A simulation experiment device for welding fume diffusion and blowing ventilation control

A technology for controlling simulation and experimental devices, applied in teaching models, instruments, educational appliances, etc., can solve the problems of difficult diffusion mechanism of welding fume, inaccurate simulation results, lack of experimental comparison, etc., and achieve accurate and reliable experimental results and easy operation and use. , the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

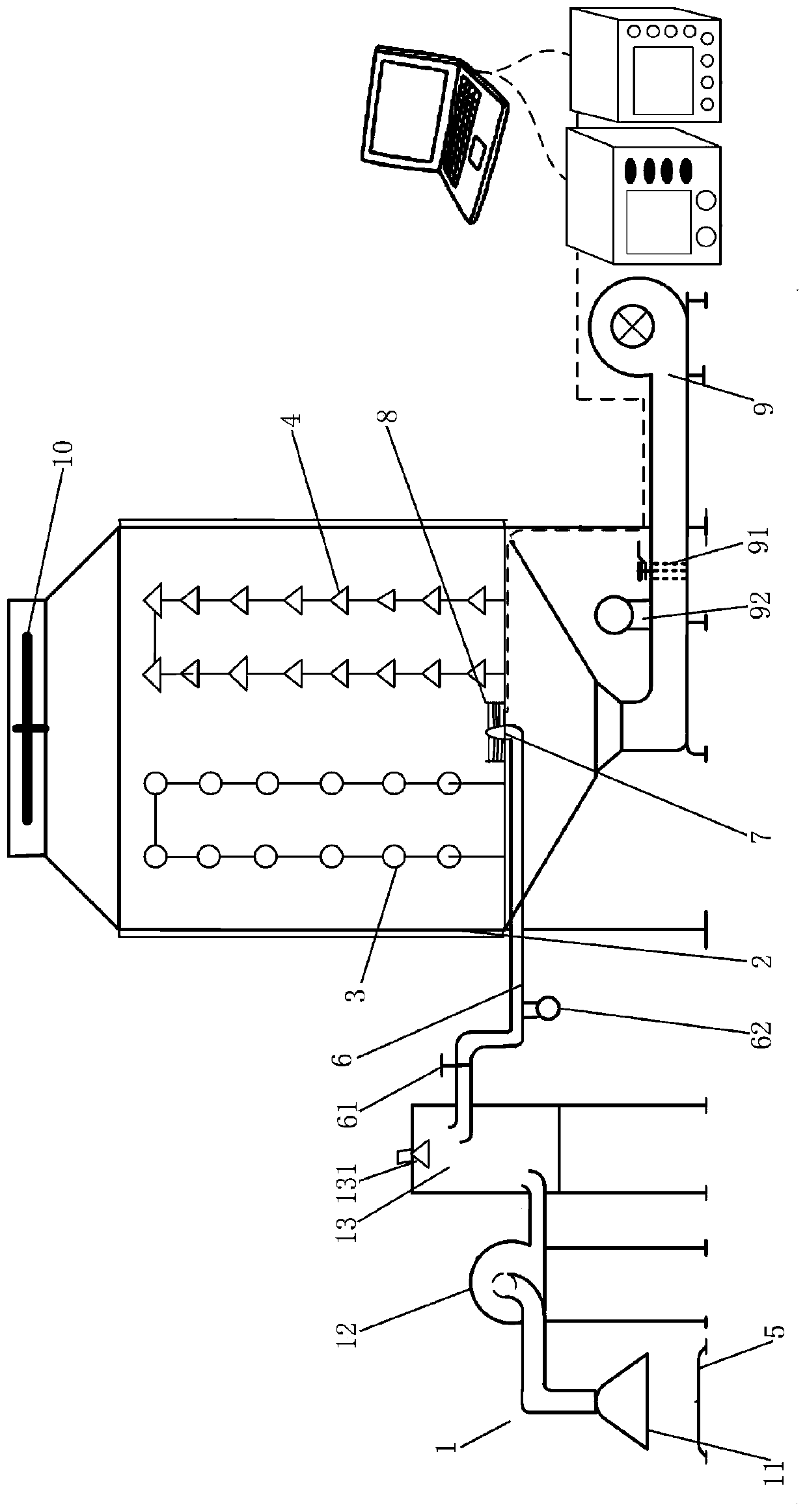

[0036] Embodiment one: if figure 1 As shown, the simulation experimental device for welding fume diffusion and blowing ventilation control in this embodiment includes a gas collection system 1, a transparent diffusion box 2, a plurality of temperature sensors 3, a plurality of gas concentration sensors 4, a data acquisition and analysis system and a blower. Suction ventilation system;

[0037] The top and the bottom of the diffusion box 2 are respectively provided with vents;

[0038] The air inlet of the above-mentioned gas collection system 1 is arranged above the above-mentioned welding platform 5 to collect electric welding fumes generated during welding of the welding platform 5;

[0039] The exhaust port of the above-mentioned gas gathering system 1 is connected with a gas delivery pipe 6;

[0040] The end of the above-mentioned gas delivery pipe 6 away from the gas-collecting system 1 passes through the side wall of the above-mentioned diffusion box 2 and extends into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com