Laser welding machine for automobile part machining

A technology for laser welding machines and auto parts, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of insufficient fixation, large welding seam width, and welding seam offset, etc., to achieve tight connection, welding seam and other problems. Flat and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

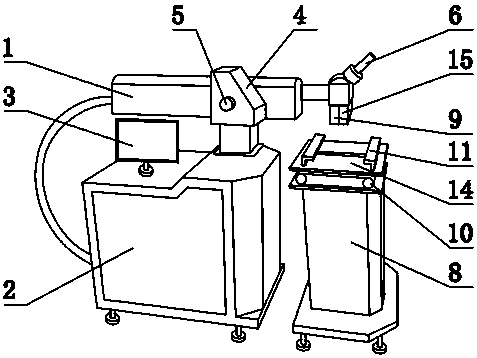

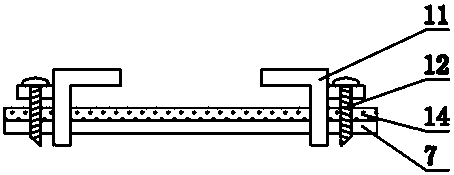

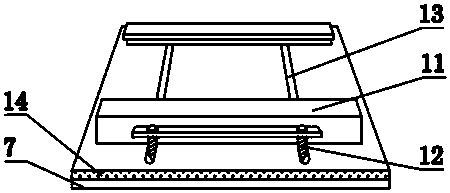

[0011] The present invention is a laser welding machine for auto parts processing, comprising a host 1, a chiller 2, an observation screen 3, a control panel 4, a switch button 5, a microscope 6, a workbench 7, a workbench base 8, a focusing lens 9, a conveyor belt 10, Fixture 11, fixture screw 12, fixture slideway 13, photosensitive plate 14, infrared generator 15, host 1 is installed above chiller 2, observation screen 3 is installed above chiller 1, observation screen 3 is located on the side of host 1, and on the side of host 1 The control panel 4 is installed on the side, the switch button 5 is installed on the side of the control panel 4, the microscope 6 is installed on the side of the host 1, the focusing lens 9 is installed under the microscope 6, and the infrared generator 15 is installed under the microscope 6, and the infrared generator 15 is located on the side of the focusing lens 9 On the side of the chiller 2, a workbench base 8 is installed. A conveyor belt 10 ...

Embodiment 2

[0013] When in use, lay the two pieces of weldment to be welded on the inside of the fixture 11, start the power supply, control the fixture 11 to slide along the fixture slideway 13 through the control panel 4, tighten the fixture 11 in a parallel direction, and the control panel 4 controls the fixture screw 12 to move forward. Turn clockwise, the clamp screw 12 drives the clamp 11 to move downward, and tightens the clamp 11 vertically. At this time, the two weldments are firmly stuck in the clamp 11. Press the switch button 5, and the laser in the host 1 is transmitted through the optical fiber. , collimated into parallel light, then converged by the focusing lens 9, and emitted at the gap between the two weldments, the conveyor belt 10 is controlled by the control panel 4 to drive the workbench 7 to drive at a constant speed, and the two weldments are driven accordingly, and the docking position of the weldments Pass under the focusing lens 9 at a constant speed, press the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com