Flexible electrode array-optical fiber composite neutral electrode and its preparation method

A flexible electrode and composite nerve technology, applied in the fields of neuroscience and bio-instrument engineering, can solve the problems of spatial accuracy and mechanical performance limitations, and achieve the effect of reducing damage and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Fabrication of Flexible Electrode Arrays

[0068] 1. Electrode design;

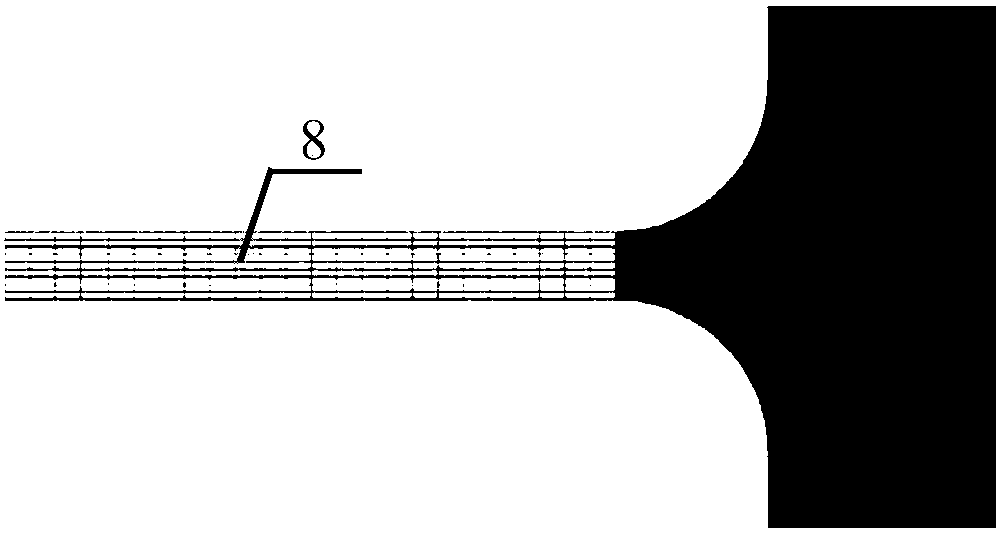

[0069] (1) Mesh electrodes:

[0070] Solder joints: rectangular, 2mm long, 0.7mm wide, 1mm apart, 10 channels evenly arranged.

