A kind of preparation method of silver-coated copper powder

A copper powder, silver-copper technology, applied in metal processing equipment, transportation and packaging, coating and other directions, can solve the problems of low efficiency of silver coating of silver-coated copper powder, poor quality of silver-coated layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

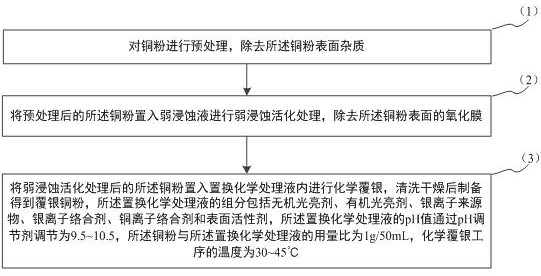

[0043] figure 1 It is a method flowchart of a method for preparing silver-coated copper powder shown according to an exemplary embodiment, such as figure 1 Shown, the preparation method of this silver-coated copper powder comprises the following steps:

[0044] Step (1): pretreating the copper powder to remove impurities on the surface of the copper powder.

[0045] Step (2): putting the pretreated copper powder into a weak etching solution for weak etching activation treatment to remove the oxide film on the surface of the copper powder.

[0046] Step (3): Put the copper powder after the weak etching and activation treatment into the replacement chemical treatment solution for chemical silver coating, and prepare silver-coated copper powder after cleaning and drying. The components of the replacement chemical treatment solution include inorganic Brightener, organic brightener, silver ion source, silver ion complexing agent, copper ion complexing agent and surfactant, the pH...

Embodiment 1

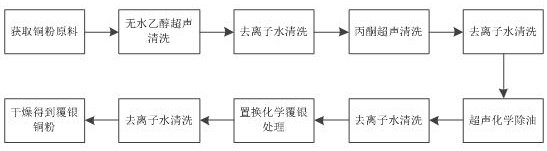

[0077] A) Put the copper powder into absolute ethanol for the first ultrasonic cleaning to remove the dust and stains on the surface of the copper powder. The temperature of the first ultrasonic cleaning process is 40°C and the time is 5 min.

[0078] B) putting the copper powder after ultrasonic cleaning for the first time into acetone for ultrasonic cleaning for the second time to remove oil stains on the surface of the copper powder.

[0079]C) Put the copper powder after the second ultrasonic cleaning into the degreasing liquid for chemical degreasing to obtain the pretreated copper powder, the components of the degreasing liquid include 12 g / L hydrogen Sodium oxide, 50 g / L of sodium carbonate and 5 g / L of sodium sulfate.

[0080] D) Put the pretreated copper powder into a weak etching solution for weak etching activation treatment to remove the oxide film on the surface of the copper powder. The components of the weak etching solution include 11 mL / L of sulfuric acid , 6...

Embodiment 2

[0087] A) Put the copper powder into absolute ethanol for the first ultrasonic cleaning to remove the dust and stains on the surface of the copper powder. The temperature of the first ultrasonic cleaning process is 42°C and the time is 6 minutes.

[0088] B) putting the copper powder after ultrasonic cleaning for the first time into acetone for ultrasonic cleaning for the second time to remove oil stains on the surface of the copper powder.

[0089] C) Put the copper powder after the second ultrasonic cleaning into the degreasing liquid for chemical degreasing to obtain the pretreated copper powder. The components of the degreasing liquid include 13g / L hydrogen peroxide Sodium, 55 g / L of sodium carbonate and 10 g / L of sodium sulfate.

[0090] D) Put the pretreated copper powder into a weak etching solution for weak etching activation treatment to remove the oxide film on the surface of the copper powder. The components of the weak etching solution include 12 mL / L of sulfuric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com