Spray type nasal irrigator

A nasal irrigation and spray technology, applied in the field of medical devices, can solve the problems of inability to adjust the pressure and spray volume, no expected effect, and damage to the nasal mucosa, so as to avoid choking water and secondary lung infection, and reduce the residue of scale. , to avoid the effect of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Spray type nasal cavity irrigation device, its whole operation process is as follows:

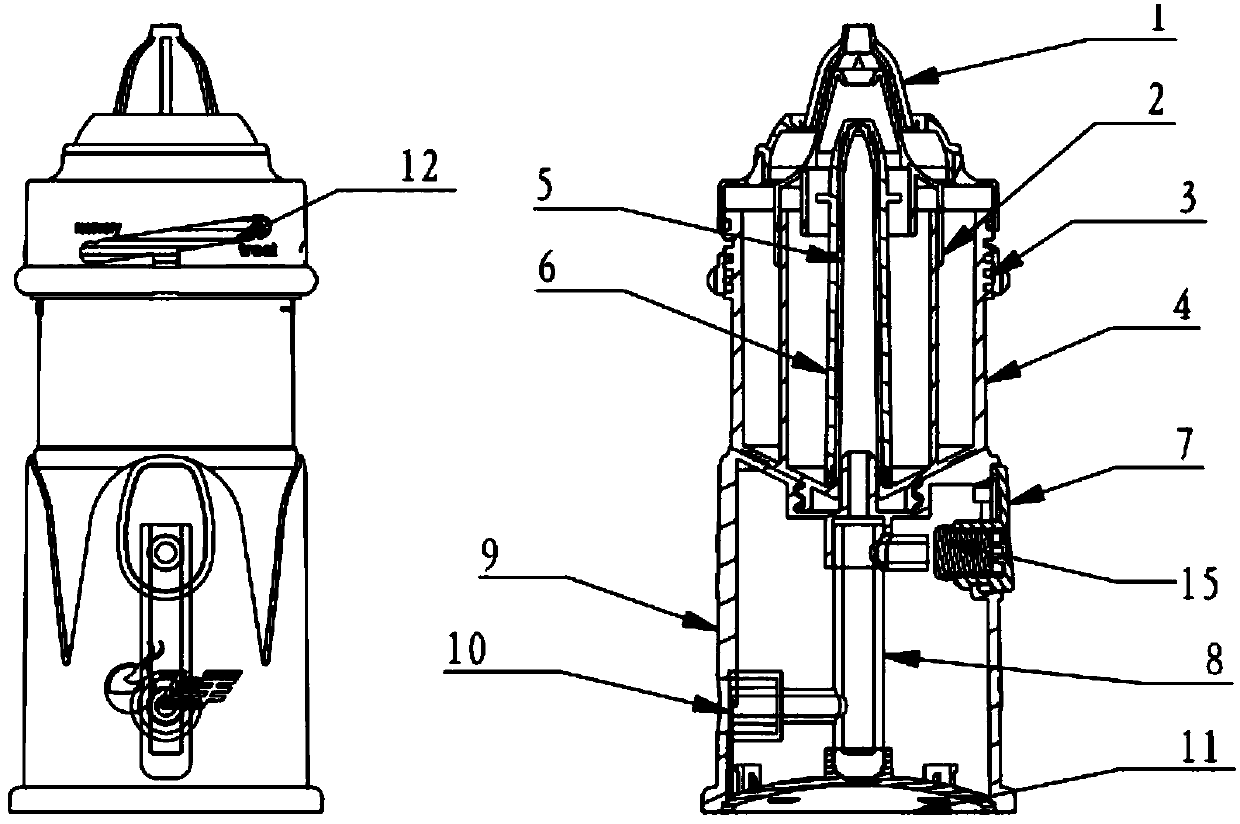

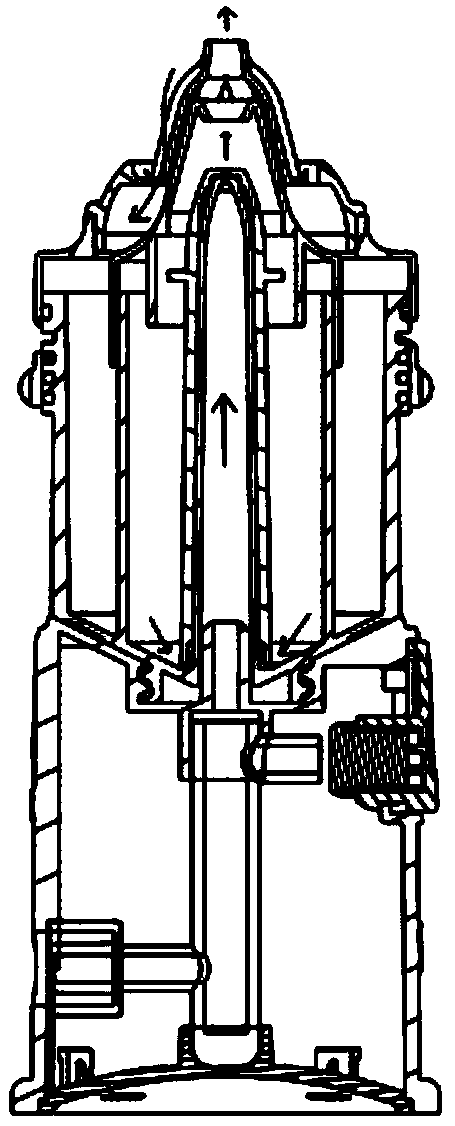

[0027] Such as figure 1 As shown, the spray nasal irrigator includes a nostril connector 1, a baffle plate 2, a separator 3, a tank body 4, an atomizing column 5, an atomizing cap 6, a switch button 7, an air pipe 8, a base 9, and an air intake Hole 10, bottom cover 11, up and down regulating valve 12, liquid medicine tank 13, waste liquid tank 14. When the compressed gas flows through the small hole at the upper end of the atomizing column 5 through the air inlet hole 10, a negative pressure will be formed between the atomizing column 5 and the atomizing cap 6, and under the action of atmospheric pressure, the The liquid medicine will flow along the liquid guide groove between the atomization column 5 and the atomization cap 6 to around the small hole, spray out with the small hole, and then spray out through the small hole of the atomization cap 6, forming an MMAD value of 48 micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com