Metal thin-wall pipe preparation method, metal thin-wall pipe fitting and cardiovascular stent

A technology of metal thin, walled tubes, applied in stents, medical science, prostheses, etc., can solve the problems of large tube wall thickness, inability to meet the standard of cardiovascular stents, low surface finish of the tube wall, etc., and achieve the effect of high smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

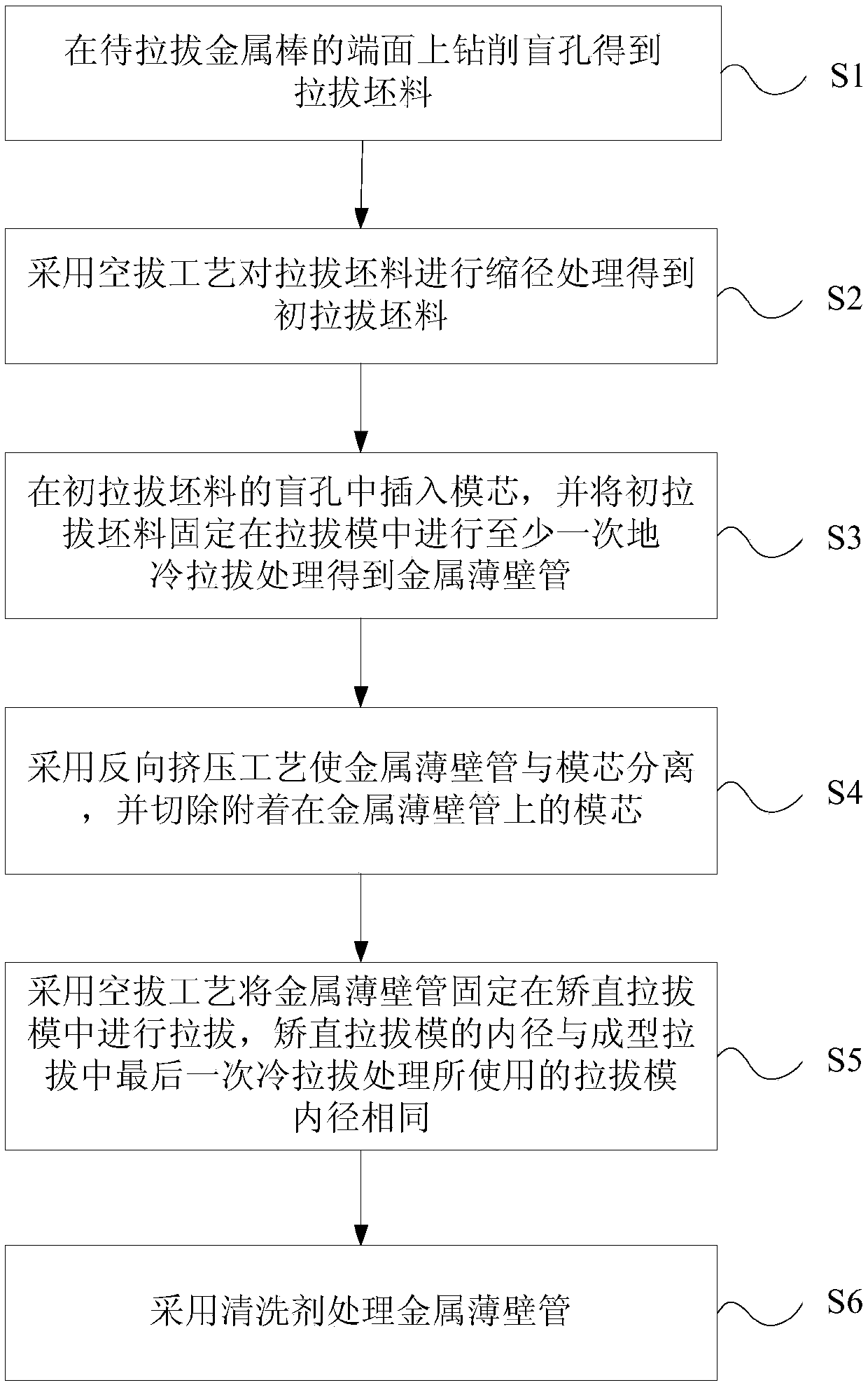

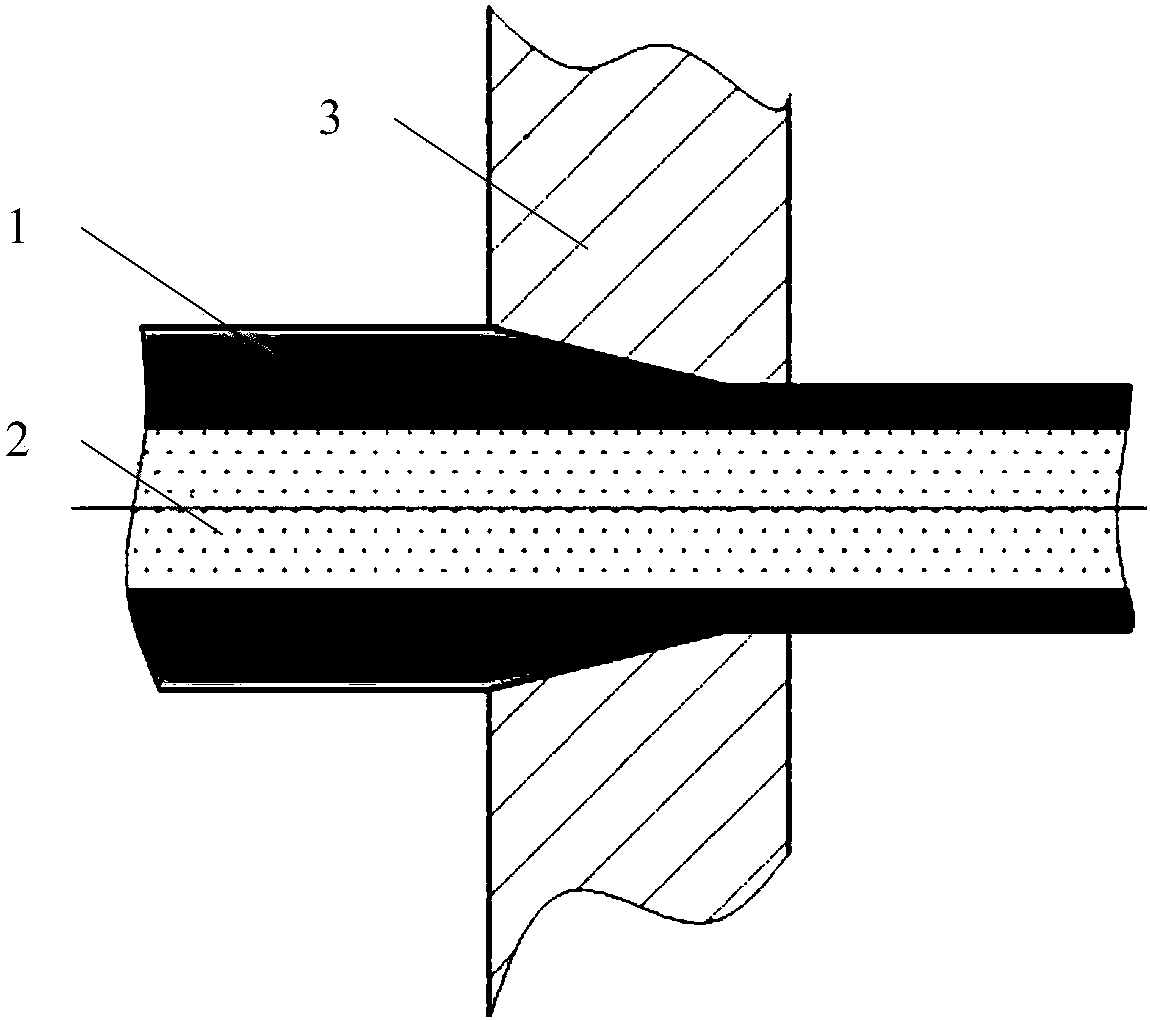

[0031] figure 1 It is a schematic flow chart of the method for preparing a metal thin-walled pipe provided in Embodiment 1 of the present invention. figure 2 It is a structural schematic diagram of a drawing die, a pre-drawing blank and a mold core in the method for preparing a metal thin-walled pipe provided in Embodiment 1 of the present invention.

[0032] At present, the methods of preparing metal thin-walled tubes mainly include drawing forming, extrusion forming and rolling forming, all of which use the characteristics of metal plastic deformation to apply a certain force to the metal blank to deform and reduce the cross-sectional area, and finally form a thin-walled tube. pipe fittings. However, the above-mentioned preparation method is extremely difficult to prepare metal pipes with a wall thickness of less than 0.3mm, and the surface roughness and strength of the finished pipes cannot meet the standards for the use of cardiovascular stents, so they are not suitable ...

