Three-state charge capture memory based on graphene oxide quantum dots and manufacturing method thereof

A technology of graphene quantum dots and charge trapping, applied in the direction of electric solid-state devices, circuits, electrical components, etc., can solve the problems of reducing operating voltage, achieve strong information storage capabilities, stable flat-band voltage retention characteristics, and reliable device stability characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

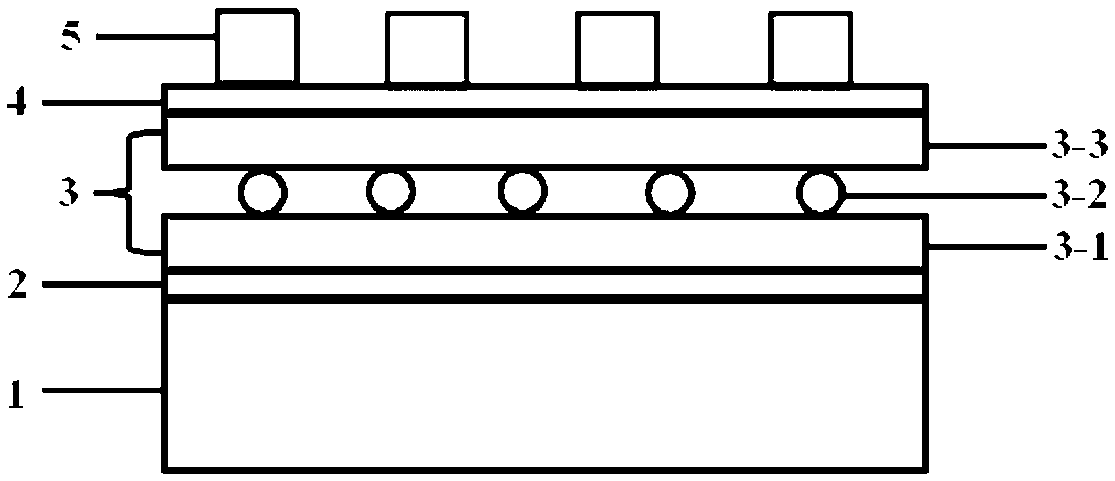

[0037] Example 1 Three-state charge trap memory based on graphene oxide quantum dots

[0038] Such as figure 2As shown, the three-state charge trapping memory based on graphene oxide quantum dots of the present invention has a structure including the bottom substrate 1, an oxide dielectric layer on the substrate 1 and an electrode film layer 5 on the oxide dielectric layer, in,

[0039] The substrate 1 is a p-type Si substrate;

[0040] The oxide dielectric layer is a composite structure of a silicon dioxide tunneling oxide layer 2, a charge trapping layer 3 and a silicon dioxide blocking oxide layer 4, wherein the charge trapping layer 3 consists of the first zinc oxide film layer 3-1, A single-layer graphene oxide quantum dot layer 3-2 and a second zinc oxide film layer 3-3 are formed; wherein, the thickness of the silicon dioxide tunneling oxide layer 2 is 2 to 5 nm, and the thickness of the silicon dioxide blocking oxide layer 4 is 5-15nm, the thickness of the first zi...

Embodiment 2

[0042] Example 2 Preparation method of triple-state charge-trap memory based on graphene oxide quantum dots

[0043] (1) Forming an oxide dielectric layer on the substrate.

[0044] ①. Selection and processing of substrate materials

[0045] Select p-type Si (100 crystal orientation) as the substrate (or substrate), put the substrate in acetone and clean it ultrasonically for 10 minutes, then put it in alcohol and clean it ultrasonically for 10 minutes, then take it out and put it in Use ultrasonic cleaning in deionized water for 5 minutes, then take it out, and use nitrogen (N 2 ) and blow dry; then soak the substrate in a hydrofluoric acid solution diluted with deionized water, take it out and clean it again with ultrasonic waves in deionized water for 5 minutes, and then take it out with N 2 Blow dry to clean the treated Si substrate.

[0046] ② Growth of silicon dioxide tunneling oxide layer

[0047] Fix the cleaned Si substrate in a rapid thermal oxidation furnace. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com