Treatment method for low-temperature methanol washing exhaust gas

A technology of low-temperature methanol washing and treatment method, which is applied to fixed tubular conduit components, heat exchanger types, lighting and heating equipment, etc., can solve problems such as energy waste, and achieve the effect of saving consumption and increasing discharge temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

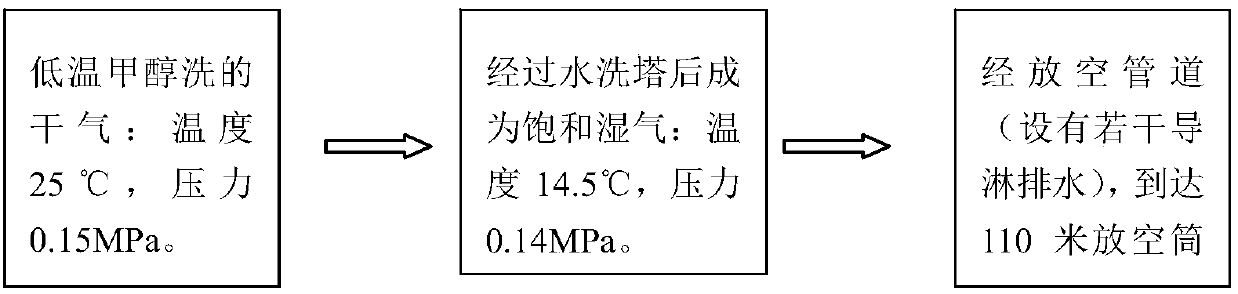

Problems solved by technology

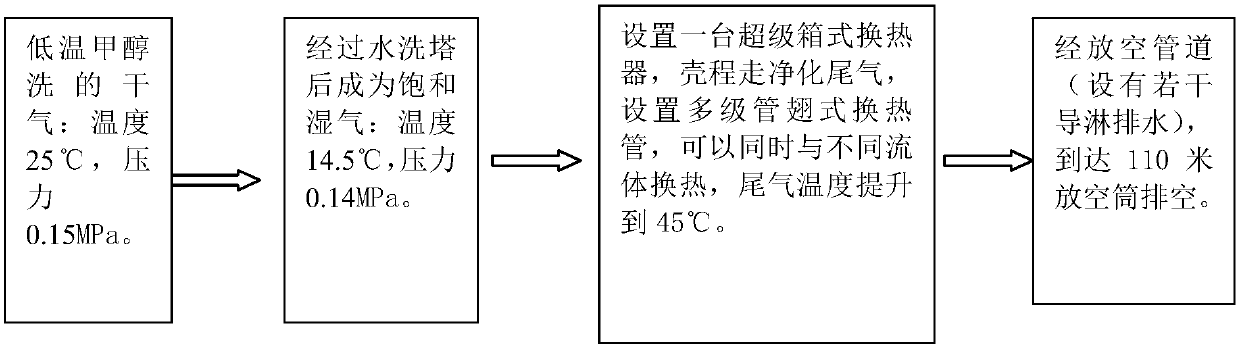

Method used

Image

Examples

Embodiment 1

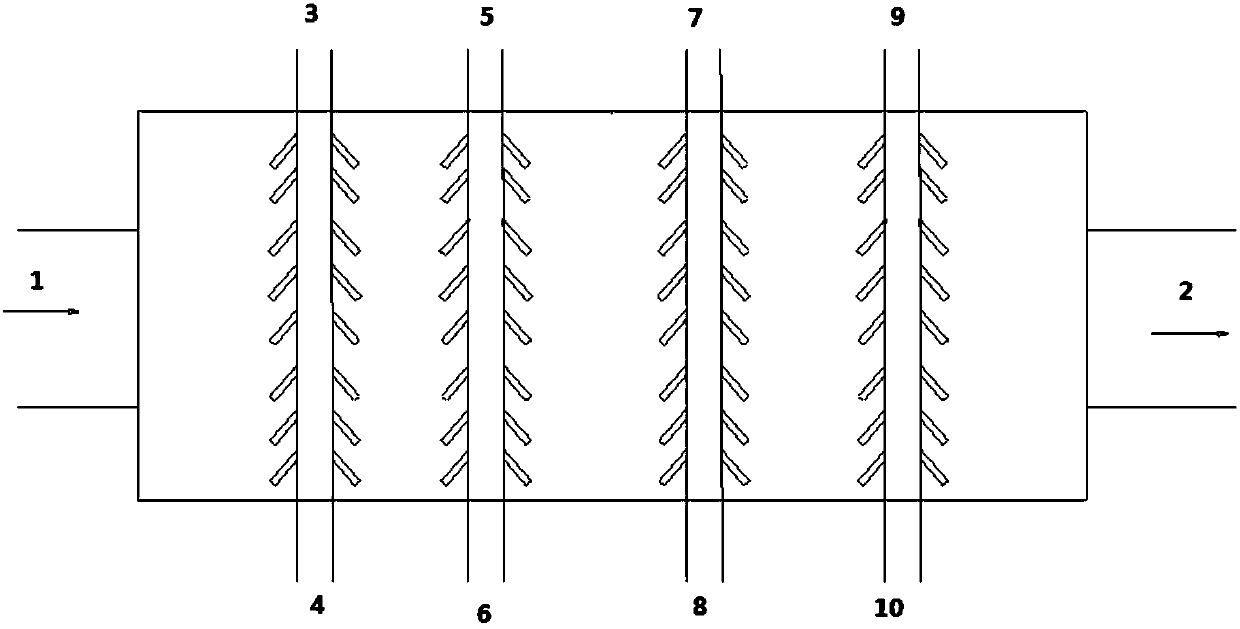

[0028] Taking the low-temperature methanol washing process of 600,000 tons of methanol in Dalian University of Technology as an example, the following methods are used: image 3 The shown heat exchange box performs heat exchange on low-temperature methanol scrubbing tail gas, and the data are shown in Table 1.

[0029] Table 1

[0030]

[0031] (1) Increase the discharge temperature to 45°C, and the energy that can be recovered per year (8000 hours) is calculated as follows:

[0032] 165934kg / h×(45-15)×0.8842kJ / kg.K×8000h=35212522272kJ / a

[0033] Equivalent standard coal: (35212522272kJ / a) / 7000×4.18=120.34t standard coal

[0034] (2) The cooling capacity recovered each year can recover condensed water (the specific heat of water is 4.2kJ / kg, and the condensed water is reduced from 85°C to 45°C)

[0035] (35212522272kJ / a) / 4.2kJ / kg*(85-45)=209598t

[0036] That is, 210,000 tons of desalted water can be recovered every year.

[0037] (3) Raising the discharge temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com