Cabbage harvester

A harvester and cabbage technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as low efficiency of cabbage, and achieve the effects of low labor intensity, compact structure and high production efficiency for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

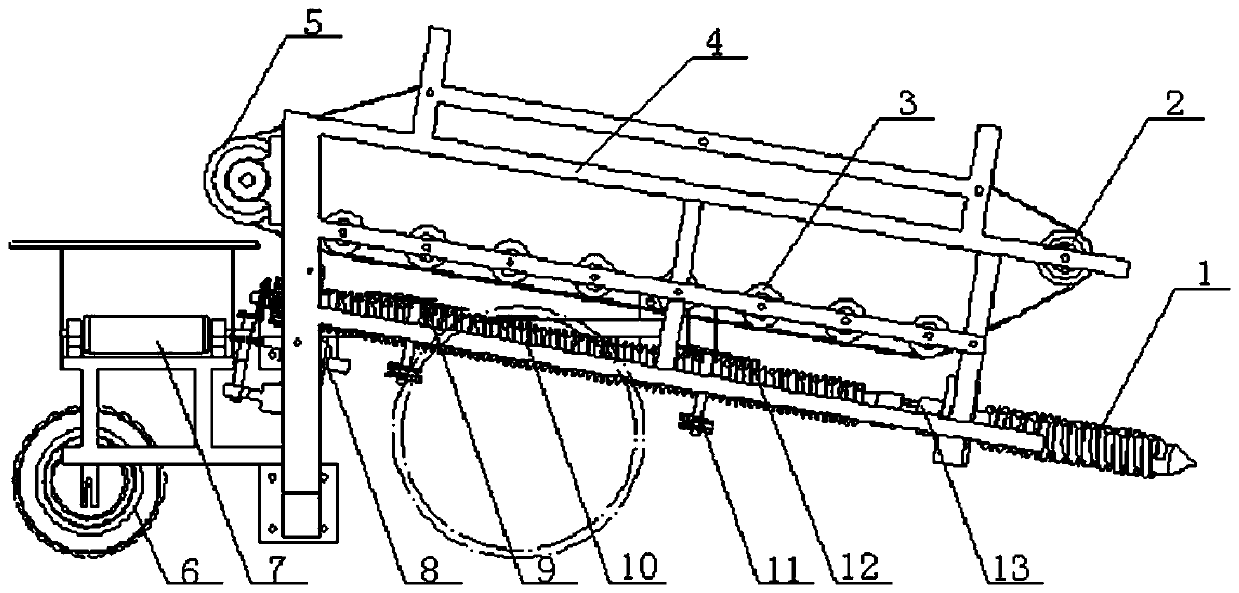

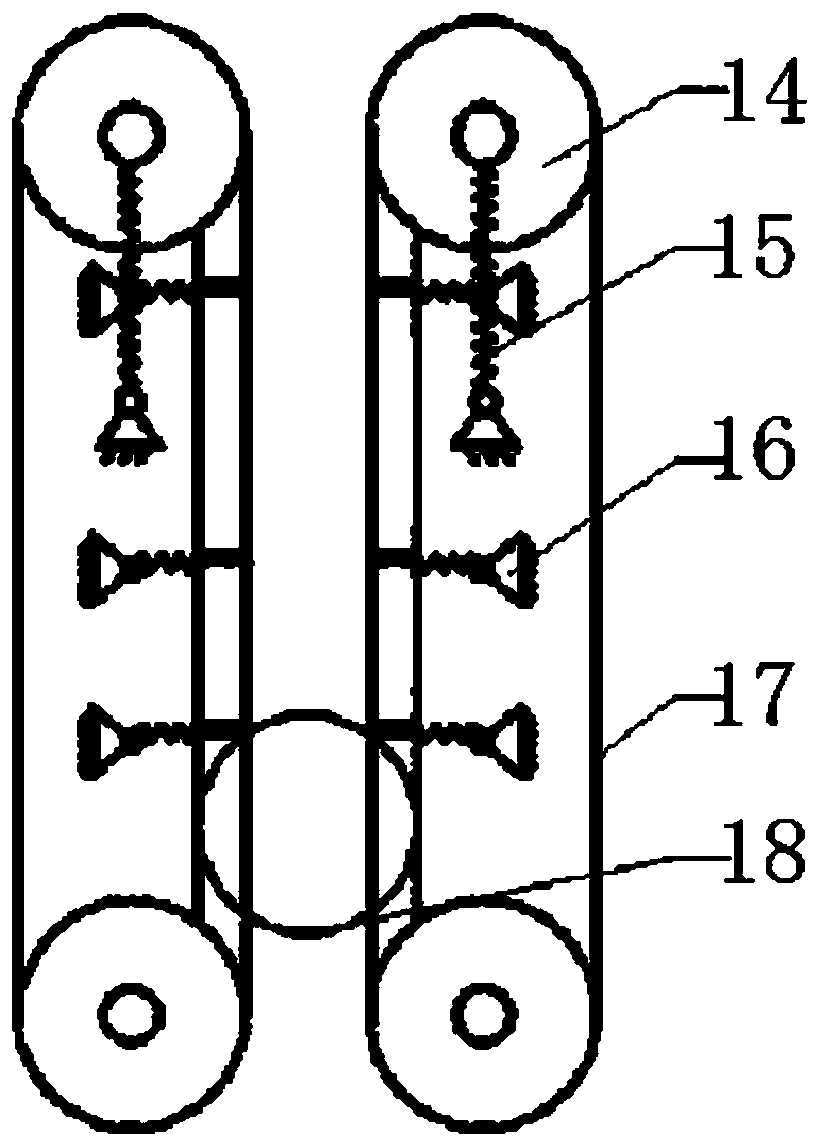

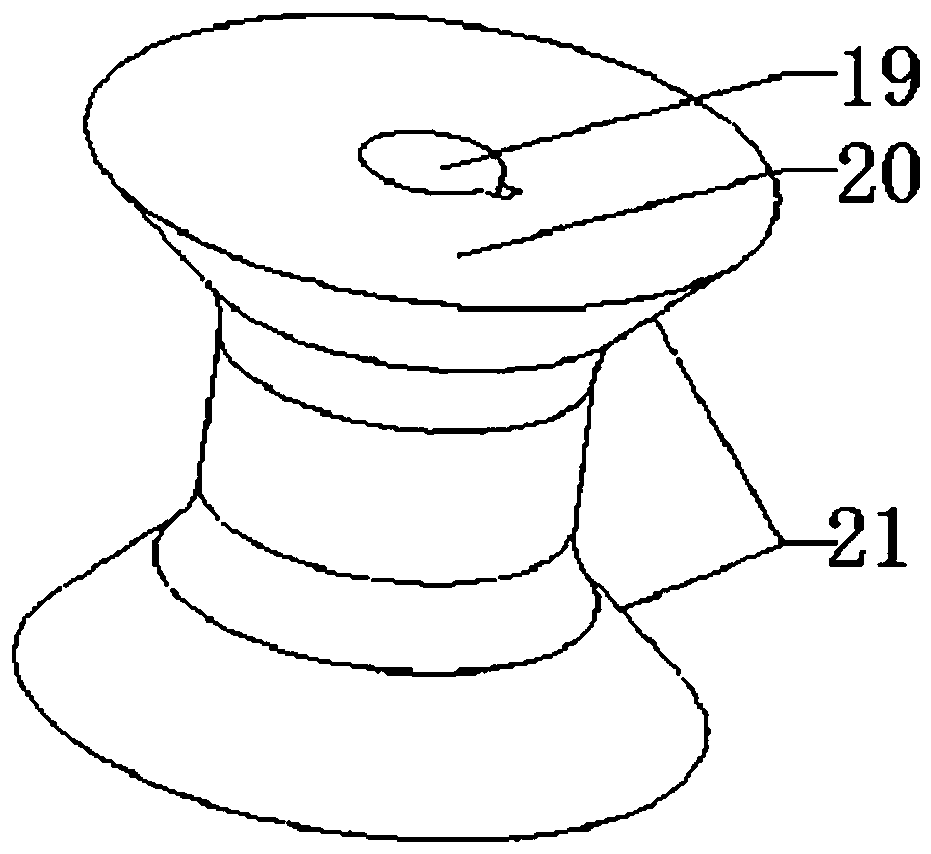

[0017] exist figure 1 Medium, including collection mechanism, front pulley, pressing device, frame, rear pulley, ground wheel, conveyor pulley, gear box, secondary cutting knife, lifting mechanism, sprocket, primary cutting knife, ball hinge universal joint , wherein the collection mechanism (1) is composed of two rotating spiral shafts at a certain angle, which play the role of collecting and pulling out cabbage; the lifting mechanism (10) is composed of two parallel spiral shafts, using cabbage root and The frictional force generated at the contact point of the screw shaft transports the cabbage to the cutter for cutting, and finally transports the cabbage with cut rotten leaves out of the lifting device; The cabbage is righted, which is convenient for the screw conveyor to transport the cabbage and provides auxiliary force for cutting the cabbage root. The cutting device is composed of two pairs of cutting knives. The first cutting knife (12) roughly cuts off a part of cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com