Overcurrent protection driving circuit and electric vehicle motor controller

An overcurrent protection and drive circuit technology, applied in electrical components, electronic switches, pulse technology, etc., can solve the problems of large drive circuit, cumbersome circuit, complex circuit structure, etc., to achieve sensitive overcurrent protection, simple circuit, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

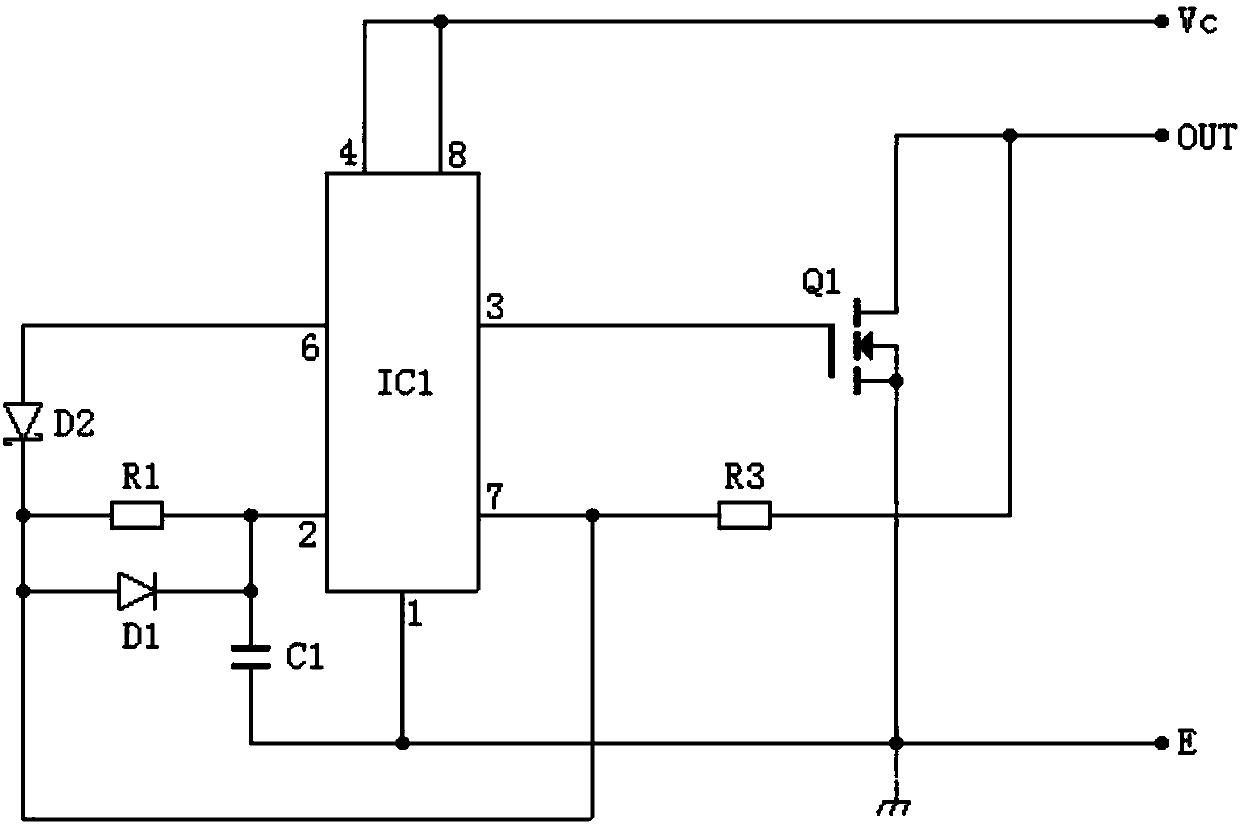

Embodiment 1

[0026] Such as figure 1 As shown, the structural features of this circuit include time base circuit IC1, timing capacitor C1, first resistor R1, first diode D1, first voltage regulator tube D2 or second resistor R2, third resistor R3, power Tube Q1, the negative pole (1) of the power supply of the time base circuit is grounded, the positive pole (8) of the time base circuit is connected to the positive pole Vc of the power supply, the zero clearing terminal (4) of the time base circuit is connected to the external control signal or the positive pole Vc of the power supply, the time base circuit The output end (3) of the power tube Q1 is connected to the input end of the power transistor, the low trigger end (2) of the time base circuit is connected to one end of the timing capacitor C1, one end of the first resistor R1, and the negative pole of the first diode D1 at the same time, and the timing capacitor The other end of C1 is grounded E, the other end of the first resistor R...

