Dry space wet space separated facial mask, and preparation method and applications thereof

A dry-wet separation and facial mask technology, which is applied in the direction of cosmetic preparations, dressing preparations, skin care preparations, etc., can solve the problems of excessive mask ingredients, ineffective effects, insufficient safety and stability, etc., to achieve The effect of simple preparation method, soft hand feeling, high commercial value and potential value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Utilize film dispersion method to prepare polypeptide liposome, step:

[0040] Step 1: Accurately weigh 300mg of soybean lecithin, 100mg of cholesterol, and 10mg of polypeptide into a 500ml round bottom flask, and dissolve in 60ml of chloroform / methanol mixed solvent with a volume ratio of 2:1.

[0041] Step 2: Add 25 glass beads, rotate under reduced pressure on a 40°C water bath to form a thin film, take 20ml of PBS buffer, heat to 55°C, pour into a flask, and stir in a 55°C water bath for 30 minutes to hydrate the lipid film fall off.

[0042] Step 3: pass through a 450nm microporous membrane to obtain a liposome suspension, freeze and dry to obtain a dry polypeptide liposome powder.

Embodiment 2

[0044] The preparation of liposome facial mask containing polypeptide, steps:

[0045] Step 1: Weigh 10 mg of liposome dry powder and add it to 2 ml of deionized water, and ultrasonically disperse for 15 minutes to obtain a suspension of polypeptide liposome;

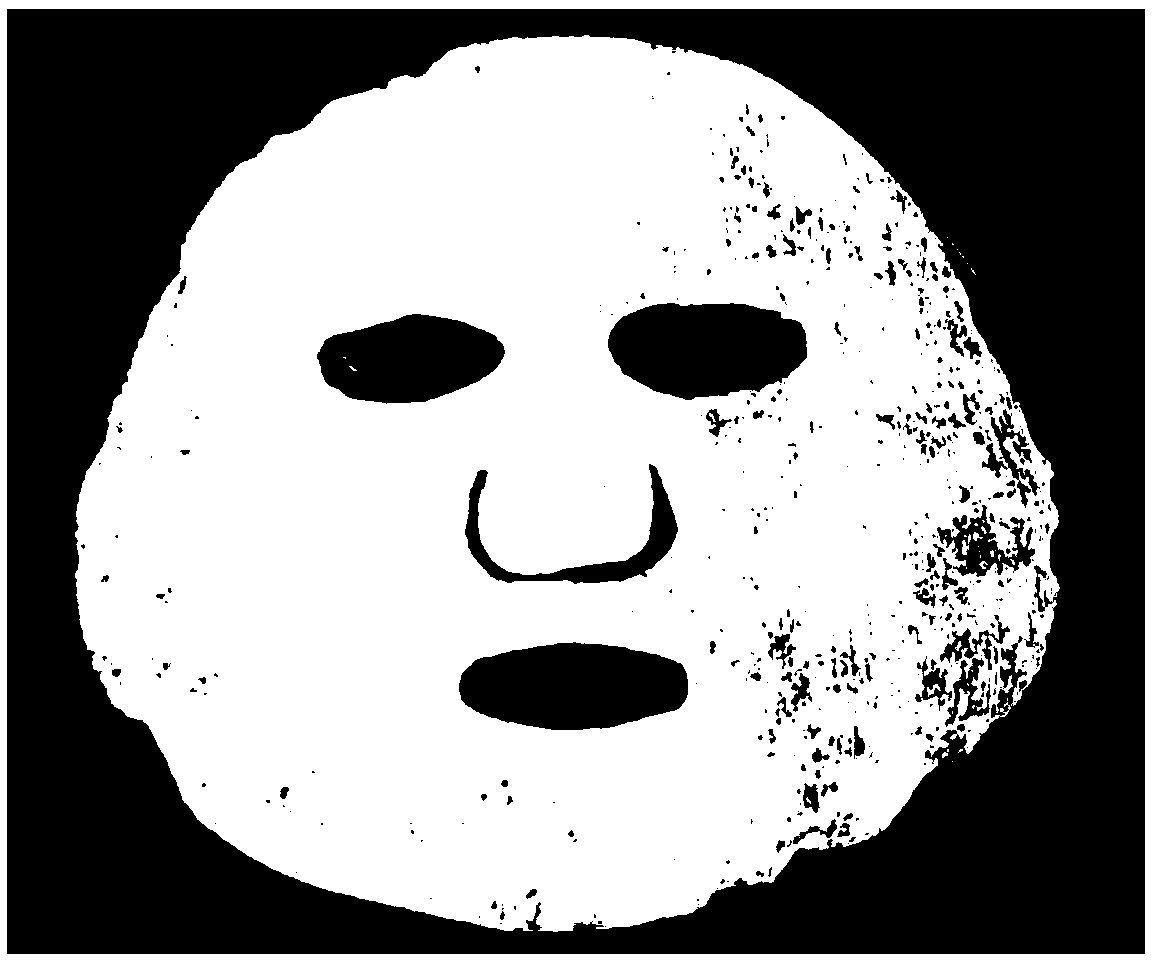

[0046] Step 2: Use an electrostatic spray device to evenly spray 2 mL of the above solution on 1.5 g of blank mask paper to obtain a liposome-containing mask, which is component A, see figure 2 .

Embodiment 3

[0048] The preparation of component B, step:

[0049] Component B was obtained by adding 8 ml of deionized water to an 8 ml spray bottle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com