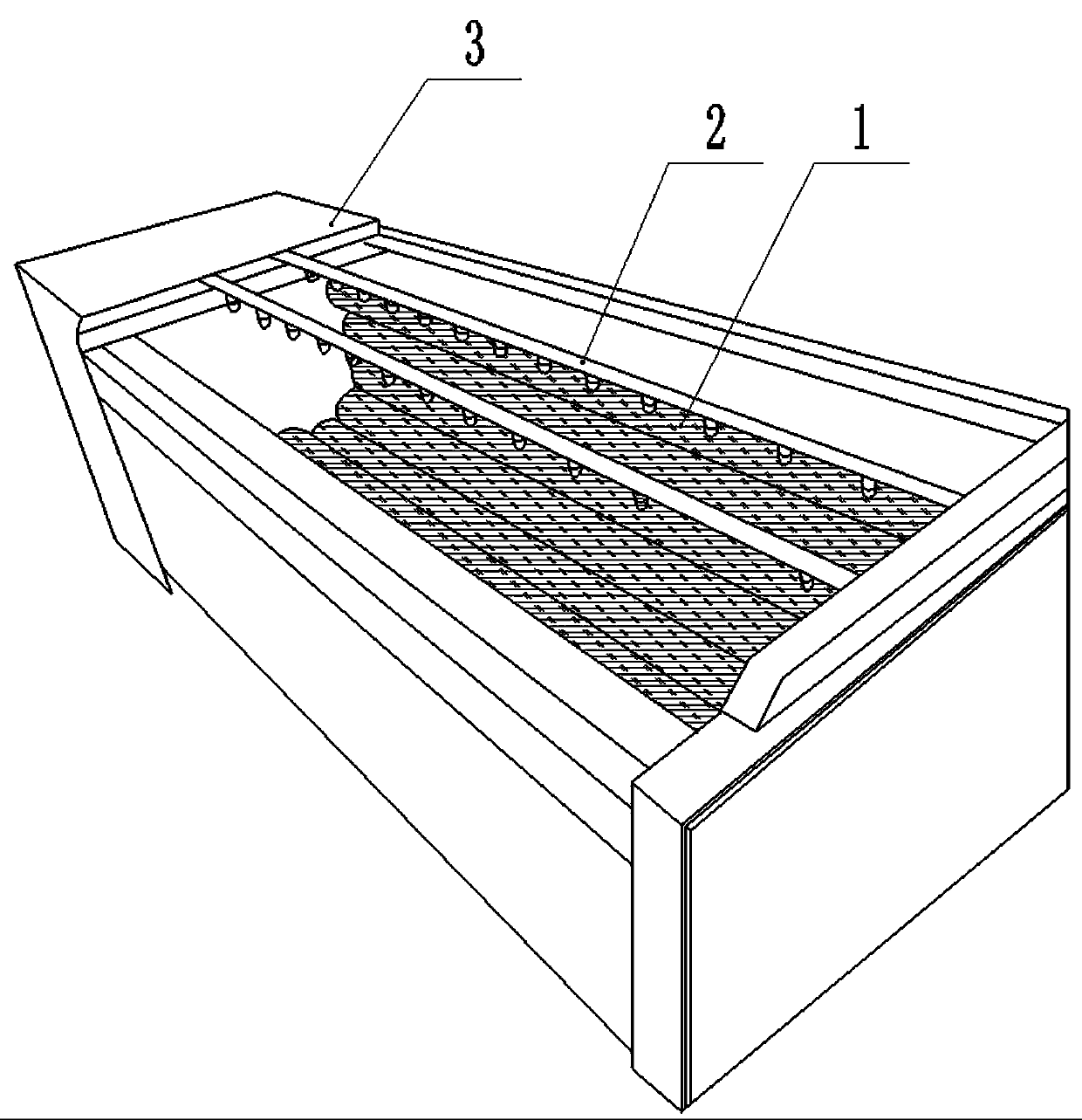

[0013] refer to figure 1 , an automatic cleaning machine for purple potato skins, which consists of two groups of brush rollers, spray pipes, motors and differentials. The spray pipes are evenly arranged above the brush rollers and connected to the motor. The motor also passes through the differential Connect with brush roller. The brush roller is composed of a metal shaft, a brush filament attachment arranged on the metal shaft and brush filaments evenly surrounding the brush filament attachment, wherein the brush filament is a polymer material containing Teflon.

[0014] In this embodiment, the brush filaments are antibacterial nylon 1010 temperature-resistant and wear-resistant brush filaments.

[0015] When working, put the purple sweet potato into the washing machine, turn on the motor, two sets of 12 brush rollers rotate relative to scrape the surface, and the brush wires are evenly cleaned to the surface of the purple sweet potato, which improves the cleaning coverage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com