Whitening moisturizing cosmetic and preparation method thereof

A cosmetic and whitening technology, applied in the field of whitening and moisturizing cosmetics and its preparation, can solve the problems of uncoordinated absorption, insignificant whitening effect, slow curative effect, etc., achieve coordination of fusion and absorption, improve whitening and moisturizing performance, and improve whitening effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

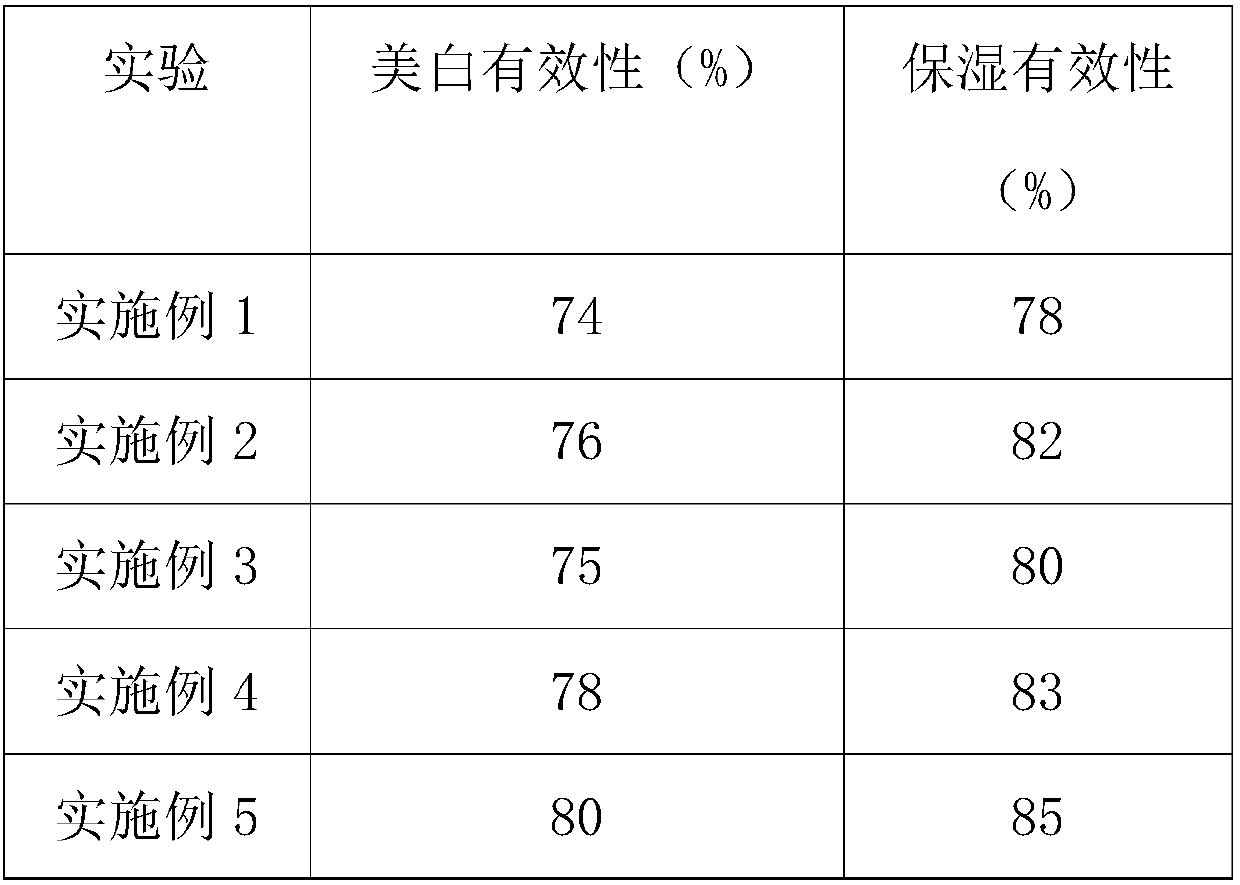

Examples

Embodiment 1

[0019] S1: Grind 8 parts of aloe vera, 7 parts of lemon and 20 parts of tomato to 100 mesh, then put them into an extraction container, add 50 parts of 50% aqueous acetic acid solution to it, and stir and extract at a rate of 600r / min at a temperature of 40°C 3h, take the residue after filtration, and keep the filtrate A;

[0020] S2: Add the same amount of 50% acetic acid aqueous solution as in step S1 to the residue, stir and extract at a rate of 900 r / min at a temperature of 60° C. for 1 hour; filter, and retain the filtrate B;

[0021] S3: Mix 7 parts of kojic acid, 5 parts of methacrylate, 6 parts of laureth, 10 parts of tocopheryl acetate, 9 parts of dioctyl carbonate and 10 parts of butylene glycol, and add step S1 thereto The filtrate A and the filtrate B described in step S2; stirred and reacted at a temperature of 70° C. for 1 h; then heated and concentrated to 30% to obtain the whitening cosmetic.

Embodiment 2

[0023] S1: Grind 12 parts of aloe vera, 10 parts of lemon and 10 parts of tomato to 80 mesh, then put them into an extraction container, add 70 parts of 50% aqueous acetic acid solution, and stir and extract at a temperature of 60°C at a rate of 700r / min 2h, take the residue after filtration, and keep the filtrate A;

[0024] S2: Add the same amount of 50% acetic acid aqueous solution as in step S1 to the residue, stir and extract at a temperature of 80° C. at a rate of 1000 r / min for 2 hours; filter, and retain the filtrate B;

[0025] S3: Mix 10 parts of kojic acid, 10 parts of methacrylate, 9 parts of laureth, 12 parts of tocopheryl acetate, 14 parts of dioctyl carbonate and 15 parts of butylene glycol, and add step S1 thereto The filtrate A and the filtrate B described in step S2; stirred and reacted at a temperature of 90° C. for 2 hours; then heated and concentrated to 50% to obtain the whitening cosmetic.

Embodiment 3

[0027] S1: Grind 10 parts of aloe vera, 9 parts of lemon and 12 parts of tomato to 90 mesh, then put them into an extraction container, add 55 parts of 50% acetic acid aqueous solution to it, and stir and extract at a rate of 650r / min at a temperature of 45°C 2h, take the residue after filtration, and keep the filtrate A;

[0028] S2: Add the same amount of 50% acetic acid aqueous solution as in step S1 to the residue, stir and extract at a temperature of 75° C. at a rate of 950 r / min for 1 hour; filter, and retain the filtrate B;

[0029] S3: Mix 8 parts of kojic acid, 9 parts of methacrylate, 8 parts of laureth, 10 parts of tocopheryl acetate, 10 parts of dioctyl carbonate and 14 parts of butylene glycol, and add step S1 thereto The filtrate A and the filtrate B described in step S2; stirred and reacted at a temperature of 75° C. for 1 h; then heated and concentrated to 35% to obtain the whitening cosmetic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com