Method for extracting thanakha

An extraction method and extract technology, which can be used in pharmaceutical formulations, solid solvent extraction, cosmetics, etc., can solve the problems of cumbersome extraction process and high energy consumption of Tanaka extract, and achieve significant ultraviolet absorption effect, strong safety, and overall The effect of high flavonoid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

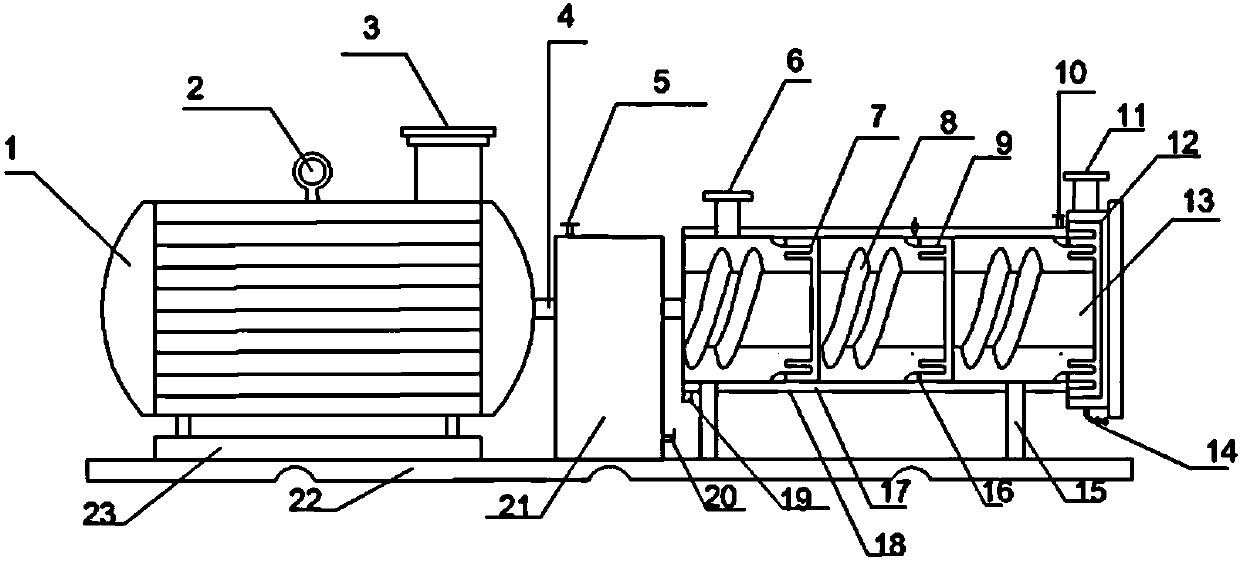

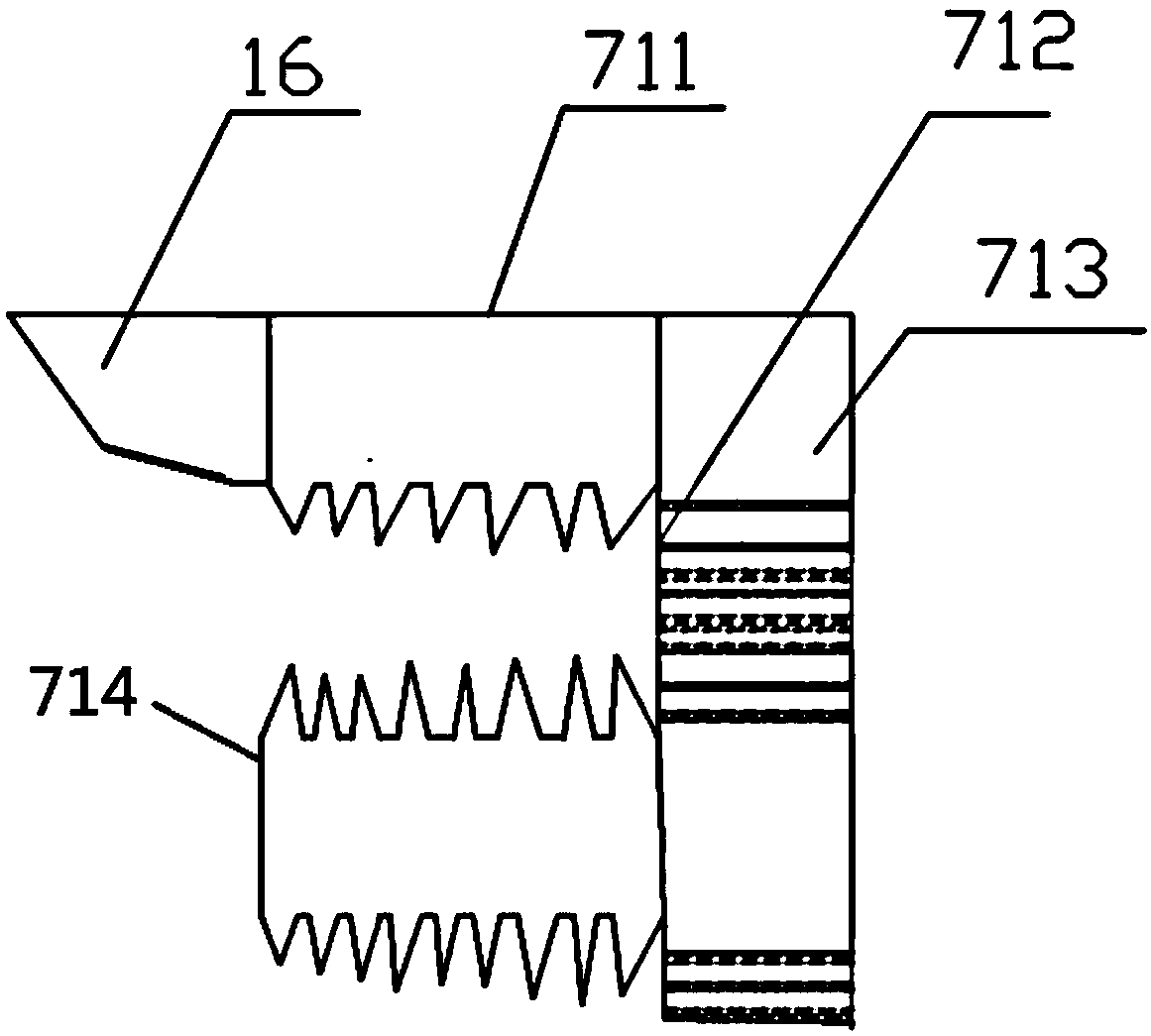

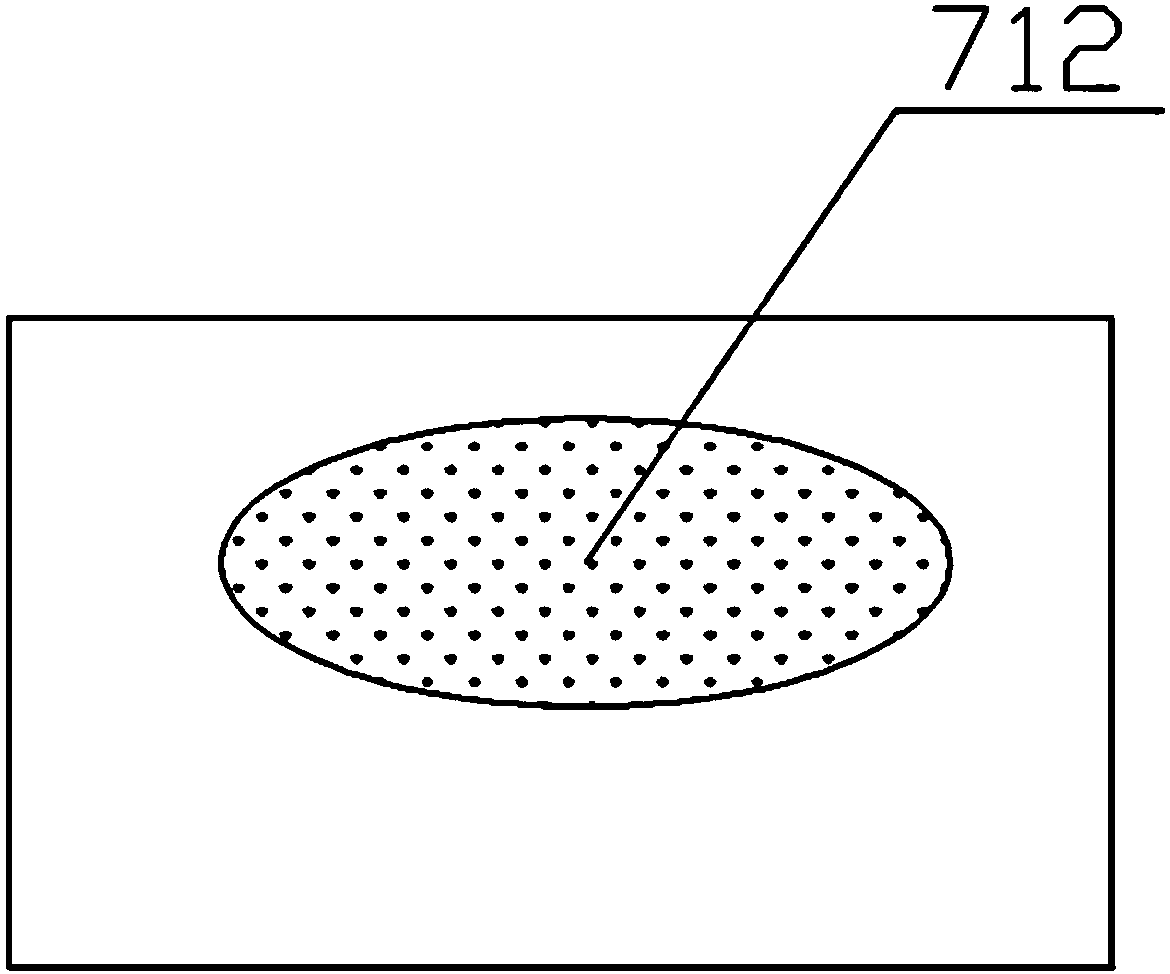

Method used

Image

Examples

Embodiment 1

[0114] 5kg Tanaka root is powdered, and crosses a 70-mesh sieve to obtain Tanaka powder with an average mesh number of 70. Add 150kg of 60% 1,3-butanediol solution to the Tanaka powder, stir evenly, and place In a microfluidic extractor, the extraction was carried out under the conditions of a refrigerant temperature of 20° C. and a feed rate of 20 L / min to obtain an extract.

[0115] The above extract was pumped into a high-speed centrifuge for solid-liquid separation at a centrifugal speed of 17000 rpm, and the separated liquid was collected. Then the separation liquid is pumped into the membrane treatment system, and the 0.5 μm microporous membrane and the 7000 Da ultrafiltration membrane are used to remove impurities and purify in sequence to obtain the membrane separation liquid.

