Volatile organic waste gas treatment process

A volatile organic and waste gas treatment technology, applied in the field of industrial pollutant treatment, can solve the problems of expensive absorption solvent, poor pertinence and high investment cost, and achieve the effect of wide application, low cost and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

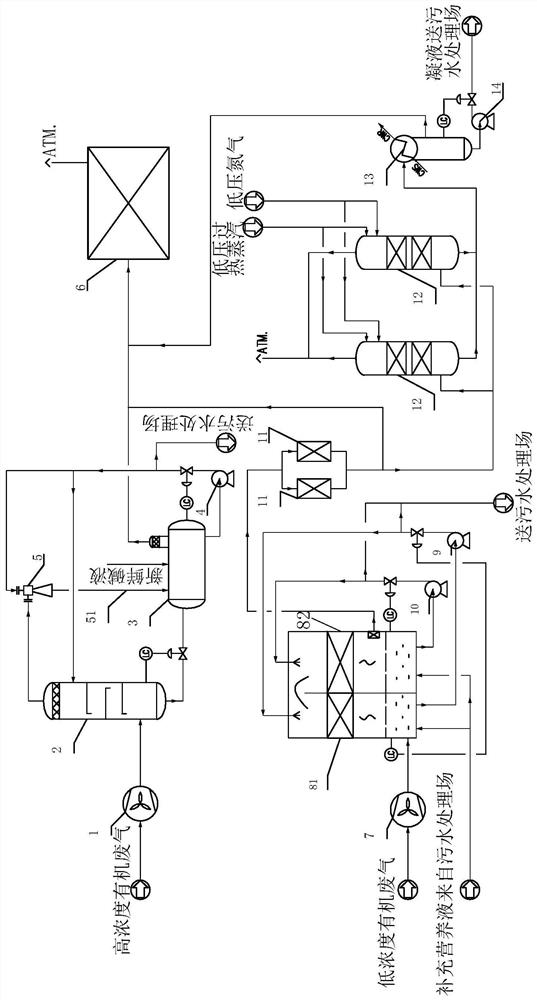

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0040] First, high-concentration volatile organic waste gases from structures such as waste water inlets, grease traps, flotation tanks, homogeneous tanks, and waste oil tanks, including sulfides, halides, ammonia nitrogen, olefins, aromatics, alkanes, and phenols After being scattered and collected by a closed gas collection hood, it is transported to a high-concentration waste gas treatment device by a pipeline.

[0041] like figure 1 As shown, under the suction of the blower 1, the temperature from the total waste water inlet, grease trap, flotation tank, homogeneous tank, sewage tank and other structures is high concentration of 25 ~ 30 ℃, pressure -20 ~ -10KPaG Volatile organic waste gas, the flow rate is 3000-6000 m 3 / h, the sulfide concentration is tens to hundreds of milligrams per cubic meter, and the total hydrocarbon concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com