Overcurrent protection method and overcurrent protection system of liquid crystal display panel

A liquid crystal display panel and protection system technology, applied in the direction of overcurrent protection, static indicators, instruments, etc., can solve problems such as overheating and burning, liquid crystal display panel damage, liquid crystal display panel damage, etc., to improve accuracy and timeliness, avoiding frequent startup, avoiding the effect of OCP frequent startup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

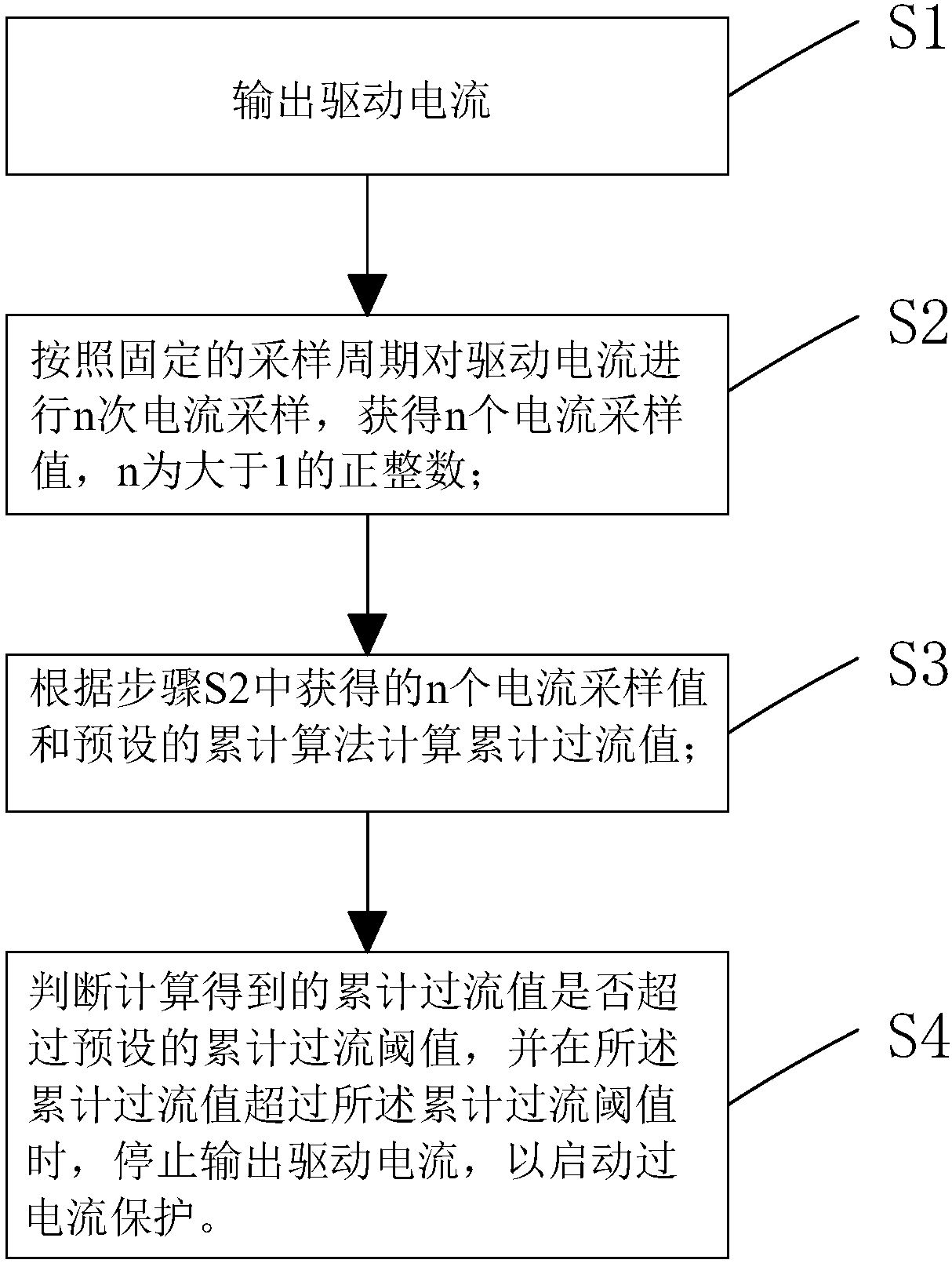

[0037] see figure 1 , the invention provides a method for overcurrent protection of a liquid crystal display panel, comprising the following steps:

[0038] Step S1, output driving current;

[0039] Specifically, the driving current is the current generated by the high voltage (VGH), the low voltage (VGL), or the common voltage (VCOM) of the liquid crystal display panel.

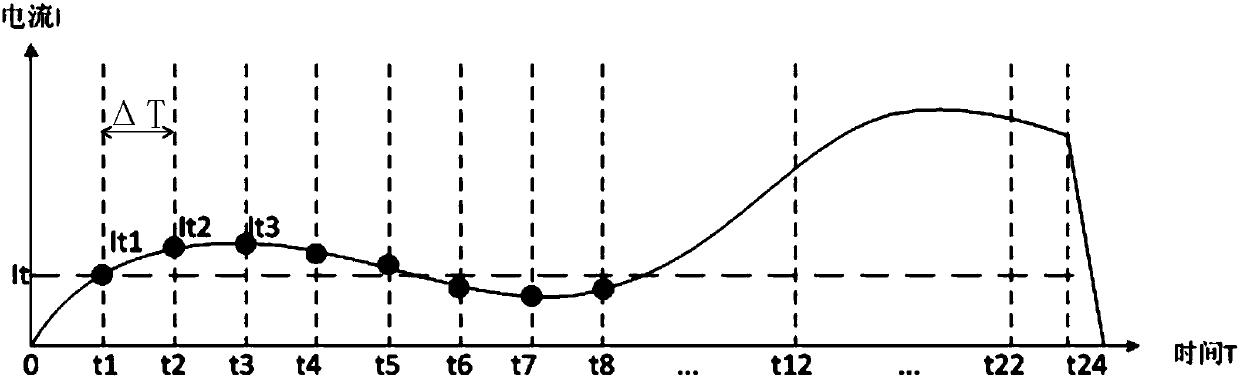

[0040] Step S2, performing n times of current sampling on the drive current according to a fixed sampling period within an overcurrent protection period to obtain n current sampling values, where n is a positive integer greater than 1;

[0041] Specifically, the driving current output in S1 is an analog signal, and the step S2 performs analog-to-digital conversion on the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com