Optimization design method of blunt trailing edge airfoil under condition of surface roughness of wind turbine blade

A technology for wind turbine blades and rough surface is applied in the field of airfoil optimization design and modification to achieve the effects of improving aerodynamic performance, improving wind energy utilization, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

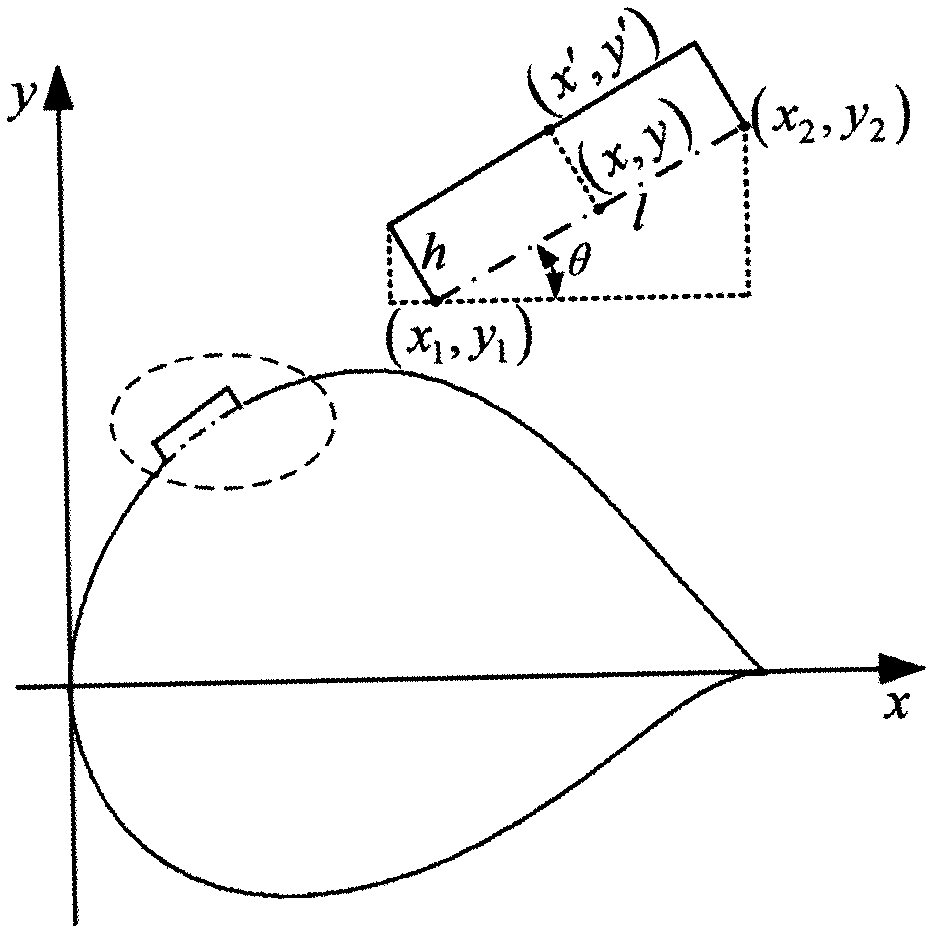

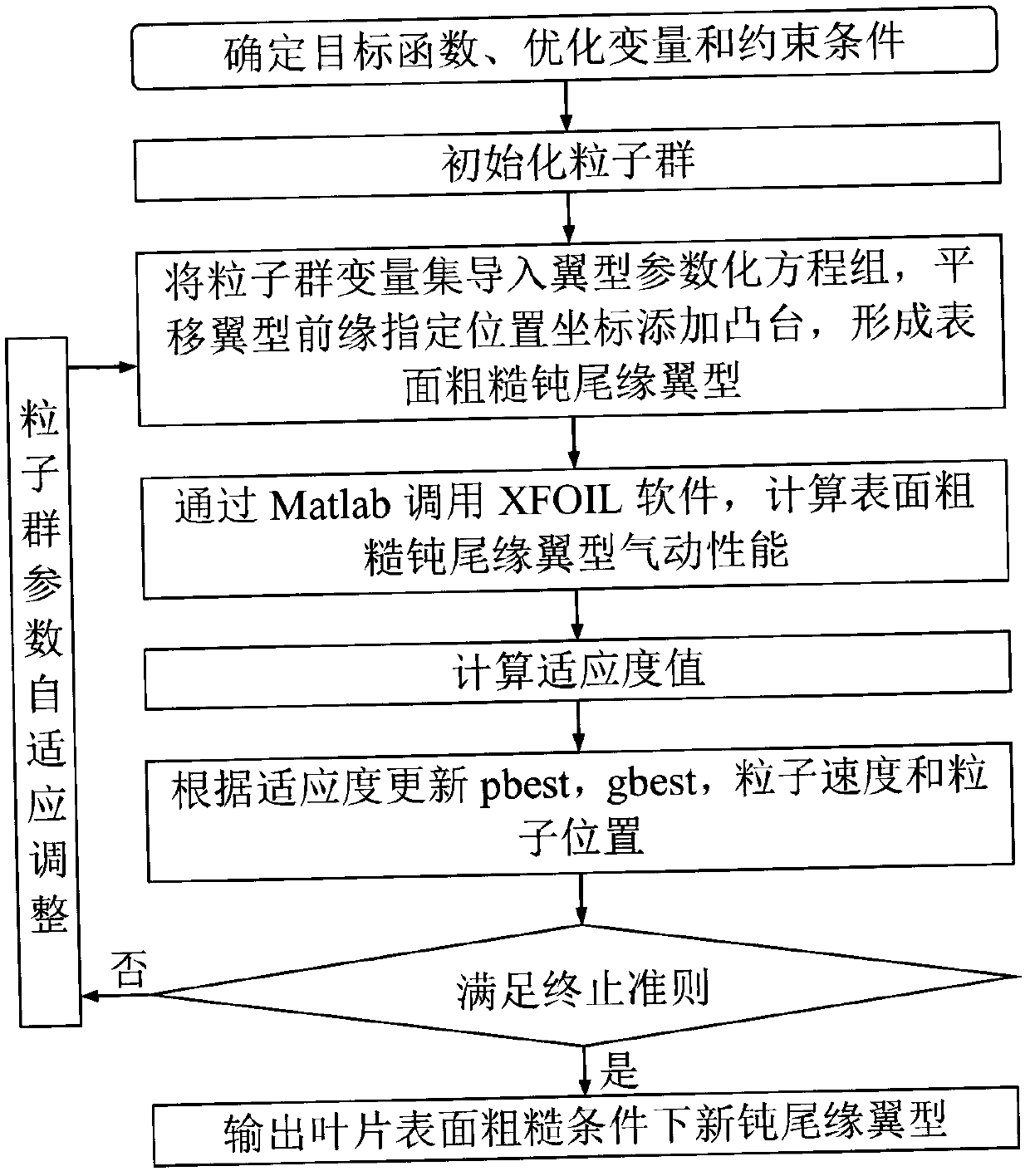

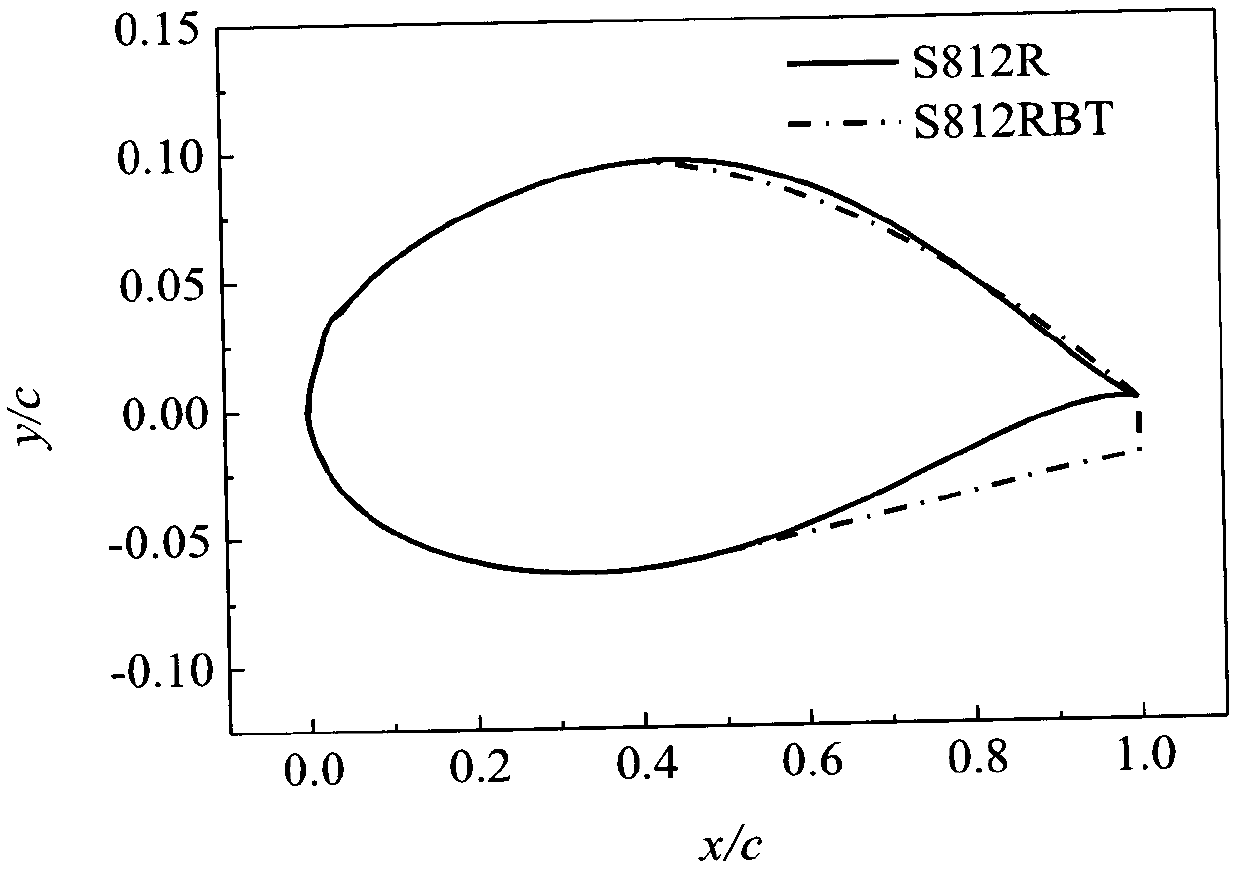

[0086] 1. The S822 airfoil is widely used in the main power generation area of wind turbine blades, with a maximum relative thickness of 16% at 39.2%c, and a maximum relative camber of 1.92% at 59.5%c; on the upper surface of the airfoil 2%c Add a boss with height h=0.003c and width l=3mm.

[0087] 2. Optimizing the initial conditions is: take the Reynolds number Re as 5×10 5 , the Mach number Ma is 0.11, the population size is 20, the maximum evolutionary generation is 300 generations, and the learning factor S 1 , S 2 is 0.5, and the variable dimension is 20; in order to make the algorithm program have both strong search ability and good convergence, the inertia weight w adopts the linear reduction adaptive adjustment formula:

[0088]

[0089] In the formula, w max and w min Indicates the maximum and minimum values of inertia weight, 0.9 and 0.4 are selected according to design experience; t and t max Indicates the current and maximum evolutionary generations.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com