[0116] Concentrate the above-mentioned membrane separation liquid under reduced pressure under reduced pressure. The conditions for concentrated under reduced pressure under reduced pressure ar...

Embodiment 2

[0118] 5kg Tanaka root is powdered and passed through a 80-mesh sieve to obtain Tanaka powder with an average mesh number of 80. Add 200kg of 20% 1,3-butanediol and 20% 1,2-butanediol to the Tanaka powder. The propylene glycol (w / w) mixed solution was stirred evenly, placed in a microfluidic extractor, and extracted at a refrigerant temperature of 30° C. and a feed rate of 5 L / min to obtain an extract.

[0119] The above extract was pumped into a high-speed centrifuge for solid-liquid separation at a centrifugal speed of 18000 rpm, and the separated liquid was collected. Then the centrifugate is pumped into the membrane treatment system, and the 0.4μm microporous membrane and 8000Da ultrafiltration membrane are used to remove impurities and purify in sequence to obtain the membrane separation fluid.

[0120] Concentrate the above-mentioned membrane separation liquid under reduced pressure under reduced pressure. The conditions for concentrated under reduced pressure under reduce...

Embodiment 3

[0122] 5kg Tanaka root is powdered and passed through a 40-mesh sieve to obtain Tanaka powder with an average mesh number of 40. Add 165kg of 30% 1,3-butanediol and 40% 1,2-butanediol to the Tanaka powder. The propylene glycol (w / w) mixed solution was stirred evenly, placed in a microfluidic extractor, and extracted at a refrigerant temperature of 10° C. and a feed rate of 20 L / min to obtain an extract.

[0123] The above extract was pumped into a high-speed centrifuge for solid-liquid separation at a centrifugal speed of 18000 rpm, and the separated liquid was collected. Then the centrifugate is pumped into the membrane treatment system, and the 0.3μm microporous membrane and the 9000Da ultrafiltration membrane are used to remove impurities and purify in sequence to obtain the membrane separation fluid.

[0124] Concentrate the above-mentioned membrane separation liquid under reduced pressure under reduced pressure. The conditions for concentrated under reduced pressure under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com