Embodiment 2

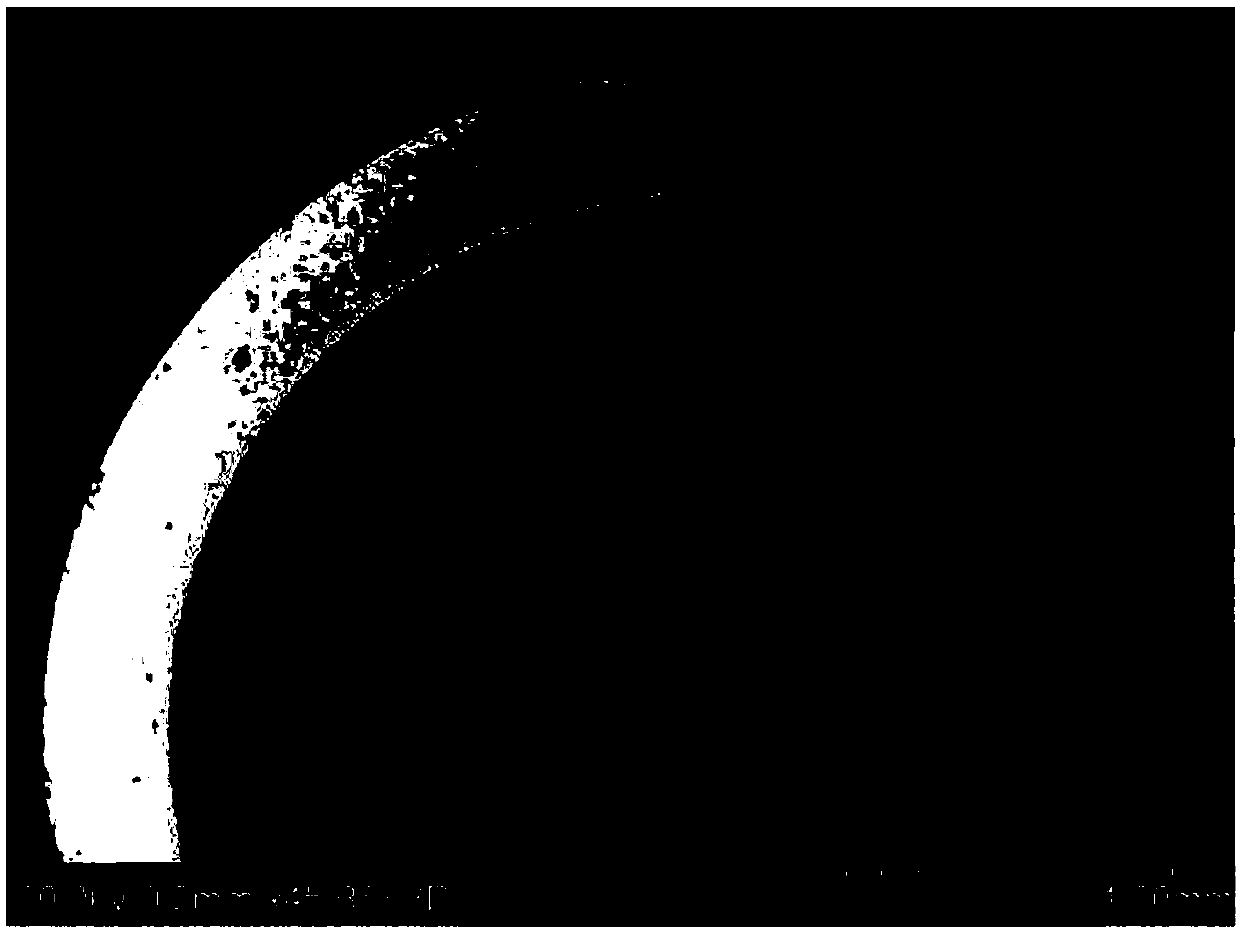

[0072] image 3 It is a scanning electron microscope diagram of the cross-section of the metal thin-walled pipe provided in Embodiment 2 of the present invention. Refer to attached image 3 As shown, Embodiment 2 of the present invention also provides a metal thin-walled pipe fitting, which is prepared by the above-mentioned metal thin-walled pipe preparation method.

[0073] It should be noted that the metal thin-walled pipe fittings can be extruded metal rods to be drawn, and a blind hole is drilled on the end face of one end to complete the pretreatment. diameter treatment to obtain a preliminary drawn blank with relatively uniform wall thickness, and then insert a mold core in the blind hole of the preliminary drawn blank, and perform at least one cold drawing process on the preliminary drawn blank in the drawing die to obtain Metal thin-walled pipe, the metal thin-walled pipe is only a pre-finished product, after which it needs to remove the mold core, straighten and dr...

Embodiment 3

[0077] The present invention also provides a cardiovascular stent, which is made of the above-mentioned metal thin-walled pipe.

[0078] It should be noted that the cardiovascular stent provided in this embodiment utilizes the metal thin-walled pipe provided in Embodiment 2 to make a cardiovascular stent by laser cutting and processing, wherein the shape and specific dimensions of the cardiovascular stent are based on the Cardiovascular stents are designed to be located in different parts of the human body. In this embodiment, the metal thin-walled tube may be a thin-walled tube of magnesium or magnesium alloy, which has good biocompatibility and can ensure that the cardiovascular stent has minimal side effects on the human body.

[0079] Other technical features are the same as those in Embodiment 1 or Embodiment 2, and can achieve the same technical effect, and will not be repeated here.

[0080] In the cardiovascular stent provided by Embodiment 3 of the present invention, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com