Purification method of flavored mogroside V

A mogroside and purification method technology, which is applied to the purification field of mogroside V, can solve the problems of a large proportion of non-glucoside components in solids, incomparable flavor and taste, and inability to remove, and achieves stable and uniform properties. The effect of good sex and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

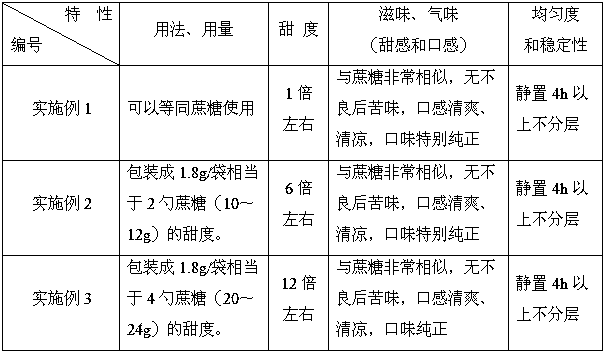

Embodiment 1

[0047] (1) Polyamide adsorption: Dissolve 1kg of mogroside crude extract I with 8L of water first, and then put the mogroside aqueous solution on a polyamide resin chromatography column at a flow rate of 1BV / h (the mesh number of the polyamide resin is 100 mesh , the dosage is 2kg, the height-to-diameter ratio of the polyamide column is 5:1), and the effluent is collected;

[0048] (2) Alkali adjustment and ultrafiltration: use lye to adjust the pH value of the effluent obtained in step (1) to 10, let it stand for 4 hours, perform coarse filtration, and then use an ultrafiltration membrane with a molecular weight cut-off of 6000D to collect the filtrate;

[0049] (3) Ion exchange adsorption: Put the filtrate obtained in step (2) on a cation exchange resin column (the model of the cation exchange resin is 001×7, the dosage is 2kg, and the ratio of height to diameter of the cation exchange resin column is 6:1) and anion exchange resin column. Exchange resin column (the type of a...

Embodiment 2

[0053] (1) Polyamide adsorption: Dissolve 2kg of mogroside crude extract I in 20L of water first, and then put the mogroside aqueous solution on a polyamide resin chromatography column at a flow rate of 0.5BV / h (the mesh size of the polyamide resin is 200 mesh, the dosage is 6kg, the height-to-diameter ratio of the polyamide column is 8:1), and the effluent is collected;

[0054] (2) Alkali adjustment and ultrafiltration: use lye to adjust the pH value of the effluent obtained in step (1) to 10, let it stand for 6 hours, perform coarse filtration, and then use an ultrafiltration membrane with a molecular weight cut-off of 4000D to collect the filtrate;

[0055] (3) Ion exchange adsorption: Put the filtrate obtained in step (2) on the cation exchange resin column (the model of the cation exchange resin is 001×16, the dosage is 7kg, and the height-to-diameter ratio of the cation exchange resin column is 10:1) and the anion exchange resin column. Exchange resin column (the type o...

Embodiment 3

[0059] (1) Polyamide adsorption: Dissolve 1kg of mogroside crude extract II in 10L of water first, then put the mogroside aqueous solution on a polyamide resin chromatography column at a flow rate of 2BV / h (the mesh number of the polyamide resin is 150 mesh , the dosage is 2.5kg, the height-to-diameter ratio of the polyamide column is 10:1), and the effluent is collected;

[0060] (2) Alkali adjustment and ultrafiltration: use lye to adjust the pH value of the effluent obtained in step (1) to 9.5, let it stand for 5 hours, perform coarse filtration, and then use an ultrafiltration membrane with a molecular weight cut-off of 5000D to collect the filtrate;

[0061] (3) Ion exchange adsorption: Put the filtrate obtained in step (2) on the cation exchange resin column in turn (the model of the cation exchange resin is 001×8, the dosage is 2.5kg, and the height-to-diameter ratio of the cation exchange resin column is 10:1) and Anion exchange resin column (the type of anion exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com