Method for preparing novel antibacterial material

An antibacterial material and a new type of technology, applied in the field of preparation of new antibacterial materials, can solve the problems of unsatisfactory antibacterial properties of antibacterial materials, and achieve the effects of green environmental protection, improved antibacterial stability, and improved biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

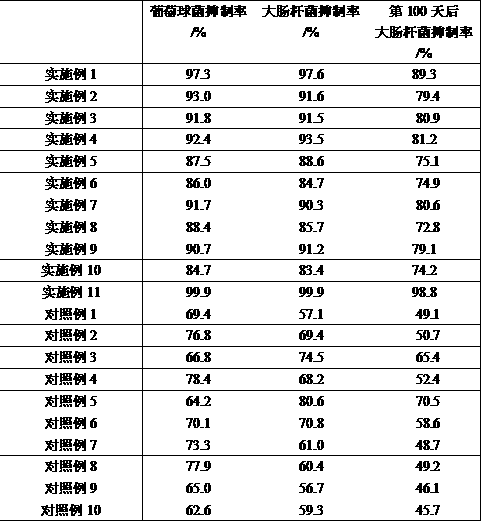

Examples

Embodiment 1

[0017] A kind of preparation method of novel antibacterial material, this method comprises the following steps:

[0018] Step 1, 65 parts of polyethylene, 13 parts of Cu-MOF-Al 2 o 3 Nanomaterials, 3 parts of ethyl formate and 5 parts of polylactic acid were added to the reactor, and 1 part of sodium carbonate, 5 parts of lauryl betaine, 1 part of sodium tripolyphosphate and 0.8 parts of sodium xylene sulfonate were dissolved in 30 parts water, then add it into the reaction kettle, stir and mix evenly under the condition of 50°C, the stirring speed of stirring and mixing is 150 rpm, and the mixing time is 30 minutes, then raise the temperature to 80°C under the vacuum degree of 0.01MPa, stir After 20 minutes, the temperature was raised to 130° C., and the reaction was stirred for 30 minutes to obtain the initial product;

[0019] Step 2. Add 1.5 parts of antioxidant BHT and 1.3 parts of co-antioxidant DLTP to the primary product obtained in step 1, stir and mix evenly at a t...

Embodiment 2

[0029] Step 1, 50 parts of polyethylene, 16 parts of Cu-MOF-Al 2 o 3 Nanomaterials, 4 parts of ethyl formate and 5 parts of polylactic acid were added to the reaction kettle, and 1 part of sodium carbonate, 5 parts of lauryl betaine, 1 part of sodium tripolyphosphate and 0.8 parts of sodium xylene sulfonate were dissolved in 30 parts water, then add it into the reaction kettle, stir and mix evenly under the condition of 50°C, the stirring speed of stirring and mixing is 150 rpm, and the mixing time is 30 minutes, then raise the temperature to 80°C under the vacuum degree of 0.01MPa, stir After 20 minutes, the temperature was raised to 130° C., and the reaction was stirred for 30 minutes to obtain the initial product;

[0030] All the other preparations are the same as in Example 1.

Embodiment 3

[0032] Step 1, step 1, 45 parts of polyethylene, 23 parts of Cu-MOF-Al 2 o 3 Nanomaterials, 6 parts of ethyl formate and 5 parts of polylactic acid were added to the reactor, and 1 part of sodium carbonate, 5 parts of lauryl betaine, 1 part of sodium tripolyphosphate and 0.8 parts of sodium xylene sulfonate were dissolved in 30 parts water, then add it into the reaction kettle, stir and mix evenly under the condition of 50°C, the stirring speed of stirring and mixing is 150 rpm, and the mixing time is 30 minutes, then raise the temperature to 80°C under the vacuum degree of 0.01MPa, stir After 20 minutes, the temperature was raised to 130° C., and the reaction was stirred for 30 minutes to obtain the initial product;

[0033] All the other preparations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com