Preparation method of bacteriostatic paper

A quality and mixture technology, applied in papermaking, wrapping paper, wrapping paper, etc., can solve the problem of poor antibacterial persistence, and achieve the effect of enhancing antibacterial stability, lasting antibacterial effect, and improving mutual fusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

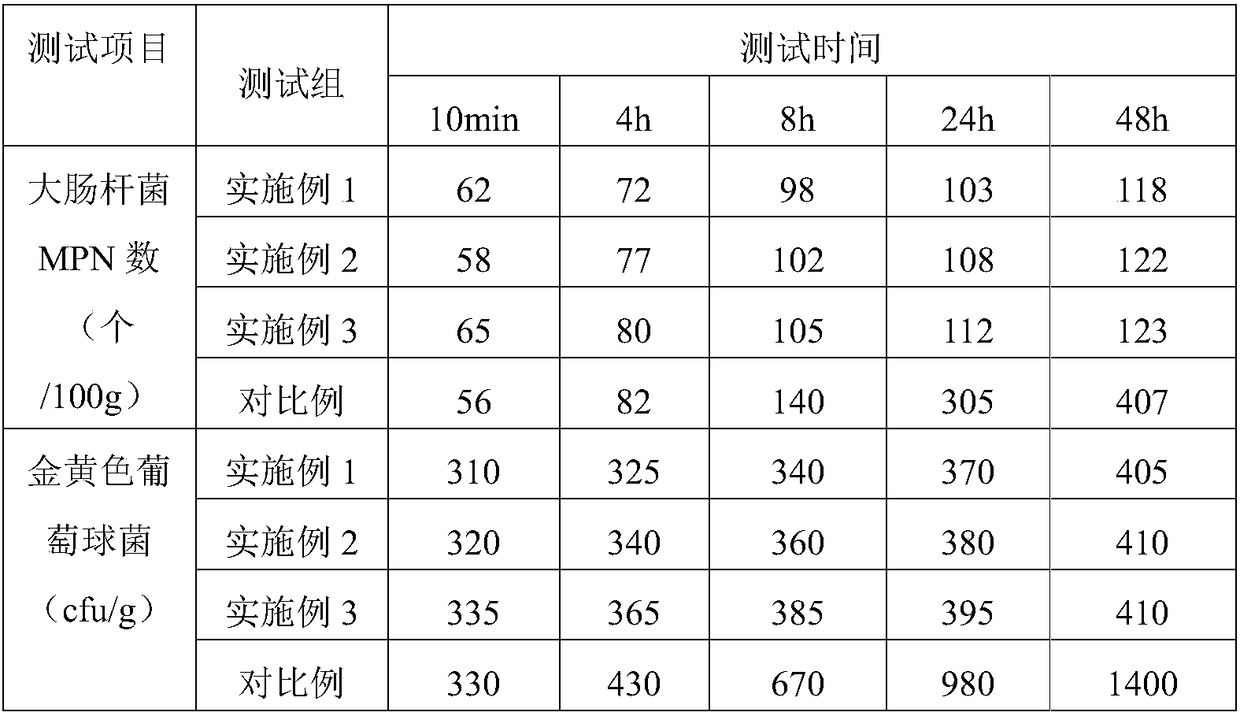

Examples

Embodiment 1

[0022] A kind of preparation method of antibacterial paper is characterized in that comprising the following steps:

[0023] (1) Pretreatment of the main fiber material: crush the natural moso bamboo to a length of 1-2 cm, add 10 times the mass of water, add a mixture of sodium salt and citric acid with a mass ratio of 4:3 at 1 g / L, and heat to 110 Keep at ℃ for 3 hours before beating; crush the bagasse to powder, add 10 times the mass of water, add a mixture of sulfite and strong alkali with a mass ratio of 1:2 at 1 g / L, maintain high temperature and high pressure for 1.5 hours, and then proceed Beating treatment: crush the maple wood to a length of 1-2 cm, add 10 times the mass of water, add a mixture of acetic acid and sodium salt with a mass ratio of 3:1 at 2 g / L, maintain high temperature and high pressure for 1.5 hours, and then perform beating treatment;

[0024] (2) Pretreatment of antibacterial Chinese herbal medicine materials: select Gentiana, Folium Isatidis, Lisia...

Embodiment 2

[0030] A kind of preparation method of antibacterial paper is characterized in that comprising the following steps:

[0031] (1) Pretreatment of fiber main material: natural moso bamboo is pulverized to 1-2cm long, adds 15 times the water of quality, adds the mixture of sodium salt and citric acid that mass ratio is 4:3 by 1.5g / L, is heated to Keep at 110°C for 3 hours before beating; crush the bagasse to powder, add 15 times the mass of water, add a mixture of sulfite and strong alkali at a mass ratio of 1:2 at 3 g / L, maintain high temperature and high pressure for 1.5 hours, and then Perform beating treatment; crush the maple wood to a length of 1-2 cm, add 15 times the mass of water, add a mixture of acetic acid and sodium salt with a mass ratio of 3:1 at 3 g / L, maintain high temperature and high pressure for 1.5 hours, and then perform beating treatment;

[0032] (2) Pretreatment of antibacterial Chinese herbal medicine materials: select Gentiana, Folium Isatidis, Lisianth...

Embodiment 3

[0038] A kind of preparation method of antibacterial paper is characterized in that comprising the following steps:

[0039] (1) Pretreatment of fiber main material: natural moso bamboo is pulverized to 1-2cm long, adds 13 times the water of quality, adds the mixture of sodium salt and citric acid that mass ratio is 4:3 by 1.2g / L, is heated to Keep at 110°C for 3 hours before beating; crush the bagasse to powder, add 13 times the mass of water, add a mixture of sulfite and strong alkali at a mass ratio of 1:2 at 2 g / L, maintain high temperature and high pressure for 1.5 hours, and then Carry out beating treatment; crush the maple wood to a length of 1-2cm, add 13 times the mass of water, add a mixture of acetic acid and sodium salt with a mass ratio of 3:1 at 2.5g / L, maintain high temperature and high pressure for 1.5h, and then perform beating treatment ;

[0040](2) Pretreatment of antibacterial Chinese herbal medicine materials: select Gentiana, Folium Folium, Lisianthus c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com