Antibacterial fiber fabric and preparation method thereof

A fabric and fiber technology, which is applied in the field of antibacterial fiber fabrics and their preparation, can solve the problems that the washing fastness and performance stability of antibacterial fabrics need to be further improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

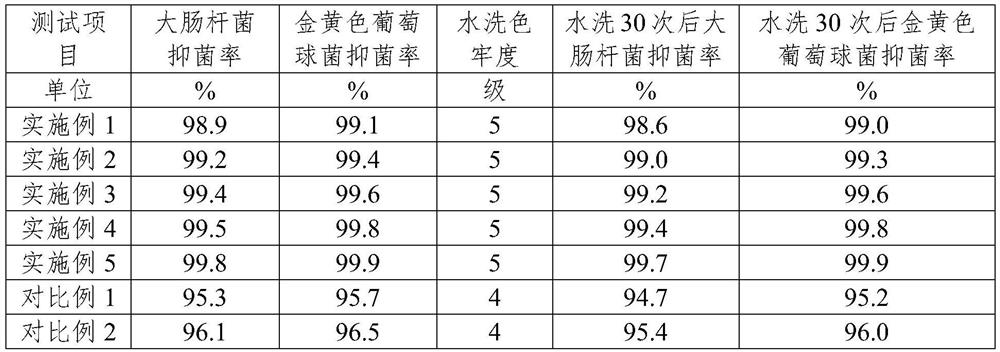

Examples

preparation example Construction

[0028] Preferably, the (2-methyl-1-vinylimidazole)-(2-allyl-1,2-benzisothiazol-3(2H)-one 1,1-dioxide)-ene The preparation method of propylthiourea copolymer comprises the steps of: 2-methyl-1-vinylimidazole, 2-allyl-1,2-benzisothiazol-3(2H)-ketone 1,1 - Dioxide, allylthiourea, and initiator are added to the high-boiling solvent, stirred and reacted at 65-75°C for 3-5 hours in an inert gas atmosphere, and then precipitated in water, and the precipitated polymer Wash with ethanol for 3-6 times, then dry in a vacuum oven at 85-95°C to constant weight to obtain (2-methyl-1-vinylimidazole)-(2-allyl-1,2-benzene and isothiazol-3(2H)-one 1,1-dioxide)-allylthiourea copolymer.

[0029] Preferably, the 2-methyl-1-vinylimidazole, 2-allyl-1,2-benzisothiazol-3(2H)-one 1,1-dioxide, allylthiourea , Initiator, the mass ratio of high boiling point solvent is (1-2): 3: (0.8-1.2): (0.05-0.08): (20-30).

[0030] Preferably, the initiator is at least one of azobisisobutyronitrile and azobisisohe...

Embodiment 1

[0043] This example provides a kind of antibacterial fiber fabric, it is characterized in that, described antibacterial fiber fabric is made of polyester silk, antibacterial fiber silk, milk protein fiber silk through blending and weaving; The weight of described antibacterial fiber silk in fabric The percentage content is 25wt%, and the weight percentage content of the milk protein fiber silk in the fabric is 10wt%; the antibacterial fiber silk is made by the solution composite spinning method of the following components in parts by weight: (2- Methyl-1-vinylimidazole)-(2-allyl-1,2-benzisothiazol-3(2H)-one 1,1-dioxide)-allylthiourea copolymer 60 parts , 3 parts of bamboo charcoal powder, 8 parts of nano silver powder, 2 parts of coupling agent.

[0044] The fineness of the antibacterial fiber silk is 150D, the fineness of the polyester silk is 60D; the fineness of the milk protein fiber silk is 50D; the coupling agent is a silane coupling agent KH550; the particle diameter of...

Embodiment 2

[0055] This example provides an antibacterial fiber fabric and a preparation method thereof, which are basically the same as in Example 1, except that the weight percentage content of the antibacterial fiber silk in the fabric is 28wt%, and the milk protein fiber silk is in the fabric The weight percent content is 11wt%; the antibacterial fiber silk is made by the following components by weight parts through solution composite spinning method: (2-methyl-1-vinylimidazole)-(2-ene Propyl-1,2-benzisothiazol-3(2H)-one 1,1-dioxide)-allylthiourea copolymer 65 parts, bamboo charcoal powder 4 parts, nano silver powder 10 parts, coupling agent 2.5 servings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com