A method and system for the full treatment of landfill leachate

A technology for a landfill leachate and a treatment method, which is applied in the field of a full-scale landfill leachate treatment method and a full-scale treatment system, can solve the problems of low acidity, low concentration of by-products, lack of a full-scale landfill leachate treatment process, etc. The technical advantages are obvious, the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

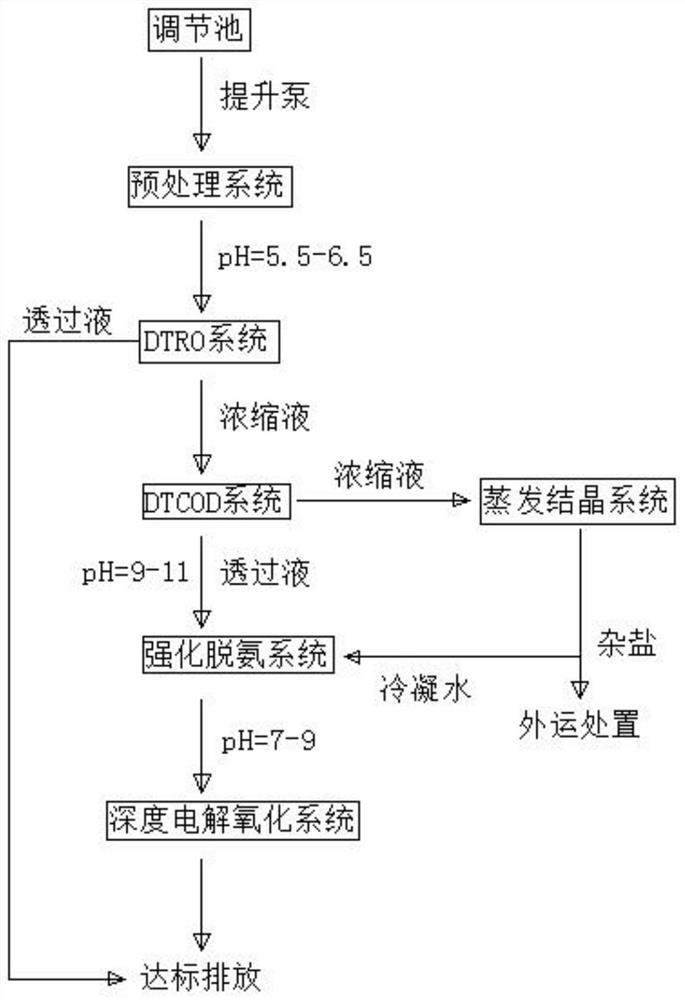

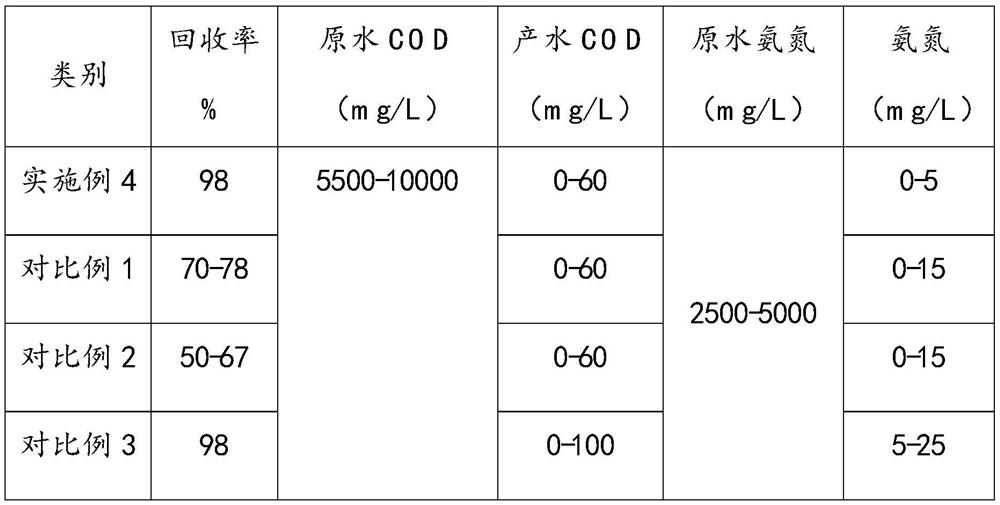

[0039] like figure 1 As shown, a landfill leachate full treatment system includes a regulating tank, the landfill leachate is connected to a pretreatment system through a lift pump, and the pretreatment system is connected to a DTRO system. The DTRO system includes a DTRO membrane module, and the inlet port of the DTRO membrane module Connect the pretreatment system, the permeate outlet of the DTRO membrane module is connected to the outlet, the concentrate outlet of the DTRO membrane module is connected to the water inlet of the DTCOD membrane treatment system, and the permeate outlet of the DTCOD membrane treatment system The terminal is connected to the enhanced deamination system, and the outlet of the concentrated solution of the DTCOD system is connected to the evaporation crystallization system. The evaporation crystallization system includes an MVR evaporation system and a drying system. The outlet of the MVR evaporation system is connected to a drying system. The syst...

Embodiment 2

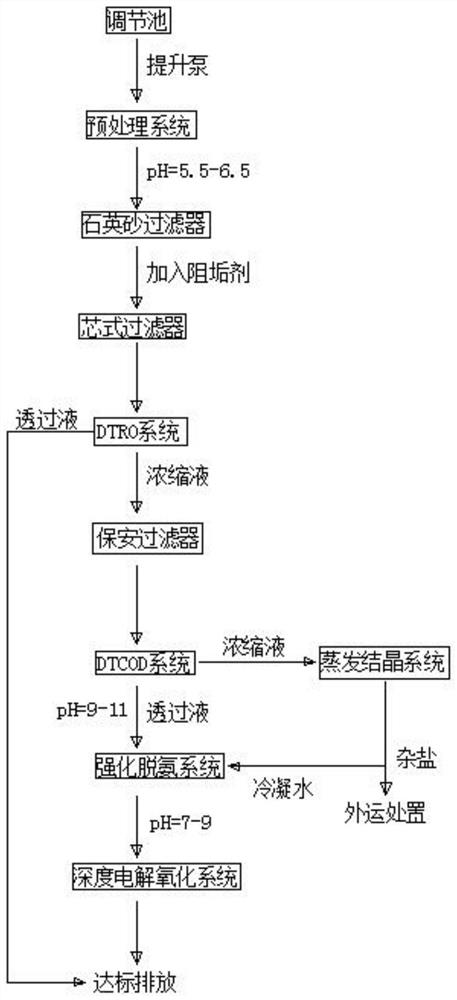