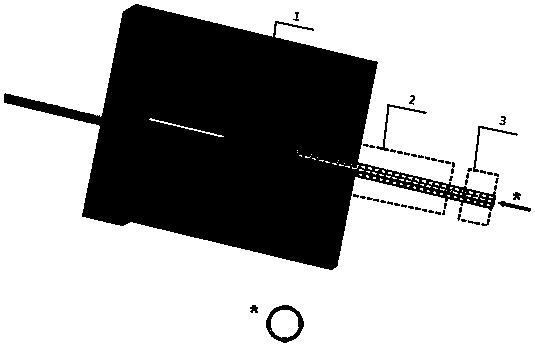

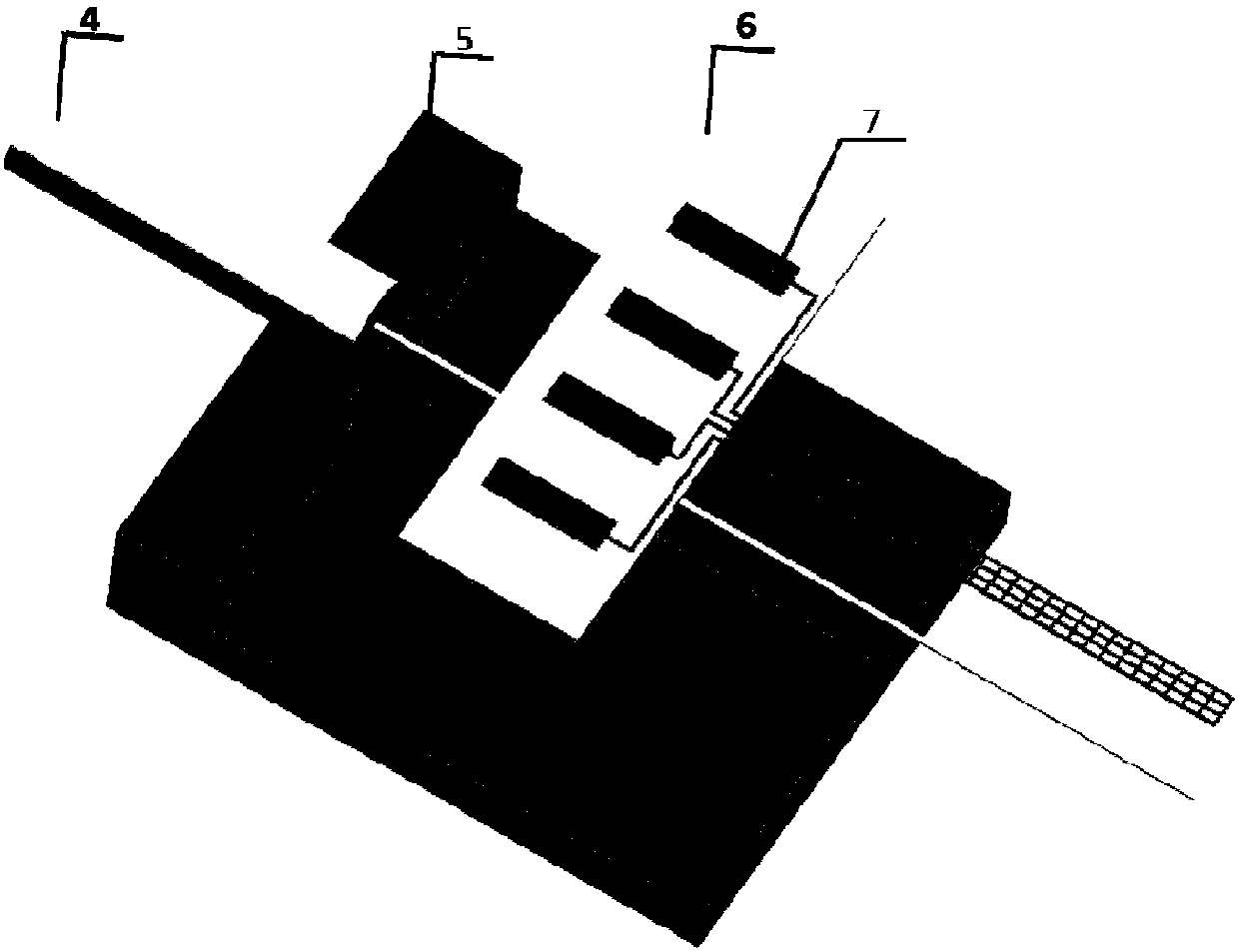

[0071] Recording site: circular, 30 μm in diameter, see Figure 4 for the arrangement.

[0072] Substrate layer SU8-1 layer: thickness 5 μm, horizontal stripe width 20 μm, length 1.115 mm, spacing 500 μm; vertical stripe width 35 μm, length 15 mm. The electrode longitudinal strip and the cable part are connected by an arc to avoid stress concentration.

[0073] Conductive layer Au layer: The width of the conductive Au line is 15 μm, the thickness is 100 nm, and the thickness of the Cr layer of the adhesion layer is 5 nm.

[0074] Insulation layer SU8-2 layer: thickness 0.5μm, the difference from SU8-1 lies in the following points, the disc electrode with a diameter of 30μm at the recording site is exposed, the first channel and the tenth channel are completely exposed ...

Embodiment 2

[0114] 3D printing support structure

[0115] Design the three-dimensional graphics of the support structure on the PROE three-dimensional graphic design software; the size parameters are as follows: the length of the support structure is 18 mm; the width of the support structure is 15 mm; the thickness of the support structure is 1 mm; the aperture of the support structure is 2.40 mm; save as . STL format.

[0116] On the CoLiDo 3D printer supporting software Print-Rite Repetier-Host, adjust the material parameters and the location and method of printing, click to automatically generate the Slic3r code, save it in the .GCO format to the printer’s supporting memory card, and start printing.

Embodiment 3

[0118] Flexible electrode array / optical fiber composite nerve electrode

[0119] The size of the optical fiber used in the present invention is as follows: Fiber core

[0120] Assemble the optical fiber and the optical fiber support, then place the electrode on the optical fiber support, pay attention to center the optical fiber and the electrode position left and right, so that the electrode is about 0.5mm beyond the optical fiber; then put it into deionized water, pull it out vertically, and curl the electrode into a package Cover the surface of the optical fiber, then put the flexible electrode array / fiber composite nerve electrode into the cured material melted at high temperature for curing, and finally fix the electrode and the supporting structure with copper tape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com