Continuous sampling apparatus and continuous sampling method for marine natural gas hydrate

A sampling device and hydrate technology, which is applied to the sampling device and other directions, can solve the problems of inability to realize continuous coring, drill bit frictional heat generation, hydrate decomposition, etc., and achieve the effects of simple structure, reduced hydrate decomposition, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

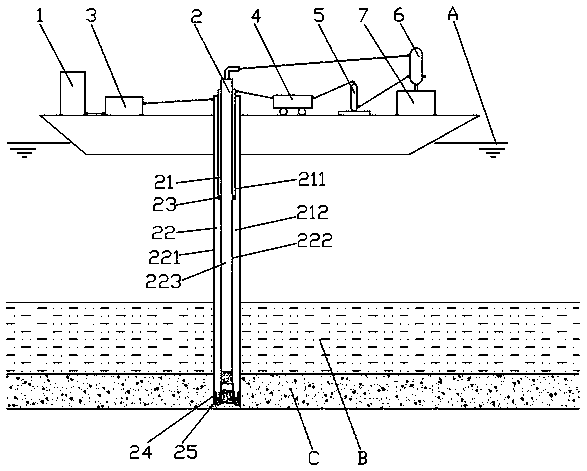

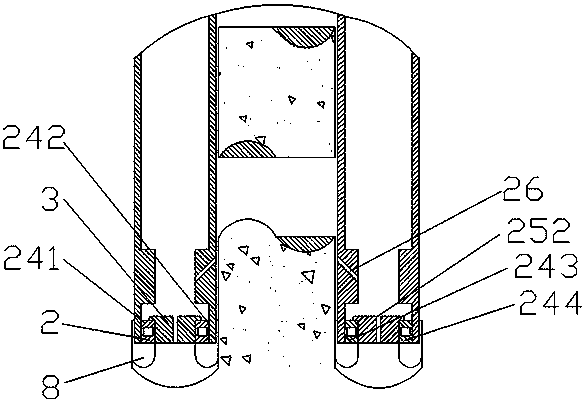

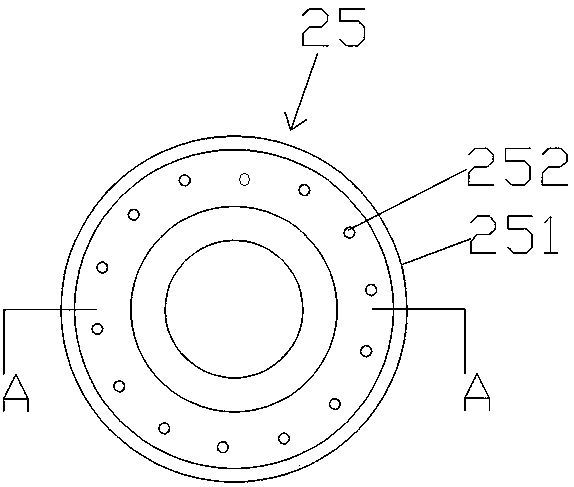

[0026] see figure 1 , figure 2 , image 3 and Figure 4 As shown, a continuous sampling device for marine natural gas hydrate of the present invention is composed of refrigeration equipment 1, single-action rotary sampling drilling tool 2, high-pressure plunger pump 3, air compression equipment 4, nitrogen production equipment 5, heat preservation The pressure-holding and separating device 6 is composed of the heat-preserving and pressure-holding ore body box 7, the refrigeration equipment 1, the single-action rotary sampling drilling tool 2, the high-pressure plunger pump 3, the air compression equipment 4, the nitrogen making equipment 5, the heat-preserving and pressure-holding separation device 6 and The thermal insulation and pressure holding ore body boxes 7 are connected by pipelines, and are fixedly arranged on the exploration ship in sequence, and the single-action rotary sampling drilling tool 2 is in contact with the marine natural gas hydrate formation;

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com