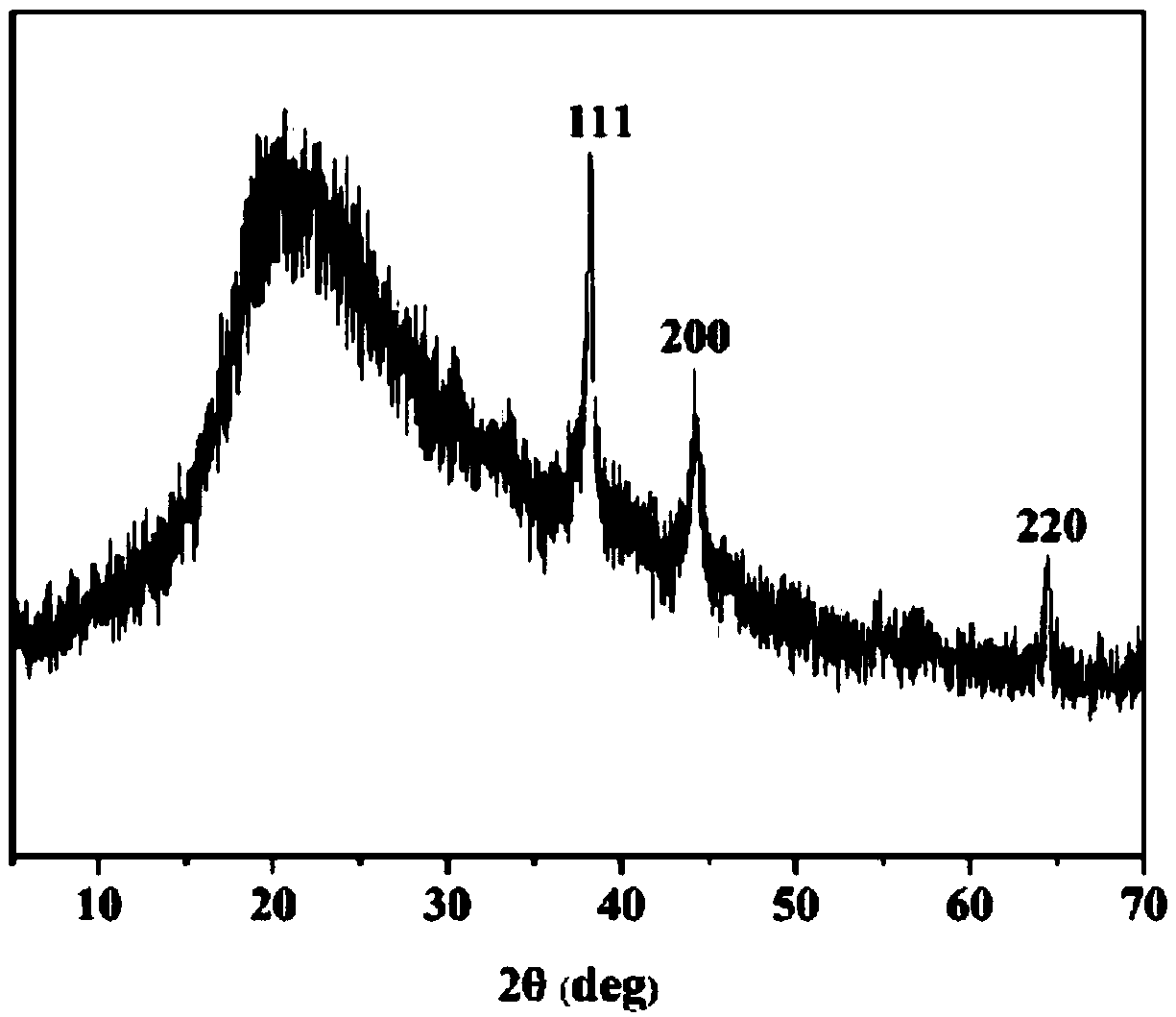

A kind of nano-silver antibacterial material and preparation method thereof

A nano-silver antibacterial and nano-silver particle technology, which is applied to nano-silver antibacterial materials and the preparation field of the above-mentioned nano-silver antibacterial materials, can solve problems such as the preparation process of nano-silver composite materials and the limited mechanical strength of nano-silver composite materials, and achieve Improved antibacterial stability, less environmental impact, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] By weight, the nano-silver antibacterial material of the present embodiment comprises the following components:

[0039]

[0040] The preparation method of nano-silver antibacterial material in the present embodiment comprises the following steps:

[0041] (1) Preparation of Dialdehyde Sodium Alginate

[0042] Dissolve sodium alginate and sodium periodate in deionized water at a weight ratio of 1:0.1, and react in the dark for 6 hours at room temperature. The product is precipitated with ethanol, washed and dried in a vacuum environment at 35°C to obtain dialdehyde alginic acid sodium;