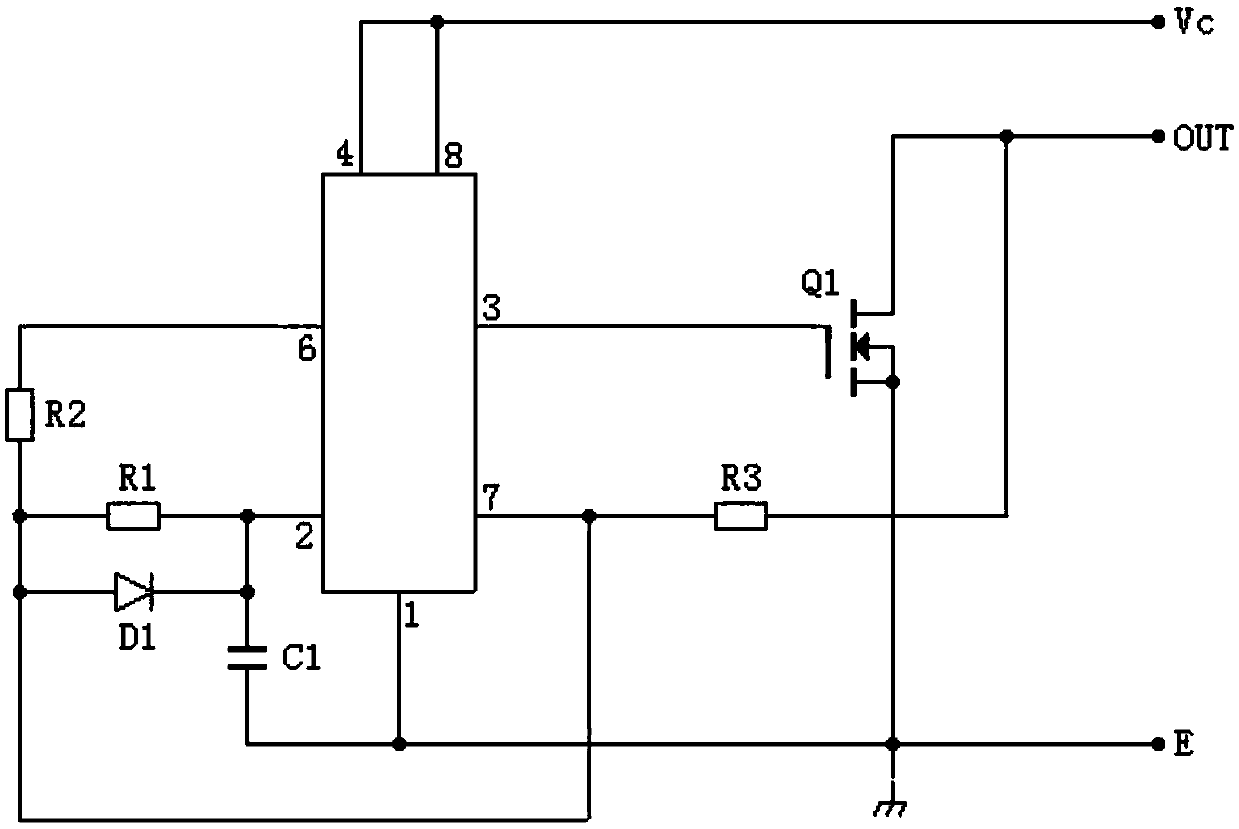

Embodiment 2

[0034] Such as figure 2 As shown, the time base circuit is a 555 integrated chip. This circuit is the same as the aforementioned figure 2 In comparison, the voltage regulator tube D2 is replaced by the resistor R2, which can also serve as the drain voltage when the power tube is overvoltage passed through R3.

