Acid Separation and Concentration Method in Sewage Acid

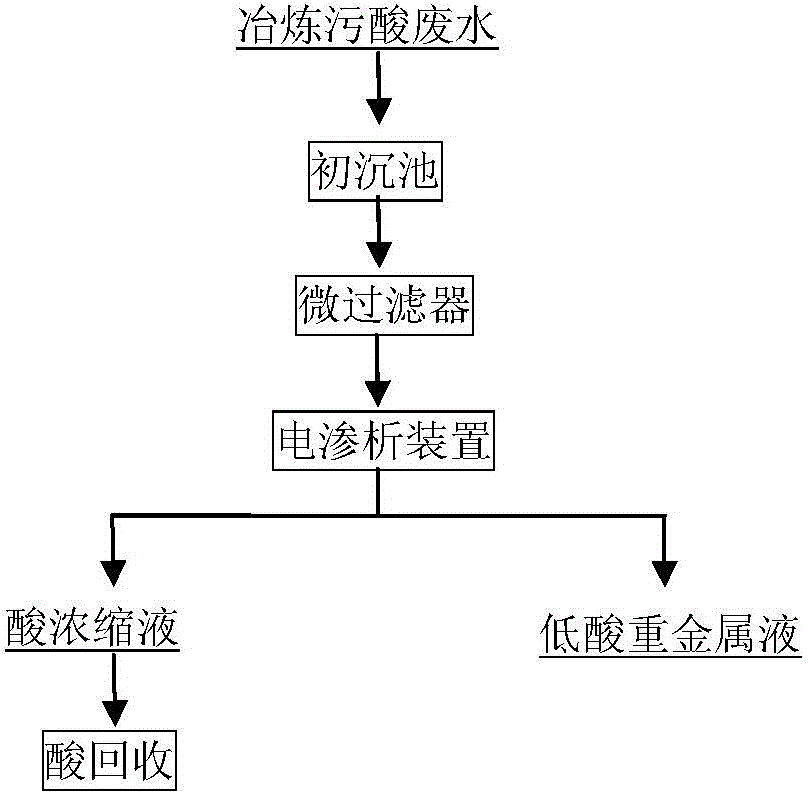

An acid concentration and fouling acid technology, which is applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc. The effect of facilitating the recycling environment, improving the recycling rate, and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

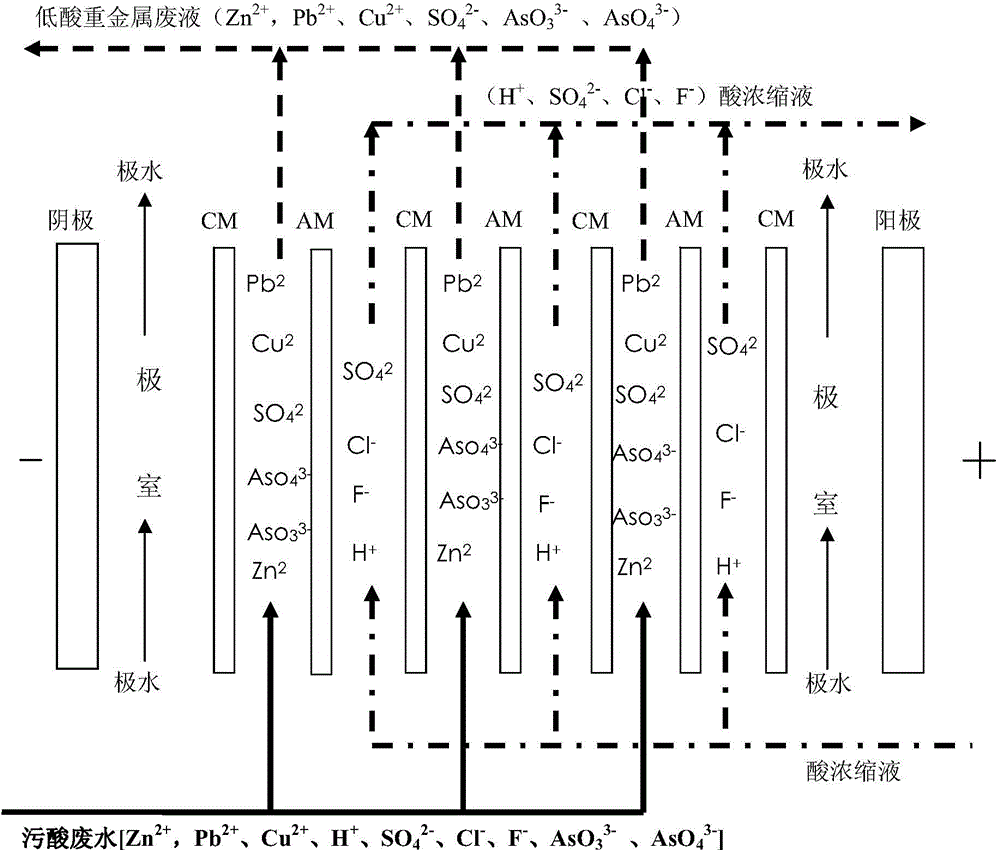

Embodiment 1

[0054] Example 1: Sewage acid from a lead-zinc smelter, acid mass fraction (calculated as sulfuric acid) 4.2%, zinc ion concentration 138mg / L, lead ion 34mg / L, arsenic concentration 113.3mg / L, separated by electrodialysis device for 20 minutes , The pH value of the original dirty acid solution rose to 3.2, the zinc ion concentration in the dirty acid solution was 137.5mg / L, the lead ion concentration was 33.75mg / L, and the arsenic concentration was 112.5mg / L; the mass fraction of the acid concentration in the separated concentrated solution was 8.3 %, zinc ion concentration is 0.38mg / L, lead ion concentration is 0.15mg / L, arsenic concentration is 0.45mg / L. The low-acid heavy metal liquid after acid separation passes through the sulfidation reactor. The recovery rate of zinc is 97.5%, and the recovery rate of lead is 95.4%.

[0055] The electricity consumption per cubic meter of dirty acid is about 10 degrees, the vulcanization process consumes 0.8kg of sulfide, and the treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com