[0048] Embodiment 2 is the same as Example 1, and the difference is that in order to further realize the filtration of landfill leachate completely, when the landfill leachate is pretreated, some impurities in the landfill leachate are removed through a quartz sand filter, that is to say , the pretreatment system is connected to the quartz sand filter, and the output end of the quartz sand filter is connected to the DTRO membrane module. Further, during the filtration process of the quartz sand filter, the frequency of backwashing can be judged by the pressure difference between the inlet and outlet of the quartz sand filter. / (m 2 s), the backwash pressure is 0-0.3MPa, and the strength of backwash water is 5-20L / (m 2 ·s), the backwash water pressure is 0.15-0.3MPa. Specific parameters are adjusted according to actual needs.

[0049] The treatment process of the above landfill leachate full treatment system is as follows:

[0050] S1. The landfill leachate in the adjustmen...

Embodiment 3

[0057] Embodiment 3 is the same as Embodiment 2, the difference is that in order to further realize the high concentration of pollutants, the output end of the quartz sand filter is connected to the core filter, and the output end of the core filter is connected to the The DTRO membrane module described above. After the landfill leachate filtered through the quartz sand filter is added with antiscalant, it is first filtered through a core filter with a filtration accuracy of 5um, and then processed through the DTRO system for membrane separation. The dosing ratio of scale inhibitor is determined according to the content of sulfate and carbonate in the raw water. The preferred mass ratio is carbonate and sulfate: scale inhibitor = 7-14:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com