Energy-saving boiler with flue gas treatment function

A flue gas treatment and function technology, applied in the field of boilers, can solve the problems of low boiler thermal efficiency and large environmental pollution, and achieve the effects of purifying flue gas, eliminating pollution and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

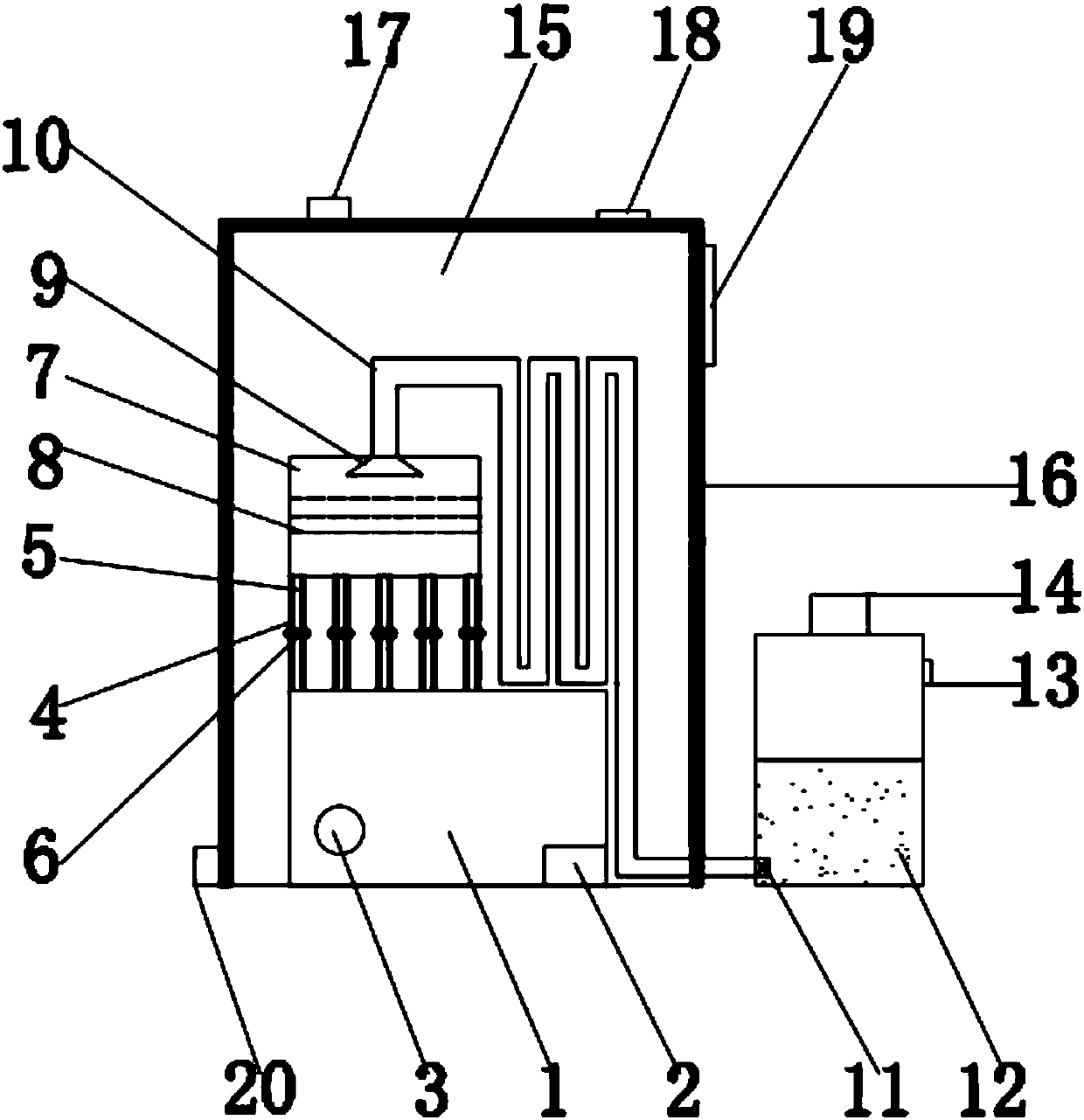

[0016] Such as figure 1 As shown, the present invention provides an energy-saving boiler with flue gas treatment function, comprising a combustion chamber 1, a slag outlet 2 is provided at the bottom of the combustion chamber 1, a gas port 3 is provided in the combustion chamber 1, and a gas outlet 3 is provided at the top of the combustion chamber 1 Pyrotechnic passage 4, inside pyrotechnic passage 4 is provided with fire distribution pipe 5, and fire distribution pipe 5 is fixed in pyrotechnic passage 4 through support 6, and the top of pyrotechnic passage 4 is provided with smoke collection box 7, and the middle part of smoke collection box 7 is provided with dust-shielding net 8. The upper part of the dust-shielding net 8 is provided with a fire distribution cover 9, and the top of the fire distribution cover 9 is connected with a serpentine pipe 10, and the end of the serpentine pipe 10 is provided with a smoke outlet valve 11, and the end of the smoke outlet valve 11 is c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap