Platinum/alumina catalyst as well as preparation method and application thereof

A kind of alumina and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Problems such as fluctuations are prone to occur, achieving good application prospects, reducing the risk of high pressure and high temperature, and the effect of continuous production of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

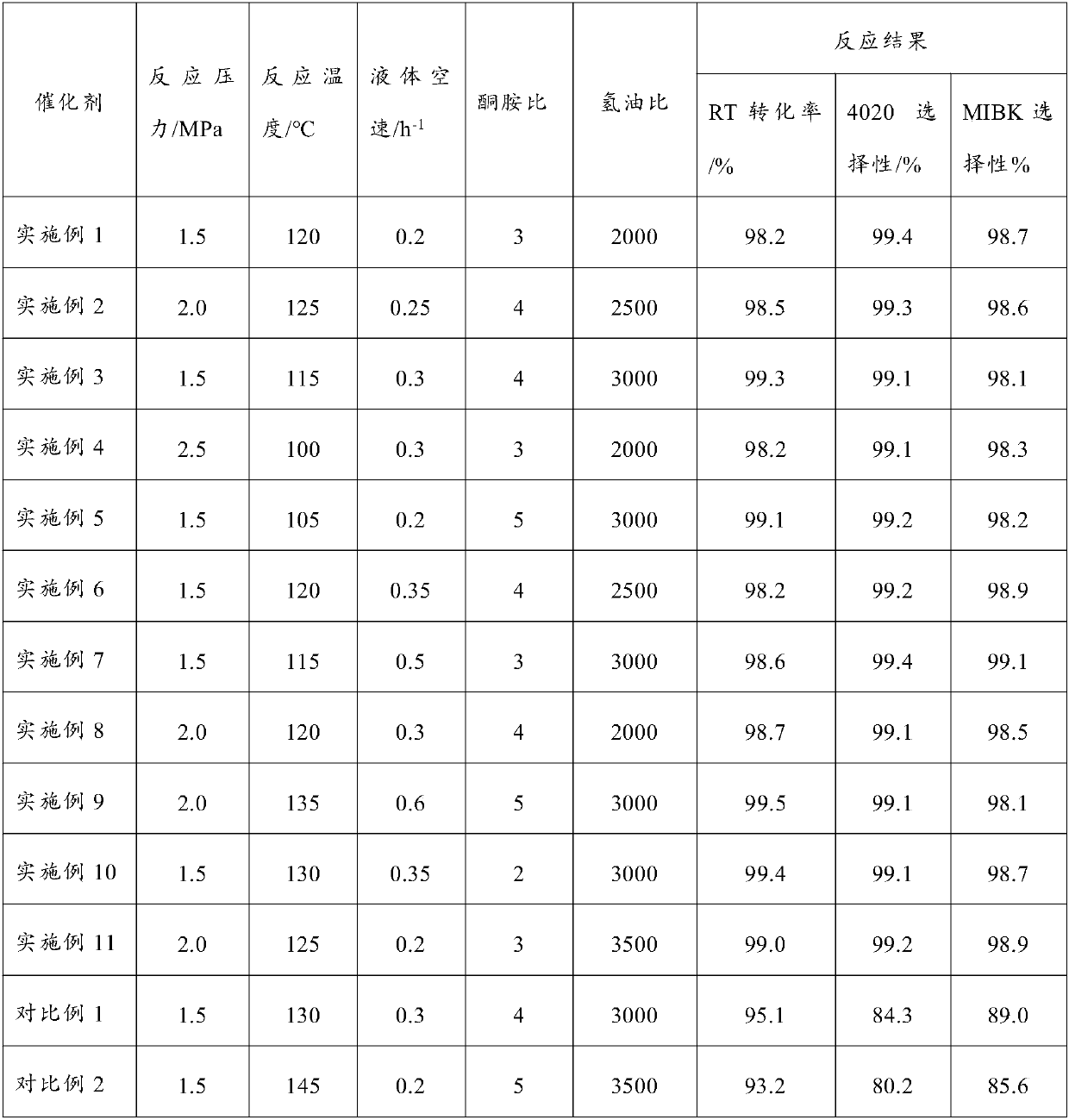

Examples

Embodiment 1

[0058] (1) Carrier pretreatment

[0059] a. Prepare 150 ml of hydrochloric acid with a concentration of 0.1 mol / L, weigh 3 g of polyvinylpyrrolidone-K30, 150 g of heptane, and 150 g of butanol, add them to a 5000 ml three-necked flask, and vigorously stir and mix to form the first type of emulsion;

[0060] b. Prepare 410ml of germanium tetrachloride tetrahydrofuran solution with a concentration of 1wt%, weigh 90g of heptane, add it to a 2000ml three-necked flask, and stir to form the second type of emulsion;

[0061] c. Add the second type of emulsion into the first type of emulsion under stirring conditions, and after ultrasonic treatment, continue to stir for 10 minutes to obtain a mixed solution;

[0062] d. Add an accurately weighed specific surface area of 20m to the mixed solution 2 / g, 200g spherical alumina carrier with an average pore diameter of 55nm and a diameter of 1.5-2.5mm, stirred slowly at a temperature of 50°C, kept for 6 hours, washed with deionized wate...

Embodiment 2

[0071] (1) Carrier pretreatment

[0072] a. Prepare 150 ml of hydrochloric acid with a concentration of 0.1 mol / L, weigh 3 g of polyvinylpyrrolidone-K30, 150 g of heptane, and 150 g of butanol, add them to a 5000 ml three-necked flask, and vigorously stir and mix to form the first type of emulsion;

[0073] b. Prepare 410ml of germanium tetrachloride tetrahydrofuran solution with a concentration of 1wt%, weigh 90g of heptane, add it to a 2000ml three-necked flask, and stir to form the second type of emulsion;

[0074] c. Add the second type of emulsion into the first type of emulsion under stirring conditions, and after ultrasonic treatment, continue to stir for 10 minutes to obtain a mixed solution;

[0075] d. Add an accurately weighed specific surface area of 20m to the mixed solution 2 / g, 200g spherical alumina carrier with an average pore diameter of 55nm and a diameter of 1.5-2.5mm, stirred slowly at a temperature of 50°C, kept for 6 hours, washed with deionized wate...

Embodiment 3

[0084] (1) Carrier pretreatment

[0085] a. Prepare 200 ml of hydrochloric acid with a concentration of 0.1 mol / L, weigh 5 g of polyvinylpyrrolidone-K30, 200 g of heptane, and 200 g of butanol, add them to a 5000 ml three-necked flask, and vigorously stir and mix to form the first type of emulsion;

[0086] b. Prepare 1025ml of germanium tetrachloride tetrahydrofuran solution with a concentration of 2wt%, weigh 125g of heptane, add it to a 2000ml three-necked flask, and stir to form the second type of emulsion;

[0087] c. Add the second type of emulsion into the first type of emulsion under stirring conditions, and after ultrasonic treatment, continue to stir for 10 minutes to obtain a mixed solution;

[0088] d. Add an accurately weighed specific surface area of 15m to the mixed solution 2 / g, with an average pore diameter of 65nm and a diameter of 1.5-3.0mm spherical alumina carrier 200g, at a temperature of 60°C, stir slowly, keep for 6 hours, wash with deionized water u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com