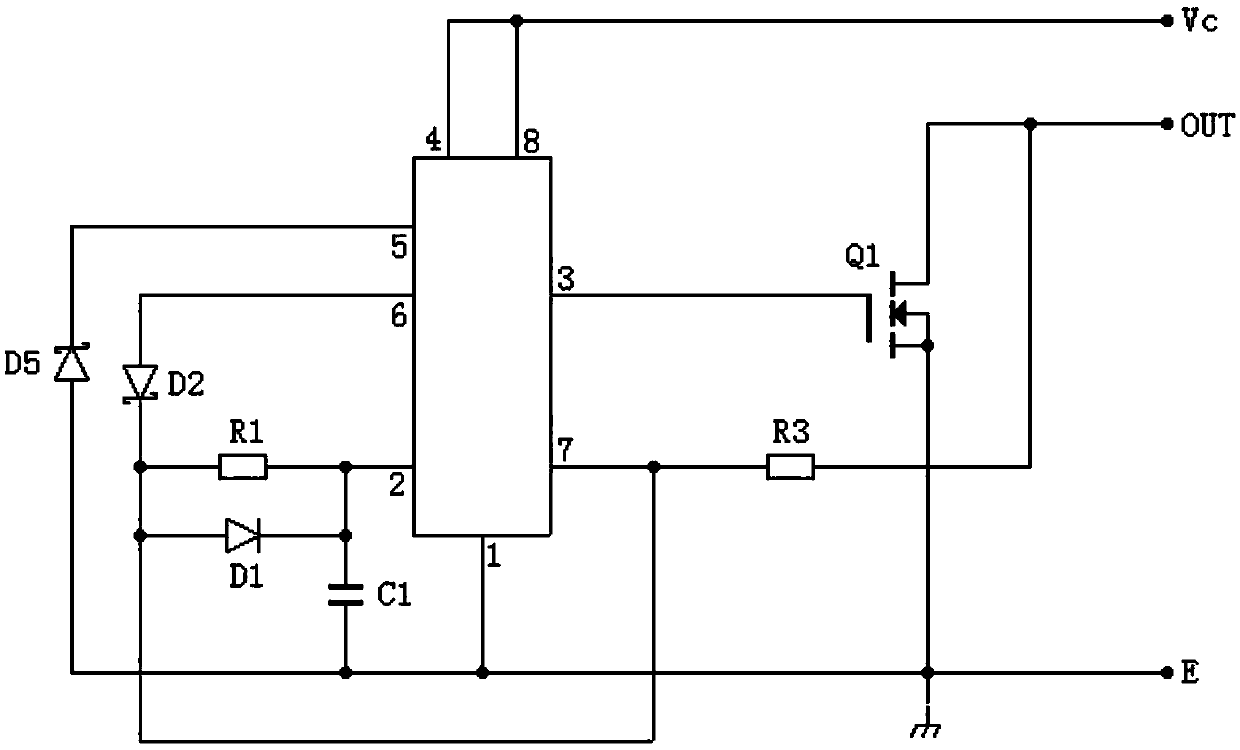

Embodiment 3

[0036] Such as image 3 As shown, the structural feature of this circuit is that the threshold terminal 5 of the time base circuit is connected to the ground with a Zener diode D5. Since the charging upper limit of the capacitor C1 is adjusted, when the stabilized voltage value of D5 is lower than the high trigger threshold voltage inside the chip , the sensitivity of the overcurrent protection action is improved, and the voltage regulation value of D5 is reduced, and the starting current value of the overcurrent protection will be reduced, and the overcurrent protection is more sensitive. You can also adjust the default time of overcurrent. When there is continuous overcurrent, a pulse of a certain oscillation frequency will appear on the drain of the power tube formed by the charging and discharging of C1. The charging time of C1 is the default time of overcurrent, and its duty cycle is generally designed It can be lower than 1%, which can be determined according to calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com