External combined heat pipe

An external heat pipe technology, applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of heat exchanger installation, transportation impact, heat exchanger hot water storage decline, large metal pipe size, etc., to achieve reduction Small size and installation weight, increased heat transfer efficiency, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

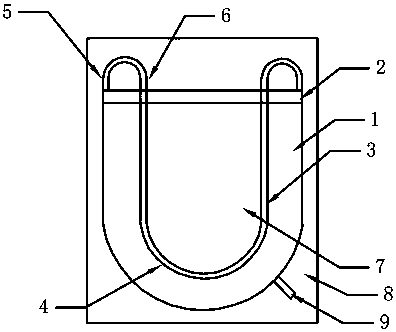

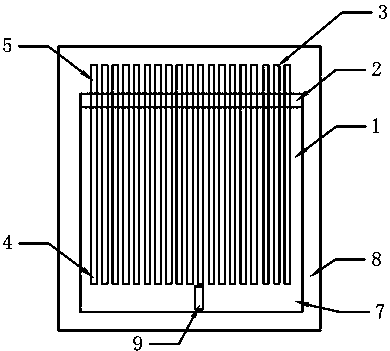

[0019] Such as Figures 1 to 2 As shown, an external combined heat pipe includes a U-shaped housing 1, a bracket 2 fixedly connected to the opening of the U-shaped housing 1, and a plurality of miniature microchannel metal heat dissipation round tubes 3. The miniature microchannels The metal heat dissipation circular tube 3 includes a condensation section 4, an adiabatic section 5, and an evaporation section 6, and it is characterized in that the support 2 is used to fixedly support the condensation section 4 of the plurality of miniature microchannel metal heat dissipation circular pipes 3, so The inner diameter of the miniature micro-channel metal heat dissipation circular tube 3 is 0.05-0.6mm, the wall thickness is 0.15-0.25mm, and the outer diameter is less than 0.9mm; there is a closed space 7 between the U-shaped housing 1 and the bracket 2; The thermal insulation section 5 and the evaporation section 6 of the miniature microchannel metal heat dissipation circular tube 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com