Crank slider type forestry trimming head

A crank-slider type, trimming head technology, applied in agriculture, agricultural machinery and tools, cutting tools, etc., can solve the problems of poor shearing effect and high cost of the shearing head, and achieve good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

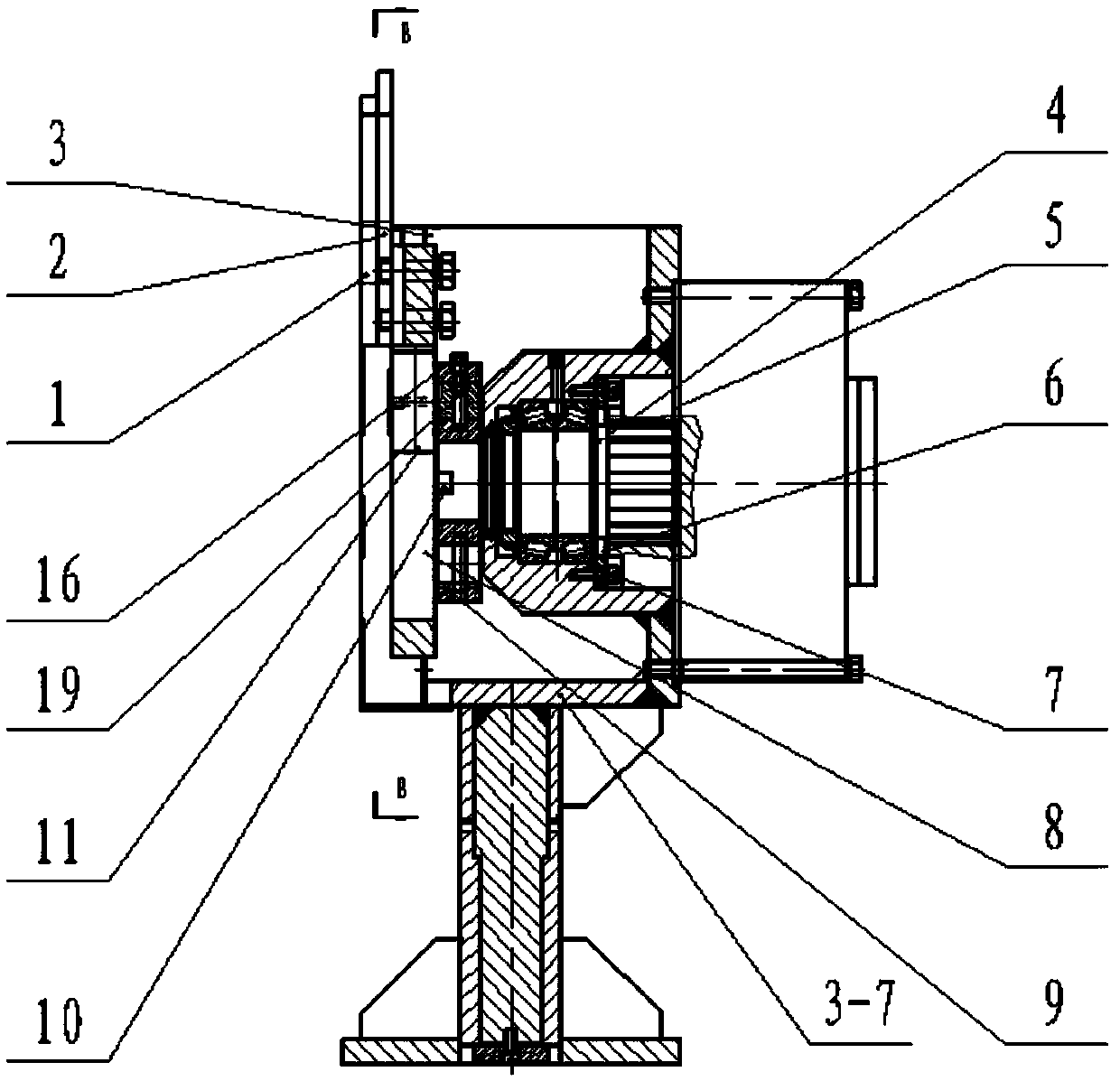

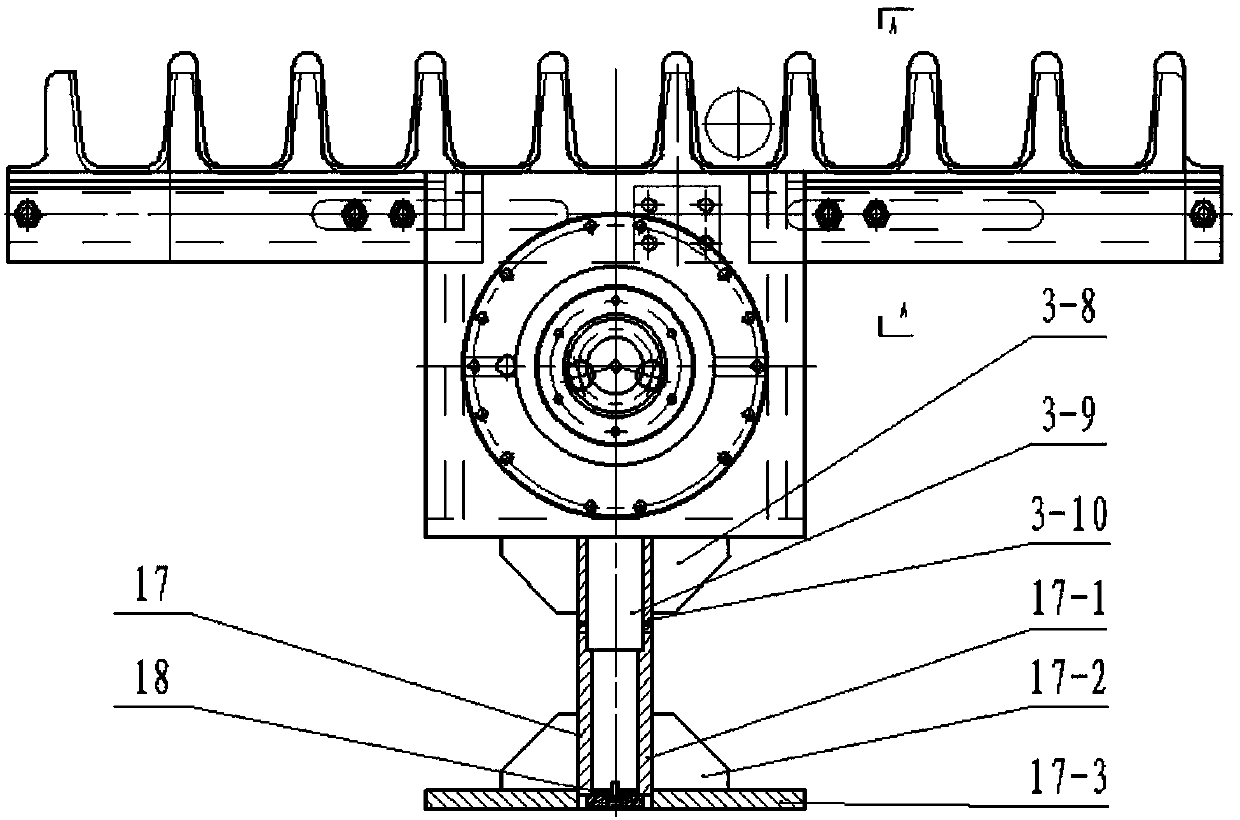

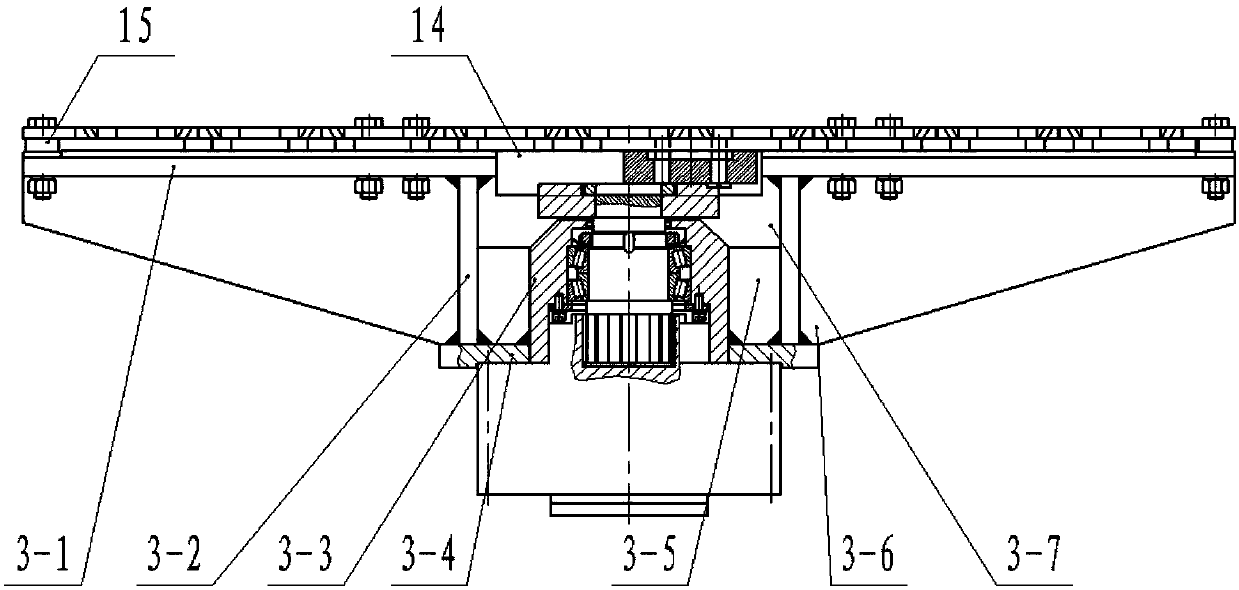

[0016] like Figure 1 to Figure 5 As shown, a crank slider type forestry pruning head in this embodiment includes a fixed cutting edge 1, a moving cutting edge 2, a knife seat 3, a spline shaft 4, a motor 5, a transparent cover 6, and a roller bearing 7 , slide plate 8, turntable 9, turntable cover 10, bearing slider 11, copper plate 12, guide slide plate 13, pad 15, screw plug 16, connection seat 17, block cover 18 and pin 19; And the guide slide plate 13 is fixed on the cutting edge support plate 3-1 of the knife seat 3 by bolts and the guide slide plate 13 is located between the fixed shear edge 1 and the shear edge support plate 3-1, and the movable shear edge 2 is installed on the fixed shear edge 1 Between the blade support plate 3-1 and the slide guide plate 13 located in the sliding groove provided at the lower part of the movable she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com