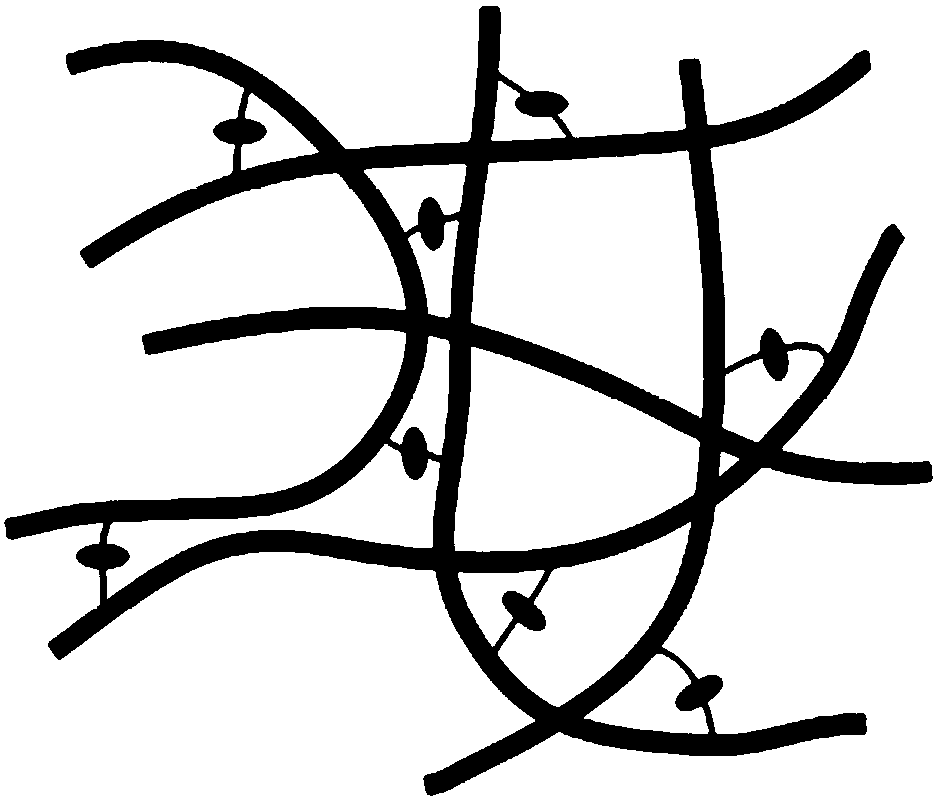

[0043] (2) Preparation of nano-silver particles-dialdehyde sodium alginate-casein composite material

[0044] Dissolve dialdehyde sodium alginate, casein, and silver nitrate in deionized water, and stir evenly to form a premixed solution. During this process, dialdehyde sodium alginate and casein undergo a cross-linking reaction, and at the same time, silver ions are The premixed ...

Embodiment 2

[0053] By weight, the nano-silver antibacterial material of the present embodiment comprises the following components:

[0054]

[0055] The preparation method of nano-silver antibacterial material in the present embodiment comprises the following steps:

[0056] (1) Preparation of Dialdehyde Sodium Alginate

[0057] Dissolve sodium alginate and sodium periodate in deionized water at a weight ratio of 1:0.5, and react in the dark for 24 hours at room temperature. The product is precipitated with acetone, washed and dried in a vacuum environment at 50°C to obtain dialdehyde alginic acid sodium;

[0058] (2) Preparation of nano-silver particles-dialdehyde sodium alginate-casein composite material

[0059] Dissolve dialdehyde sodium alginate, casein, and silver nitrate in deionized water, and stir evenly to form a premixed solution. During this process, dialdehyde sodium alginate and casein undergo a cross-linking reaction, and at the same time, silver ions are The premixed...

Embodiment 3

[0067] By weight, the nano-silver antibacterial material of the present embodiment comprises the following components:

[0068]

[0069]

[0070] The preparation method of nano-silver antibacterial material in the present embodiment comprises the following steps:

[0071] (1) Preparation of Dialdehyde Sodium Alginate

[0072] Dissolve sodium alginate and sodium periodate in deionized water at a weight ratio of 1:0.3, and react in the dark for 10 hours at room temperature. The product is precipitated with ether, washed and dried in a vacuum environment at 45°C to obtain dialdehyde alginic acid sodium;

[0073] (2) Preparation of nano-silver particles-dialdehyde sodium alginate-casein composite material

[0074] Dissolve dialdehyde sodium alginate, casein, and silver nitrate in deionized water, and stir evenly to form a premixed solution. During this process, dialdehyde sodium alginate and casein undergo a cross-linking reaction, and at the same time, silver ions are Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com